How to solve cracks and air hole in laser cladding coatings

Time:2024-10-22

Views:205

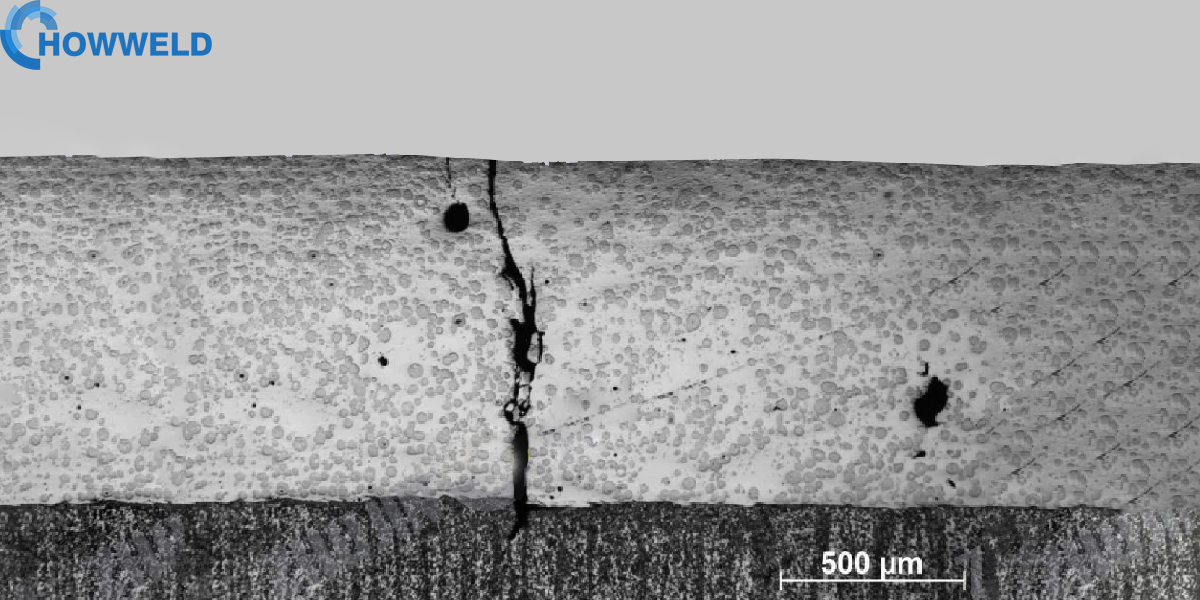

How to solve cracks and air hole in laser cladding coatings

01 Defect formation mechanism

The forming process of the laser-based cladding method includes the interaction between metal powder and laser, heat transfer and loss between the molten pool and the interface, and the flow and solidification of the molten metal. These complex physical and chemical phenomena, coupled with the uncertainty of process control, can easily induce defects in the cladding layer such as pores and cracks.

02 Causes of pore formation and how to avoid them

The process parameters such as laser power and scanning speed in the processing technology directly affect the movement characteristics of the melt thermal fluid in the molten pool. The material properties such as alloy composition, thermophysical parameters, moisture, and untreated surface contamination of the substrate have an indirect effect on the heat and mass transfer process in the molten pool, thereby changing the flow characteristics and temperature gradient distribution in the molten pool. Therefore, exploring reasonable cladding materials and optimal cladding process parameters is still a research hotspot in the field of defect control of laser cladding layers.

03 Causes of crack formation and how to avoid it

Cracks in the cladding layer are defects caused by the combined action of mechanical and metallurgical factors. Under different cladding conditions, the causes, stages and locations of crack formation are different. From the mechanical perspective of induced crack initiation, thermal stress will be induced in the cladding layer under the interaction of laser, powder and substrate. When the tensile stress accumulated locally in the cladding layer exceeds the grain boundary strength of the cladding layer, cracks will initiate from here and expand along the weak position inside the material. In the laser cladding process, there will be accumulation and coupling of various types of complex stresses such as thermal stress, tissue stress, solidification shrinkage stress, etc., which is also the main mechanical source of crack initiation in the cladding layer.

Common defects and solutions in laser cladding coatings

Air hole and crackle cracks

Shenzhen howweld company

Web: www.howweld.com

Contact: info@howweld.com