5 Common Applications of Laser Engraving

Time:2022-03-31

Views:890

5 Common Applications of Laser Engraving

Laser engraving represents one of the most versatile and accessible forms of marking available. For this reason, contractors, industrial manufacturers, site managers and even homeowners use this process for applications in a variety of industries.

Even if you don‘t work in a commercial or industrial setting, you‘ve probably seen laser engraved signs, mementoes or awards.

In this blog, we discuss the five most common applications of laser engraving and when you might want to hire a professional to provide these services.

1. Awards and Trophies

Laser engraving creates clean, easily legible, shaped carvings directly onto a surface. This feature makes this engraving method preferable to paint, stain or emboss.

Most award and trophy makers rely on laser engraving for an array of materials, such as:

Glass

Metal

Wood

Additionally, many types of laser engravers can cut shapes into sturdy rubber to create custom stamps. These stamps work well for award certificates, as well as mass signatures, letterheads and other decorative markings.

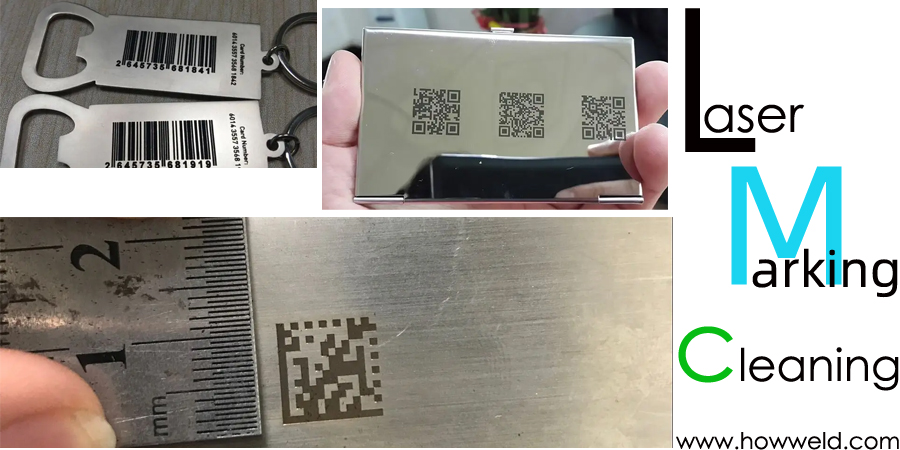

2. Barcode Creation

You see a lot of items with barcodes on them, from your weekly groceries to your industrial equipment components. Most barcodes you encounter are simply printed on paper or directly onto the item. However, items with specific characteristics won‘t take these standard barcodes.

Engravers cut barcodes directly into these items to avoid problems with any of the following characteristics:

Adhesive-resistant surfaces

Extremely large items

Heavy duty use which would wear down a standard barcode

In addition to barcodes consisting of lines of several different weights, engravers may cut QR codes, unique identification markers or similar markers onto these items.

Howweld team design many kinds laser engraving solution expecially for eyewear metal frames engraving,Kitchenware or metal cabinet surface logo,letters,pictures marking.Surface treatment.And also metal sheets welding.

Howweld team design many kinds laser engraving solution expecially for eyewear metal frames engraving,Kitchenware or metal cabinet surface logo,letters,pictures marking.Surface treatment.And also metal sheets welding.

3. Decorative or Commemorative Annotations

If you have purchased fine jewellery for someone special in your life, you‘ve likely considered engraving a date or phrase into the surface. Many retailers offer the options of including a decorative or commemorative annotation on a gift.

You may decide to laser engrave any of the following gift types:

Fine jewellery or watches

Glassware or table settings

Party favours, such as keychains or bottle openers

These engravings add a personal touch to otherwise ordinary gifts.

4. Medical and Electronic Components

Medical and electronic parts require easy and precise identification, especially during high-stress moments. To ensure these parts stay identifiable, many manufacturers choose to mark them using laser engraving.

Reasons to mark these components via engraving include:

Easy legibility, even at small sizes

Lettering that won‘t rub off

Simple mass marking

The laser engraving used on medical and electronic components, especially on small or delicate parts, is often shallower than that used on other items.

5. Signage

Perhaps the most common use of laser engraving is in durable signage. The benefits of engraving maps, directions and other sign contents rather than painting or printing them, are myriad.

Some reasons sites choose engraving over other signage methods include:

Durability, even in difficult environments where the sign may become wet or worn

Increased legibility, due to the depth of the lettering

Rapid production, which is often important in temporary construction areas and similar sites

Most industrial contractors and fabricators who design signage cut individual parts using laser-based equipment. They may even create important manufacturing tools and rely on a computer numerical control system (CNC).

CNC systems use precise, automated cutting and engraving equipment to produce one-off items that fit a specific criteria or to mass produce industrial components.

Consult with a trusted professional metal fabrication team to determine if you need the accuracy and precise detail offered by CNC equipment for your project.

Whether you want to create the perfect, personalised gift or you need a clear, durable way to create signage for your job site, consider laser engraving.

Howweld products are built using a ytterbium-doped fiber optics and offer the same low environmental impact and low maintenance (up to 50,000 working hours).

They can be used on any metal to engrave text, photographs, logos, and markings. The maximum marking area ranges from 65x65mm to 180x180mm depending on the lens. The standard lens offers a 110x110mm working area with a resolution of 20μm.

The machine is small, with a fully accessible working chamber thanks to the absence of closures and hatches. There are two available models with either 10W or 20W of maximum output power. Maneuvering pieces and configuring setups is very fast and easy, however, unlike the Engraver series, the z-axis is not motor driven and must be adjusted manually. To help position the z-axis appropriately, the engraver machine has an innovative and intuitive focusing system with overlapping laser pointers. The engraver can also be equipped with a video camera for optimization of the processing, and for possible remote assistance.

Software is included with these engravers. The software is capable of importing files from commonly-used computer design programs such as svg, dxf, bmp, plt, jpg, dwg, and others. The software makes it easy to perform any job from engraving an image, engraving text on the inside of a ring, engraving a custom design on a bangle, to marking and cutting custom shaped objects.

Additional options that can be included with the LZR Engraver machines include: high precision rotating axis system for rings and bangles, electro-pneumatic feeder for metal sheets, vacuum exhaust system with filters, XY clamp for positioning pieces, and a pneumatic hatch opening system.