Laser cutting processing enters the era of 20000 watts power

Time:2021-08-16

Views:1095

Laser processing enters the era of 20000 watts

Following the opening of the first year of 10,000-watt laser processing in 2019, now it has entered the era of 20kW laser processing. Fiber lasers are developing in the direction of higher power, higher photoelectric conversion efficiency, higher processing efficiency, and lower operating costs. Laser manufacturers are actively introducing higher power products. The technical route based on 976nm high-efficiency is expected to become the mainstream route of the 10,000-watt laser. With the deepening of new infrastructure, medium and heavy plate metal processing is expected to have huge potential in the future. In the application of 10,000-watt laser, China Laser has the opportunity to achieve corners. Overtaking, realizing part of the technology catching up with Western developed countries and surpassing cost-effective products in lasers and laser processing equipment.

In the first half of 2020, the new crown epidemic swept China. Fortunately, the epidemic has been effectively controlled. In April 2020, the central government launched a new infrastructure policy to drive the rapid recovery of the domestic economy. At present, some commercial and industrial plants use steel structures for efficient and convenient construction. This kind of steel processing promotes light processing into a new stage of higher power and higher efficiency. Because 20kW has unique advantages in the above-mentioned laser processing of medium and thick plates, it has caused a wave of 20kW laser processing in the market.

Fiber laser cutting machine cutting for stainless steel,aluminium,copper,titanium materials.Howweld.

The application of fiber lasers in industry has gone through three stages. In 2012 and before, the main industrial application was pulsed fiber lasers for 10-watt marking. At that time, the price of laser marking machines was more than 100,000 yuan or even higher; -In 2019, kW-level fiber lasers will be applied in the domestic large-scale laser cutting of thin plates, mainly to replace part of the punching machine; starting in 2019, light source manufacturers and high-power laser equipment manufacturers have begun to promote 10,000-watt lasers and corresponding laser cutting equipment, and In 2020, the industrial application of 10,000 watts will be further increased to the industrial application stage of 20kW fiber lasers.

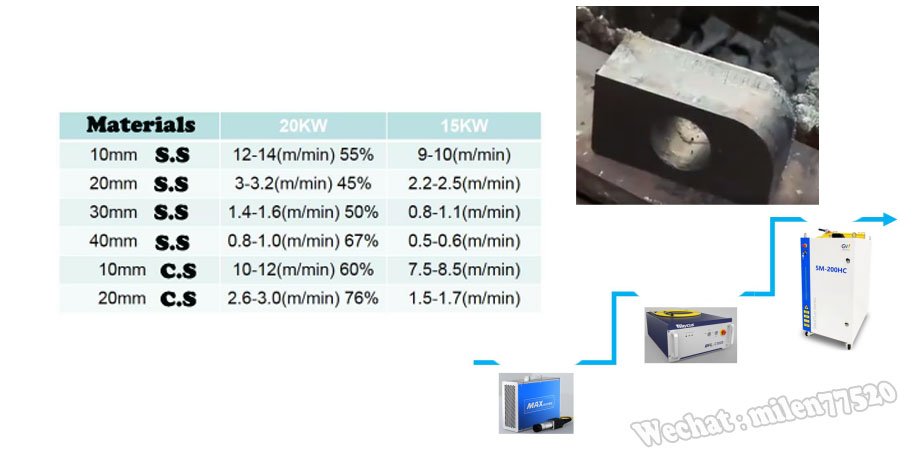

In the past few years, the power of lasers used in industrial applications has continued to increase, from the initial 200W, 500W, 1kW, 2kW, 3kW to the current 6kW, 12kW and even some customers have begun to use 15kW, 20kW. Within a certain range, the laser processing efficiency generally shows a certain non-linear increase with the increase of power. Compared with the 15kW equipment, the released 20kW laser cutting equipment has an average processing efficiency increase of more than 50%, but the power only increases by 33%, showing a random increase. With the increase in power, the efficiency-to-power improvement ratio of the equipment is greater than 1, as follows:

Efficiency ratio = Average (55%, 45%, 50%, 67%, 60%, 76%) + 1 = 1.58

Power ratio = 20000W/15000W = 1.33

Efficiency power ratio = efficiency ratio / power ratio = 1.58/1.33 = 1.18

This means that if the price increases linearly with the increase in power, the higher the power of the product, the higher the processing efficiency per unit price, which will help laser manufacturers continue to increase the laser power until the above-mentioned power efficiency The ratio is less than 1, of course, the actual market power is also restricted by the energy density of the laser (such as the output core diameter of a 20kW laser corresponding to 100um: the energy density is 20kW/(π50um2)) and the load bearing of the industrial power grid.

With the continuous advancement of laser technology and industrial chain, laser processing has gradually entered the 20kW era. Fiber lasers are developing in the direction of higher power, higher photoelectric conversion efficiency, higher processing efficiency, and lower operating costs. Fiber lasers at home and abroad Manufacturers are actively launching higher power products. The technical route based on 976nm high-efficiency is expected to become the mainstream route of 10,000 watt lasers. With the deepening of new infrastructure, medium and heavy plate metal processing is expected to have huge potential in the future. The application of 10,000 watt lasers In the past, China Laser has the opportunity to achieve overtaking in corners, and in lasers and laser processing equipment, it can achieve some of the technology catching up with Western developed countries and the surpassing of cost-effective products.

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com