The important way of automobile lightweight,handheld laser welding machine

Time:2021-04-30

Views:1343

Realization of automobile lightweight: handheld laser welding and laser cutting

The important way of automobile lightweight;handheld laser welding machine

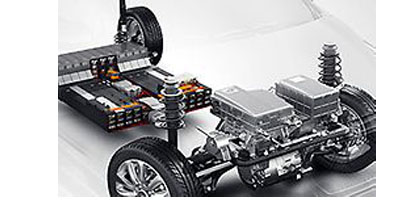

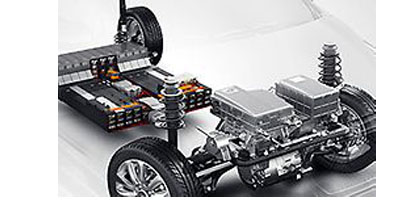

At present, with the adjustment of energy structure and the improvement of environmental protection requirements, the automotive industry is developing towards the direction of lightweight. Some data show that every 10% decrease in vehicle quality will reduce fuel consumption by about 3% ~ 5%. Automobile lightweight can not only effectively reduce energy consumption and increase the use function of automobile, but also reduce the production cost and improve the quality of automobile.

An important way to realize automobile lightweight

Of course, car lightweight is not just a simple matter of reducing the weight of the car, but in ensuring the quality of the car, more new materials are used in the functional parts and structural parts of the car, so that the performance of the car parts is more excellent and the weight is lighter, so as to reduce the energy consumption in the driving process of the car and achieve multiple effects.

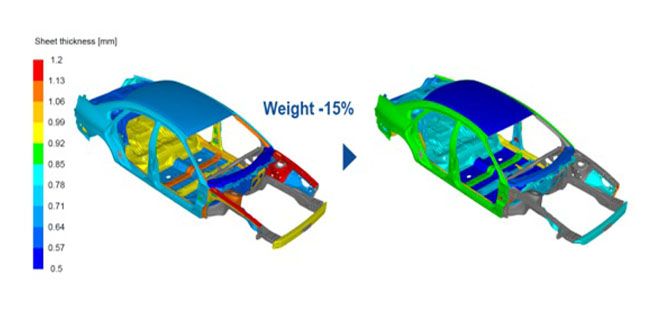

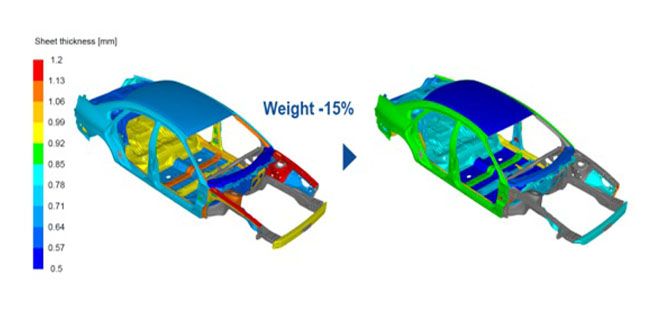

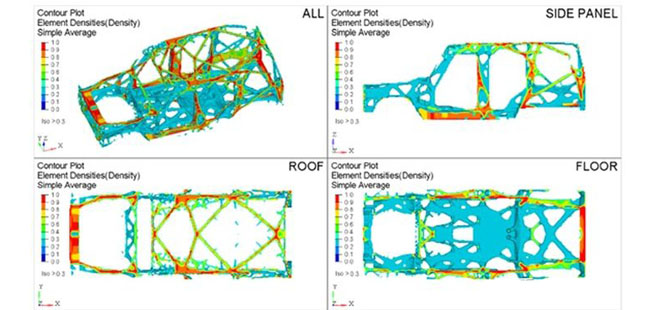

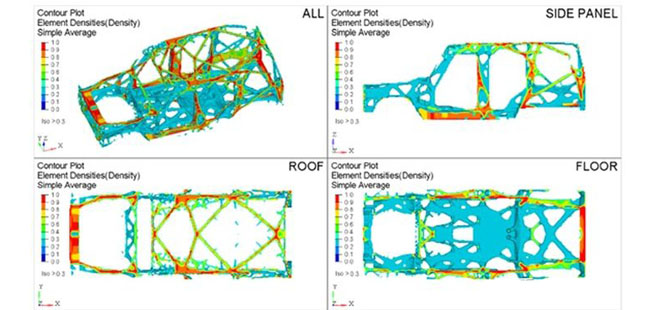

Corresponding to the decline of automobile quality, automobile lightweight technology is mainly realized through the following ways: the proportion of lightweight materials is rising, the application of aluminum alloy, magnesium alloy, titanium alloy, high strength steel, plastic, powder metallurgy, ecological composite materials and ceramics, etc; The level of structural optimization and modular design of components is constantly improving, such as the use of front wheel drive, high rigid structure and ultra light suspension structure to achieve the purpose of lightweight, the development of computer-aided integration technology (including CAD / CAE / CaO) and structural analysis technology; To promote the automobile manufacturing industry in the forming method and connection technology innovation.

In the above three ways to realize automobile lightweight, the processing of new materials, the design and formation methods of automobile structure and modularization, and the progress of connection technology all need corresponding process innovation. In these three ways, laser cutting and laser welding have become the important technical means to realize the lightweight of automobile with their unique advantages.

Laser welding and laser cutting innovate Lightweight Technology

Automobile manufacturing is a huge system engineering, which needs a series of technology to complete. In recent years, advanced technologies such as laser processing, industrial robot and digital control are constantly promoting the upgrading of automobile manufacturing industry. As an advanced processing method, laser is destined to bring revolutionary breakthrough to the development of automobile manufacturing industry. At present, laser technology in automobile manufacturing mainly focuses on laser welding, laser cutting, laser weakening, laser marking, laser resistance adjustment and laser remanufacturing.

The most important advantage of laser in automobile manufacturing lies in its advanced non-contact processing method, which plays an important role in the innovation of processing technology in the fields of auto body in white, automotive electronics, steel processing and so on. In the application of aluminum alloy, magnesium alloy, titanium alloy and other new materials, compared with the previous cutting methods, laser cutting has faster efficiency and higher precision, and for these difficult to machine materials, laser cutting is easier to realize. The progress of laser technology also makes the application of these new materials from ideal to reality, so that the new materials can be realized in the automotive lightweight.Handheld laser welding equipment can weld for 0.2mm to 6mm stainless steel,aluminium sheets.

Structuralization and modularization is to integrate the scattered parts in traditional automobile manufacturing, and realize the original functions of automobile from the integrity, so as to reduce the weight and realize the lightweight. The realization of structure and modularization, to a large extent, depends on the progress of connection technology. Some of the traditional production methods rely on screw fastening, and some rely on adhesive connection. The traditional methods can not meet the requirements of precision and firmness in modern automobile manufacturing, and the application of new materials also makes the traditional methods slightly inferior. Laser welding is non-contact. In the process of processing, precision welding can be realized without touching the product. It has achieved great progress in the process of connection firmness, seamless, precision and cleanliness, and will become an important forming method in the future.

Laser technology plays an important role in vehicle lightweight, which greatly improves vehicle performance and safety. In the future, laser technology has a broad application prospect in the automotive field.

Munich Shanghai Light Expo provides you with the most advanced laser technology

The market demand for laser technology has also led to the great development of the laser industry. More and more enterprises are actively developing and innovating laser technology. As a world-famous Laser Application Expo, Shanghai Light Expo Munich will gather many well-known laser enterprises in the world to present the audience with a full range of laser assisted vehicle lightweight solutions.

A special laser production and processing technology zone will be set up at the Munich Shanghai Optical Expo on March 14, 2017, which will bring together many laser enterprises, such as Han laser, Huagong laser, Shengxiong laser, Ted laser, Pentium truking, and cooperate with abb, fanako, stauber, KUKA and other automatic enterprises to present laser processing technology in automation field to the audience. At the same time, the "automobile theme route" was held to show the innovative products and technologies of laser technology upstream and downstream, opening a unique automobile technology journey for automobile professional users. At that time, audiences from BYD, SAIC Volkswagen, JAC, Geely and other well-known automobile enterprises will come to learn about the application of cutting-edge laser technology in automobile lightweight.

Laser processing technology is one of the important ways to realize automobile lightweight. In order to make better use of laser technology in the future, it is necessary to systematically study the basic theory of laser material interaction mechanism, non-destructive detection and control of laser processing process, and establish the optimization database of laser processing methods and process parameters; Research the laser cutting methods of different materials, carry out the theoretical research of laser cutting, welding, fine ablation, direct rapid prototyping, laser coating, laser assisted cutting, develop laser 3D cutting technology, establish process parameter database and expert system; Research the theory of laser deep penetration welding, develop the laser 3D welding technology and equipment; The laser processing and welding technology and equipment of different thickness, different automotive materials, especially lightweight materials are studied.

Automobile is becoming more and more important in people‘s life. It has gradually become a mobile living and office place from a single travel tool, which catalyzes the development of automobile towards intelligent, high-end and diversified direction. At the same time, with the increasing prosperity of the domestic economy and the improvement of environmental protection standards, the national demand for automobiles is increasing year by year. At the same time, the demand for environmentally friendly automobiles will also be more vigorous. When realizing this requirement, laser welding and laser cutting will play an increasingly important role.Howweld