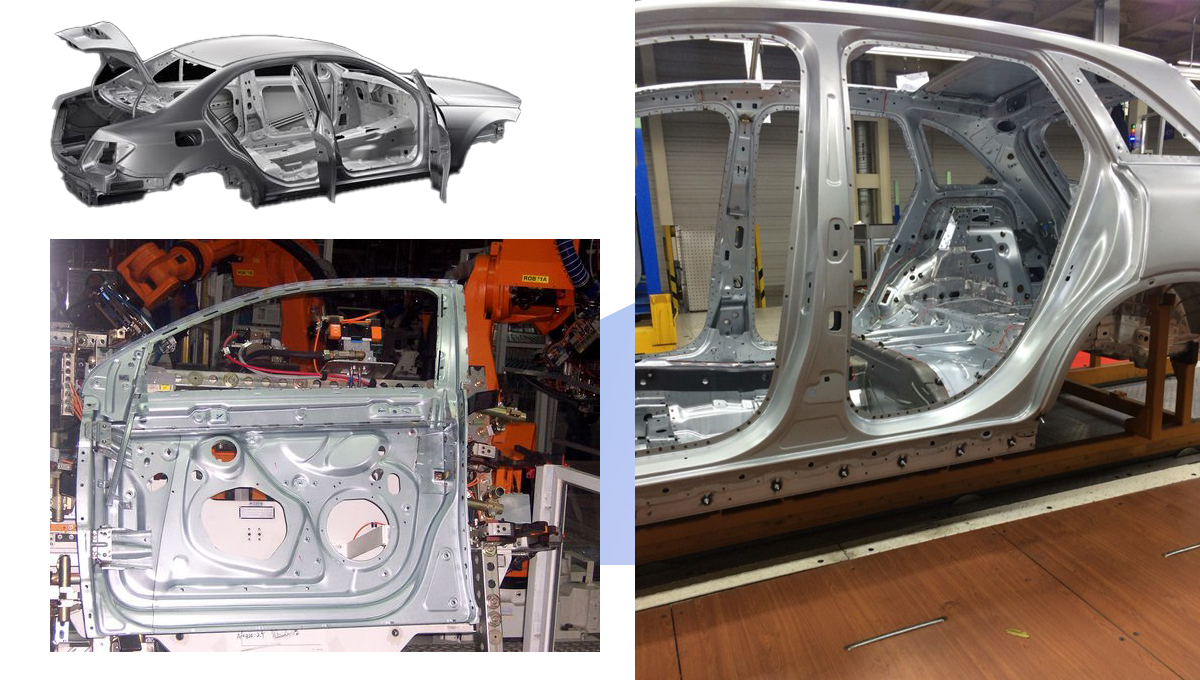

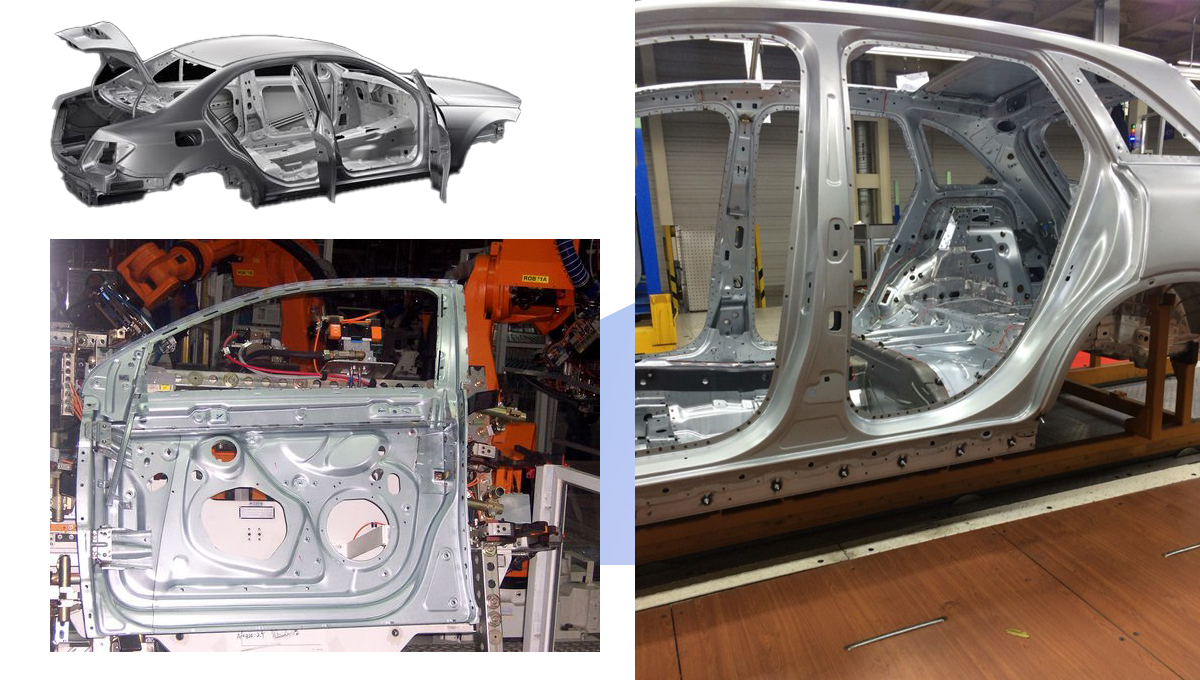

New energy vehicles body frame structure welding

Time:2024-01-17

Views:649

Laser welding of car body refers to the use of laser technology to weld car body products, which have higher strength and hardness compared to ordinary welding.

Laser welding technology is mainly used for splicing and welding of unequal thickness plates on car bodies. Laser welding is mainly used for the welding of vehicle frame structures, such as the welding of the top cover and side panels. Laser welding applied to automobiles can reduce body weight and achieve fuel efficiency; Improve the assembly accuracy of the vehicle body, increase the stiffness of the vehicle body by 30%, thereby improving the safety of the vehicle body; Reduce stamping and assembly costs in the manufacturing process of car bodies, reduce the number of body parts, and improve the degree of body integration.

Since the 1980s, laser welding technology has been applied in the field of automotive body manufacturing, mainly in laser welding of vehicle bodies. Laser technology uses a polarizing mirror to reflect the light beam generated by the laser and concentrate it in the focusing device to produce a beam of enormous energy, causing the workpiece to melt instantly, thus achieving the welding process.

The advantages of laser welding are firstly that the deformation of the workpiece being welded is extremely small, there is almost no connection gap, and the welding depth/width ratio is high. When welding high-power devices, the depth/width ratio can reach 5:1, and the highest can reach 10:1. The welding quality is better than traditional welding methods;

Secondly, the welding seam has high strength, fast welding speed, narrow welding seam, and usually has a good surface condition, eliminating the need for post weld cleaning and other work. Its appearance is more beautiful than traditional welding; In addition, laser welding can weld difficult to access areas and implement non-contact remote welding, which has great flexibility.

The application of laser welding in white body manufacturing mainly includes ordinary laser welding, laser brazing, laser remote welding, etc. The ordinary laser welding process is mainly used for roof welding, which can reduce noise and adapt to new vehicle structure designs.

Laser brazing is similar to traditional MIG brazing in that it uses a laser source to melt the welding wire, fill the weld seam, and form a welded joint. Remote laser welding is a non-contact welding method that uses a specialized lens to focus the laser on the welding workpiece at a distance of 1-2 meters. The lens is driven by a robot and can flexibly achieve welding of various parts through robot movement and changes in laser focus. Chinese brand car Xiaopeng Automobile Manufacturing Plant they had our [Howweld]3kw manual welding system, to weld new energy vehicles body frame structures. To test welding system last for 3 months, machine system pass the test and works quite stable. Welding penetration, Welding firmness, Deformability index, Integration level, Sealing performance etc various indicators had pass testing.