Bearing seat repair laser cladding repair additive manufacturing

Time:2024-10-21

Views:191

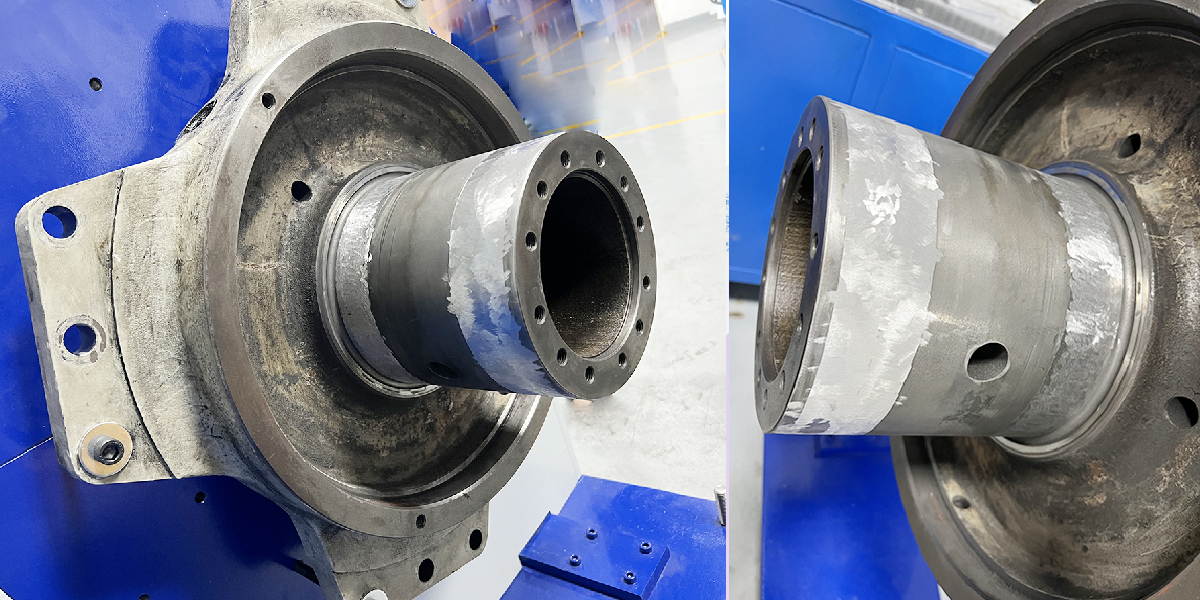

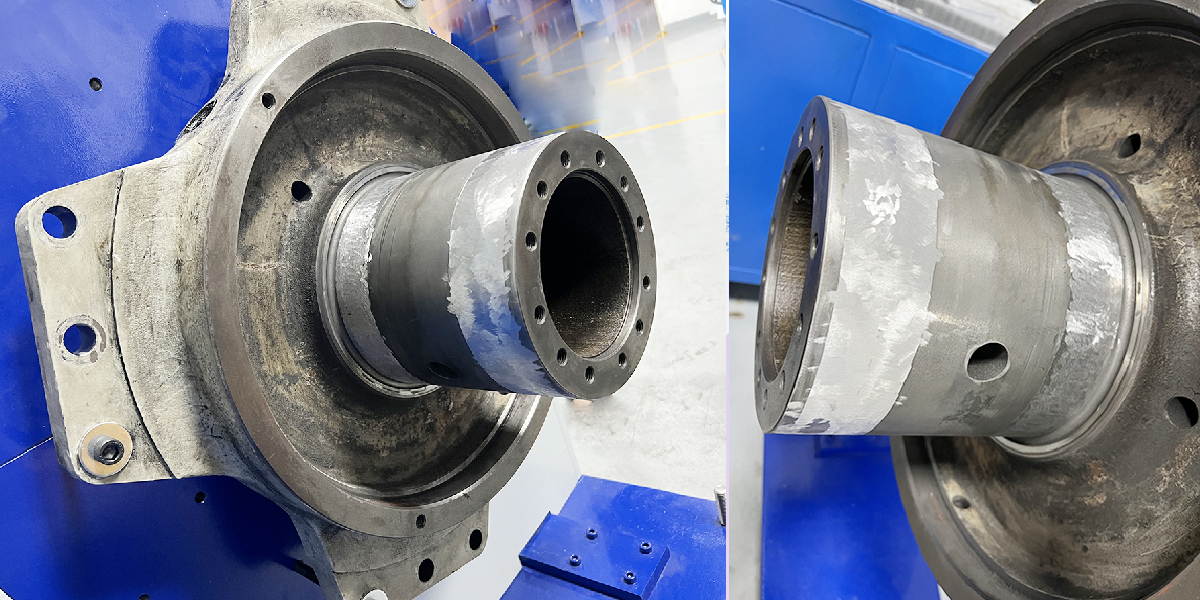

Re-manufacture for main shaft bearing seat steel base

Laser cladding technology is a new technology with high economic benefits. It can prepare high-performance alloy surfaces on inexpensive metal substrates without affecting the properties of the substrate, reducing costs, and saving precious and rare metal materials. Therefore, advanced industrial countries around the world attach great importance to the research and application of laser cladding technology. The application of laser cladding is mainly in two aspects, namely corrosion resistance (including high temperature corrosion resistance) and wear resistance. It has a wide range of applications, such as the sealing surfaces of valves and valve seats in internal combustion engines, laser cladding of water, gas or steam separators, etc.

The application of laser cladding repair involves metallurgy, electric power, petroleum, chemical industry, ship, locomotive, coal machine, automobile and other pillar industries of the national economy. According to the operating conditions of different equipment, laser surface remanufacturing (fusion repair, additive manufacturing) mainly improves the wear resistance, corrosion resistance, high temperature resistance, oxidation resistance and other properties of metal parts. It can not only restore the use of expired parts, but also significantly extend the service life of new parts.

Laser cladding technology can improve the hardness, wear resistance, corrosion resistance, and fatigue resistance of metal parts, extend the service life of materials, and can also be used for repairing worn parts, saving processing costs. The application of laser cladding technology in the manufacturing of aircraft components can reduce the manufacturing process of workpieces, improve the quality of components, and greatly increase the service life of components.

Key words: High speed laser cladding of hydraulic support, Laser cladding of large gears, Laser repair of large molds, Side guide plate laser cladding

Laser cladding machine for re-manufacture, laser cladding system for repair shaft roller bearing 3000w laser cladding machine 6000w laser cladding machine

Robot laser cladding machine

Laser cladding technology can improve the hardness, wear resistance, corrosion resistance, and fatigue resistance of metal parts, extend the service life of materials, and can also be used for repairing worn parts, saving processing costs. The application of laser cladding technology in the manufacturing of aircraft components can reduce the manufacturing process of workpieces, improve the quality of components, and greatly increase the service life of components.

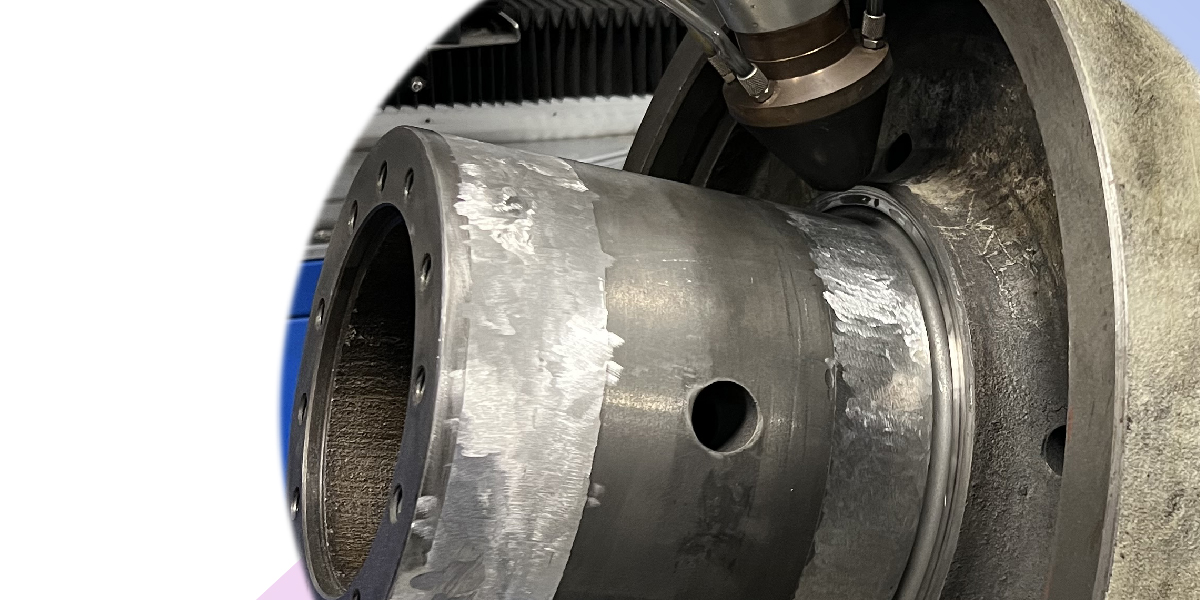

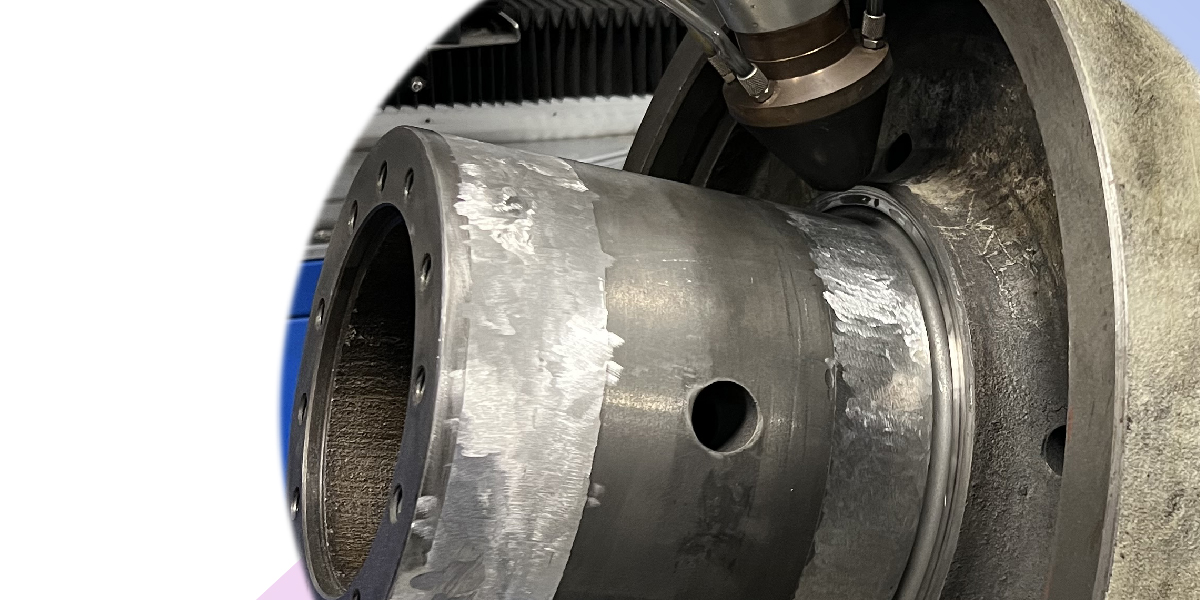

Test parameter:

Cladding speed: 500mm/s

Laser power: 36%

Today Howweld team share with cladding process on our web.

Testing sample: steel alloy metal

Diameter: 760mm

Weight: 188kg

Height: 60mm

Test time_Howweld: 2024-10-10

Machine power: CNC 6KW laser cladding machine.

Raycus laser with rotary type.

Rotary can clamp 1250mm diameter.

Weight can max load 1 ton.

Cladding requirements: at least 3mm, max 6mm

Cladding powder: S316

Key words: High speed laser cladding of hydraulic support, Laser cladding of large gears, Laser repair of large molds, Side guide plate laser cladding

Laser cladding machine for re-manufacture, laser cladding system for repair shaft roller bearing 3000w laser cladding machine 6000w laser cladding machine

Robot laser cladding machine