2~6 mm thickness cladding layer laser cladding technology

Time:2023-07-12

Views:353

Laser cladding for 2~6mm thickness on mill roll

What is laser cladding can do?

Laser cladding technology refers to the process of placing selected coating materials on the surface of the coated substrate using different filling methods, which are irradiated by laser to melt simultaneously with a thin layer on the substrate surface, and rapidly solidify to form a surface coating with extremely low dilution and metallurgical bonding with the substrate material, thereby significantly improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties of the substrate material surface.

Laser cladding is the main alloy of the alloy powder that needs to be melted into the cladding layer without laser. The cladding layer and the base metal are melted in a thin layer to form a metallurgical combination of laser surface repair treatment technology.

Laser cladding technology refers to the process of placing selected coating materials on the surface of the coated substrate using different filling methods, which are irradiated by laser to melt simultaneously with a thin layer on the substrate surface, and rapidly solidify to form a surface coating with extremely low dilution and metallurgical bonding with the substrate material, thereby significantly improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties of the substrate material surface.

Laser cladding is the main alloy of the alloy powder that needs to be melted into the cladding layer without laser. The cladding layer and the base metal are melted in a thin layer to form a metallurgical combination of laser surface repair treatment technology.

Today Howweld team share with cladding process on our web.

Testing sample: S205 metal circular column

Diameter: 100mm

Weight: 4.1kg

Length: 205mm

Test time_Howweld: 2023-6-22Diameter: 100mm

Weight: 4.1kg

Length: 205mm

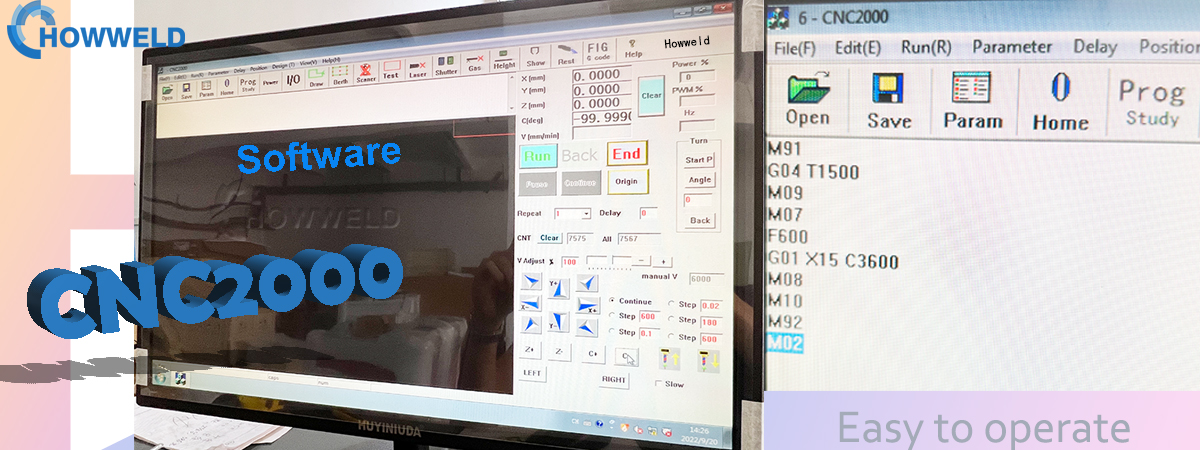

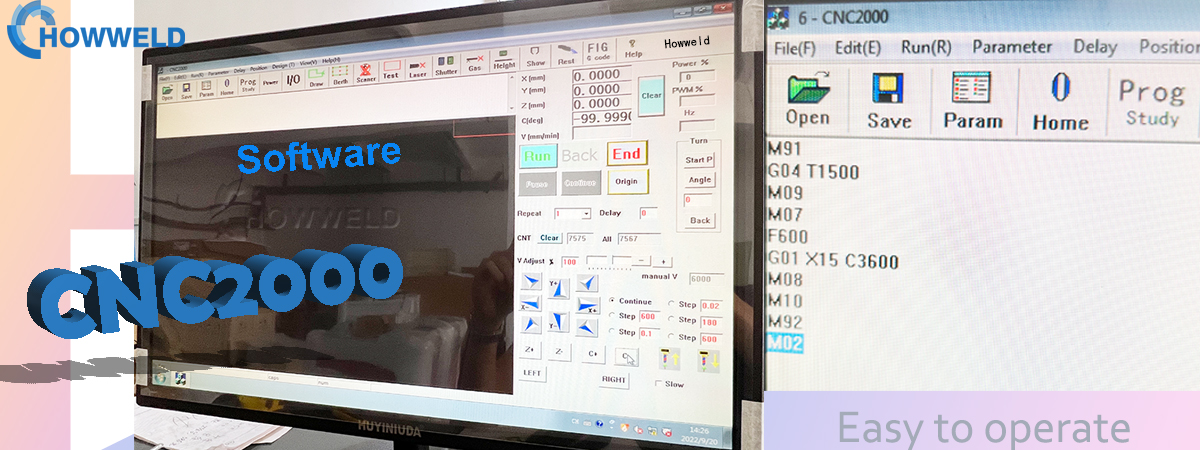

Machine power: CNC 6KW laser cladding machine.

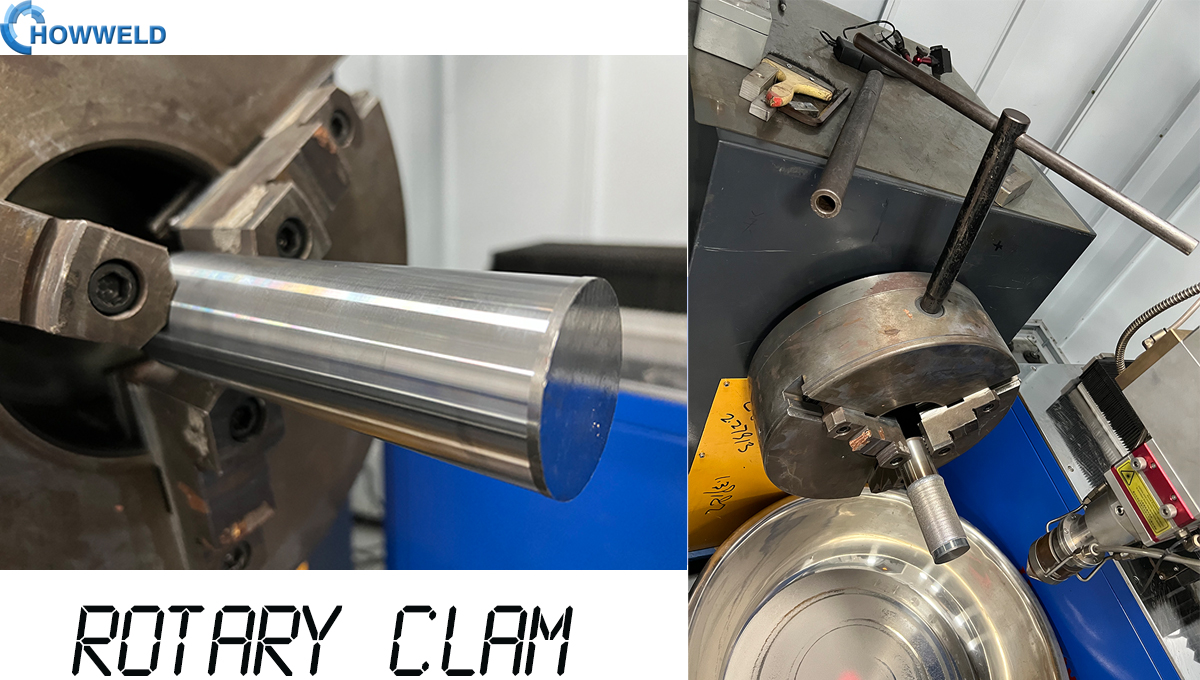

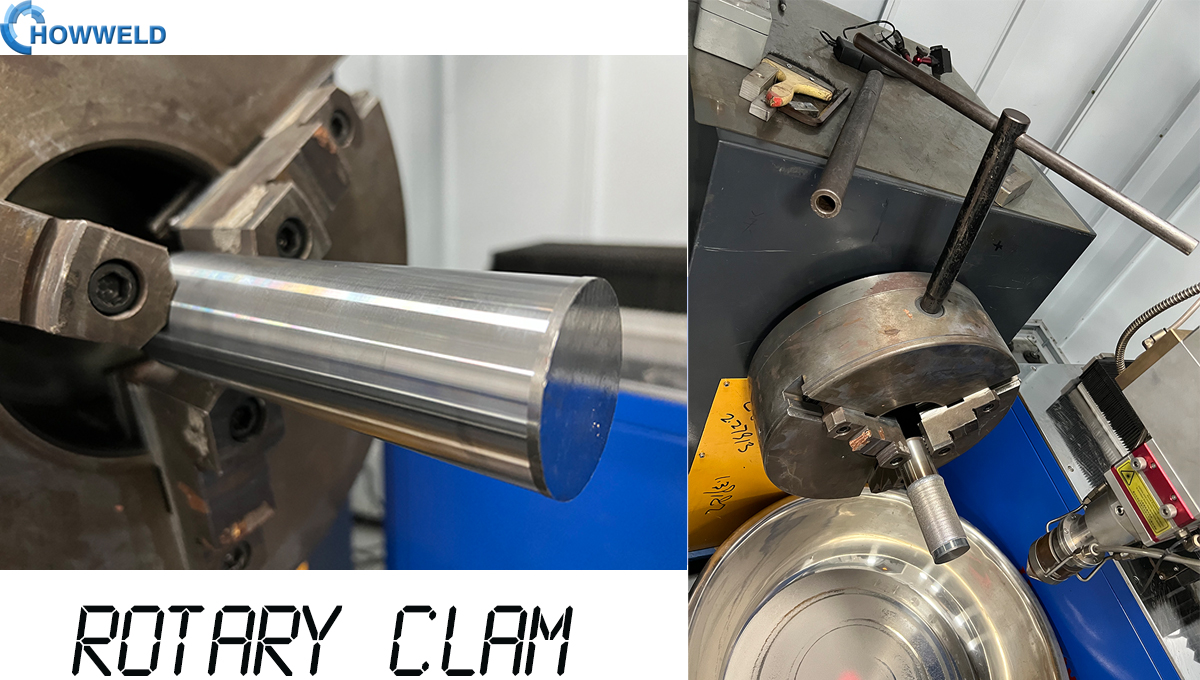

Raycus laser with rotary type.

Rotary can clamp 800mm diameter. Weight can max load 1 ton.

Raycus laser with rotary type.

Rotary can clamp 800mm diameter. Weight can max load 1 ton.

Materials: S205 model

Cladding requirements: at least 2mm, max 6mm

Cladding powder: S316

Before cladding:

Clamp on the rotary:

CNC software to operating to clad on surface:

Cladding video:

Test parameter:

Cladding speed: 600mm/s

Laser power: 30%

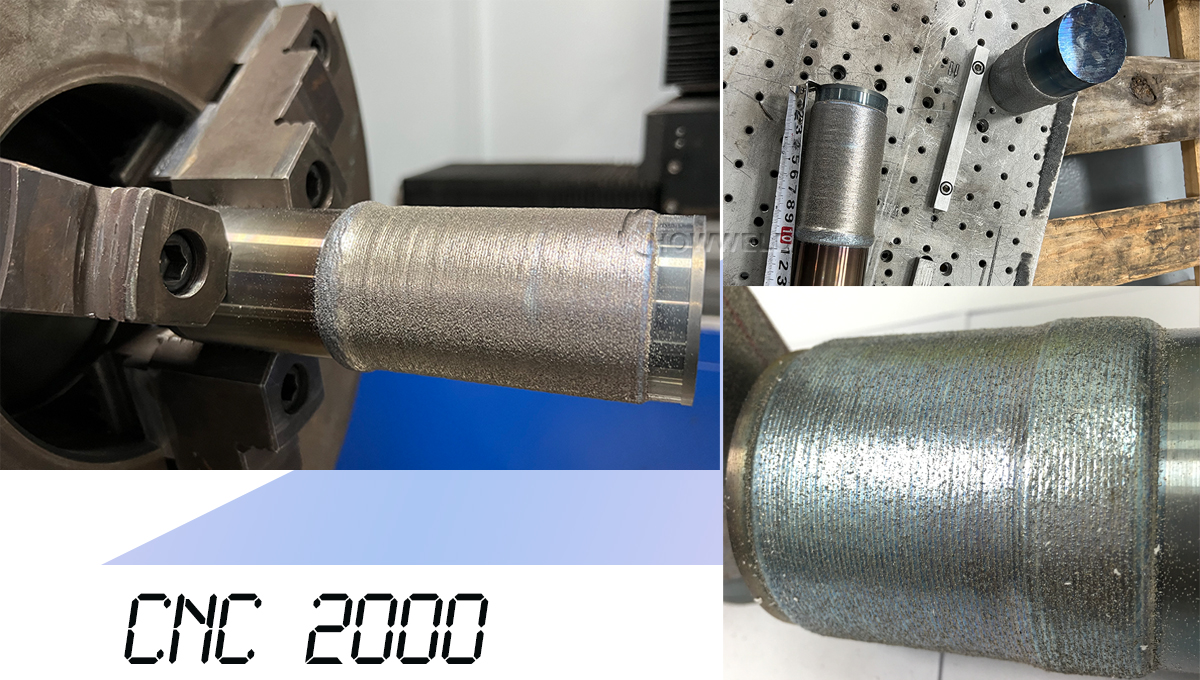

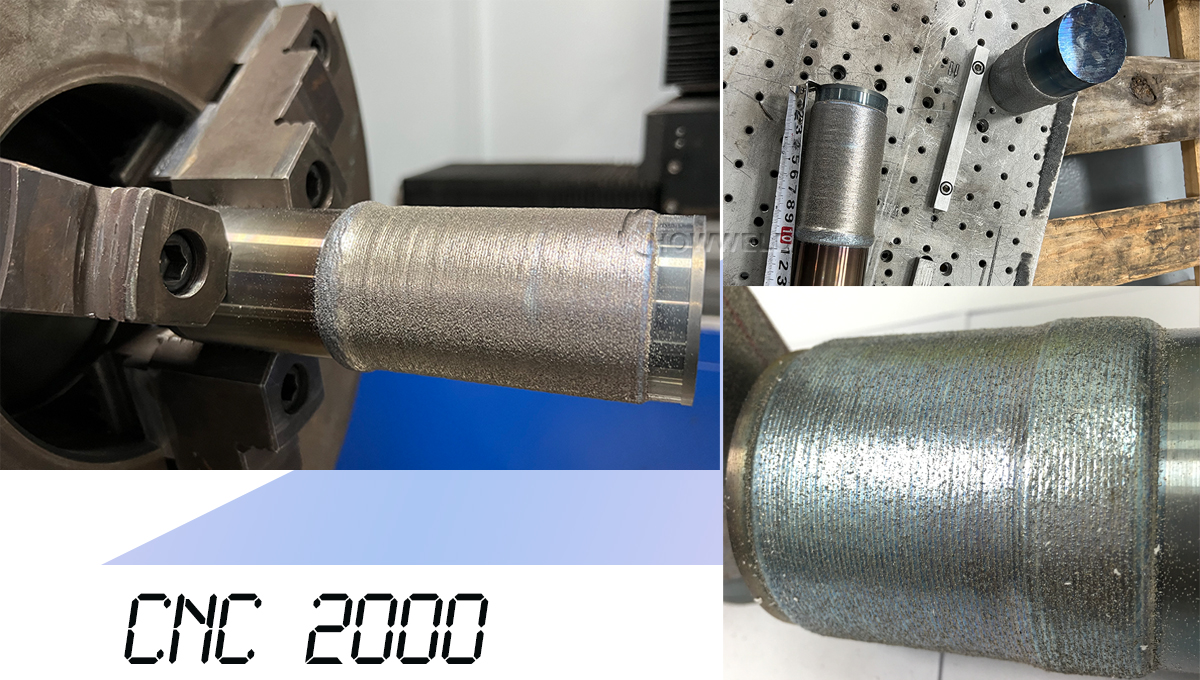

After cladding:

Cladding powder: S316

Before cladding:

Clamp on the rotary:

CNC software to operating to clad on surface:

Cladding video:

Test parameter:

Cladding speed: 600mm/s

Laser power: 30%

After cladding: