Engine mould,Injection mould laser cleaning

Time:2021-11-02

Views:991

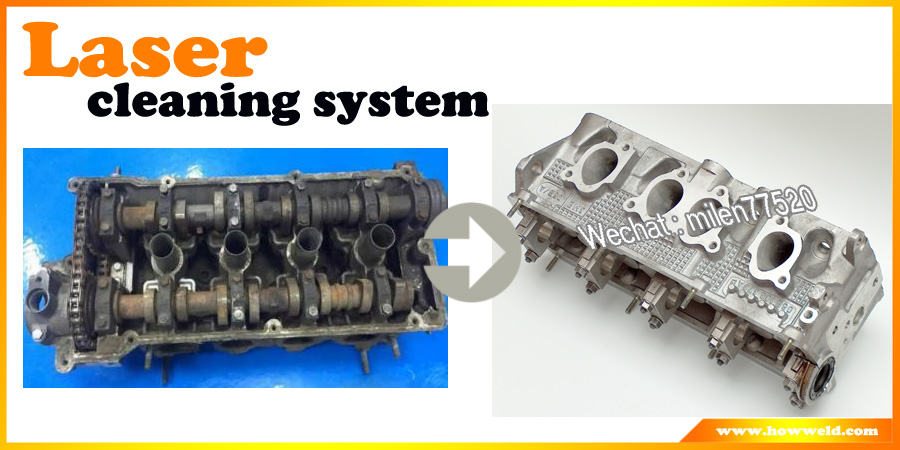

Engine mould,Injection mould laser cleaning

Engine is a machine that can convert other forms of energy into mechanical energy, including internal combustion engine (gasoline engine, etc.), external combustion engine (Stirling engine, steam engine, etc.), motor, etc. For example, internal combustion engines usually convert chemical energy into mechanical energy. The engine is not only applicable to the power generation device, but also refers to the whole machine including the power device (such as gasoline engine and aeroengine). The engine was first born in Britain. Therefore, the concept of engine also comes from English. Its original meaning refers to the "mechanical device generating power".

Injection mold enterprises often worry about the oil stain on the mold, and a good mold is indispensable for the production of a good engine. Only a clean mold can produce a qualified engine. With the progress of production plan, all kinds of oil stains will accumulate around the mold, which will not only damage the service life of the mold, but also greatly affect the qualified rate of finished products. Therefore, it is imperative to remove oil and glue. The cleaning of the mold can better serve the production. The bright and oil-free workpiece can not be without the support of the mold.

There are some disadvantages in the traditional methods of cleaning molds. Looking for a more suitable cleaning method can bring benefits to enterprises. With the development of laser cleaning industry, laser cleaning components also began to be applied in the mold industry. The principle of laser cleaning is to irradiate the workpiece surface with high-frequency and high-energy laser pulse, and the coating layer can instantly absorb the focused laser energy, so that the oil stain, rust spot or coating on the surface can evaporate or peel off instantly, so as to effectively remove the surface attachment or surface coating at high speed. The laser pulse with very short action time will not damage the metal substrate under appropriate parameters.

Advantages of laser cleaning:

1. Green cleaning: completely solve the environmental pollution caused by chemical cleaning;

2. No damage cleaning: no grinding, non-contact, no damage to the substrate, only remove the surface pollutants;

3. Low cost cleaning: no consumables, only very little power consumption during operation;

4. Precision cleaning: precision cleaning can be carried out in the designated area;

5. Improve the working environment: reduce manpower and solve the problem of difficult employment;

6. Automatic cleaning: supporting automatic equipment, easy to detect and control, and complete automatic cleaning.

The above content comes from Howweld.A laser equipment manufacturer with suitable price in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com

The above content comes from Howweld.A laser equipment manufacturer with suitable price in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com