How to use pulse enhancement technology in laser perforation process

Time:2021-11-12

Views:969

How to use pulse enhancement technology in laser perforation process

For laser cutting, howweld has this kind of machine,can cut most of metal sheets.except that in a few cases it starts from the edge of the plate, in the initial stage, it is generally necessary to pierce a small hole on the plate with the laser, and then start cutting from the small hole. In thick plate cutting, poor perforation is easy to cause poor cutting and processing.

At present, there are basically two perforation methods

One,Pulse perforation

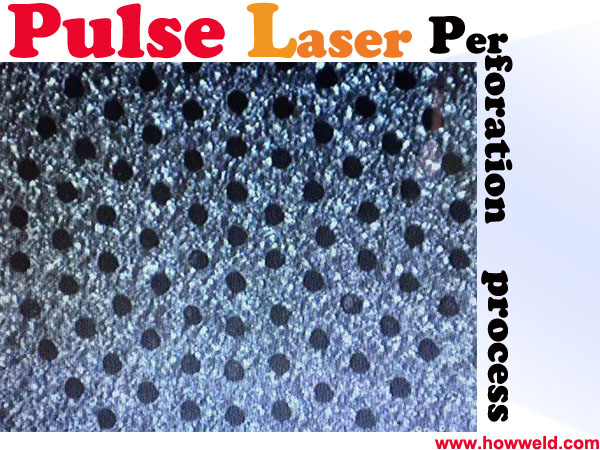

The principle of pulse perforation is to melt or vaporize a small amount of materials by pulsed laser with high peak power. Usually, air or nitrogen is used as auxiliary gas. Each pulse laser will produce a small particle jet and gradually penetrate until penetrating the plate, so the perforation time of thick plate is long.

Two,Blasting perforation

The working principle of blasting perforation is that the material forms a pit in the center after being irradiated by continuous laser, and then the molten material is quickly removed by the air flow coaxial with the laser beam to form a hole.

The size of the hole is related to the thickness of the plate. The average diameter of the blasting hole is usually half of the thickness of the plate. For the blasting perforation of thicker plates, the hole diameter will be large and out of round, so the blasting perforation usually needs to be carried out on the waste area.

The size of the hole is related to the thickness of the plate. The average diameter of the blasting hole is usually half of the thickness of the plate. For the blasting perforation of thicker plates, the hole diameter will be large and out of round, so the blasting perforation usually needs to be carried out on the waste area.

Compare the two perforation methods: the perforation quality of pulse perforation is better than blasting perforation, but the cost of pulse perforation is higher due to the long perforation time. In order to reduce the cost of pulse perforation and improve the perforation efficiency, the continuous high-power fiber laser of enhanced pulse technology: by optimizing the laser output, the pulse peak power far exceeding the rated average output power is provided.

Through the carbon steel and stainless steel perforation test of 2000W conventional pulse perforation and enhanced pulse perforation.

.jpg)

.jpg)

The specific data are as follows:

.jpg)

.jpg)

The specific data are as follows:

It can be seen that the average perforation efficiency of stainless steel plates with a thickness of more than 5mm is increased by 55%, and that of carbon steel plates with a thickness of more than 10mm is increased by 80%.

For high power fiber laser, by increasing the peak power of pulse, not only the perforation time can be shortened and the perforation efficiency can be improved, but also the diameter of upper and lower holes, slag deposition and heat affected zone are small.

.jpg)

.jpg)