Laser welding of dissimilar metals,Play super ability

Time:2021-12-26

Views:1000

There are millions of types of metal products, and metal welding is always inseparable from laser welding. With the continuous advancement of technology, laser welding is also commonly used in metal welding, as well as in different types of metal welding.

Metal welding requires firmness after welding, welding penetration, smooth welding bead, beautiful welding, and no polishing. Therefore, laser welding will be more and more commonly used in products, and it will become easier and easier for products to meet laser welding.

With the continuous advancement of science and technology, new structures and new equipment are emerging in endlessly; new materials and new processes are increasingly used, and higher requirements are put forward for the performance of construction machinery components, such as strength, hardness, conductivity, and wear resistance. , Corrosion resistance, low temperature toughness, high temperature durability, etc.

The dissimilar metal composite parts manufactured by the welding method can not only make full use of the excellent performance of each constituent material, but also greatly reduce the production cost and significantly increase the efficiency. Therefore, they are used in automobile manufacturing, electronic appliances, new energy, aerospace and other industries. It has a wide range of applications.Howweld company can customized many kinds laser welding machine for different industries.

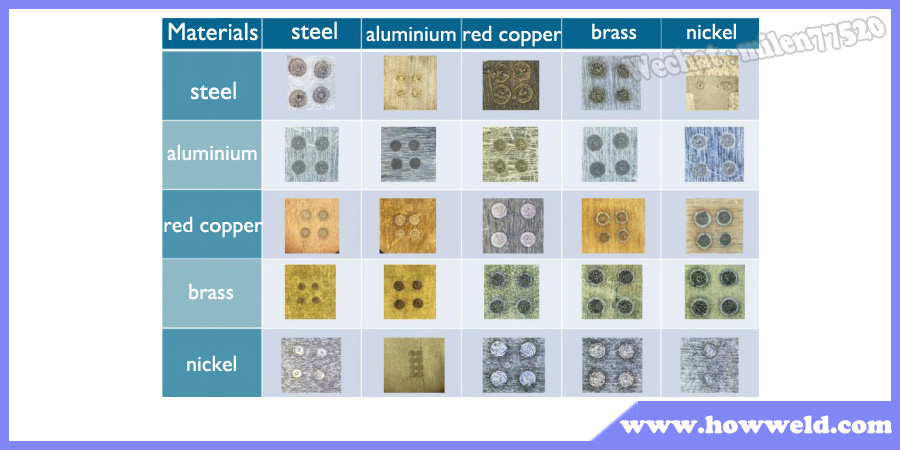

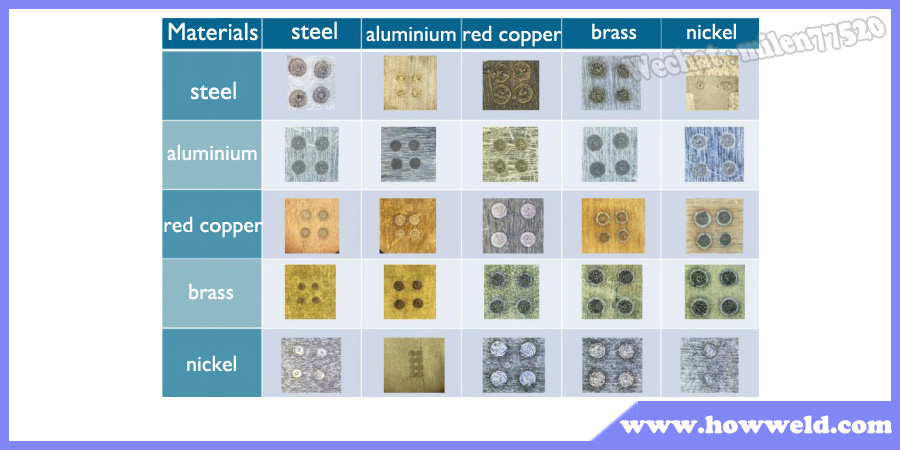

Welding of dissimilar metal materials

1. Welding laser: MOPA 70W-200W, the thicker the metal material, the higher the reflectivity of the material, and the higher the laser power required;

2. Welding method: According to the shape of the welding area, you can choose spiral spot welding or jitter wire welding;

3. Welding configuration: galvanometer scanning welding. Due to the high welding laser power, it is recommended to use fused silica or composite focus field lens to prevent welding instability caused by thermal lens problems;

4. Welding parameters: medium and small pulse width, high frequency, medium and low speed, can be welded firmly, and the welding surface is flat and smooth.

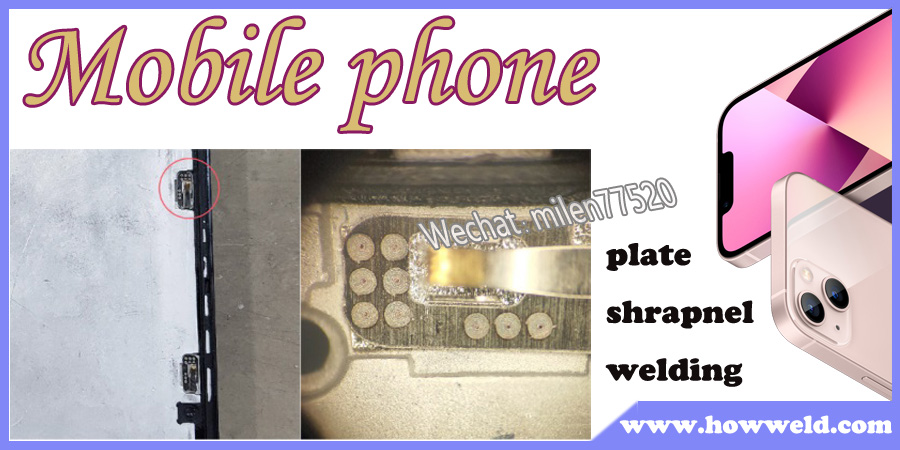

Laser welding can greatly improve the production level and quality of internal components of electronic products. In mobile phones, laser welding is used in many places, such as mobile phone midplane shrapnel, antenna shrapnel, camera module shrapnel welding, etc., laser welding is used to weld metal shrapnel In the conductive position, it can effectively prevent oxidation and corrosion without affecting the conductivity. The material of the shrapnel is generally nickel-plated copper, gold-plated aluminum, copper-plated steel, gold-plated steel, etc., and the material of the mobile phone case is generally aluminum or aluminum-magnesium alloy .

Using MOPA laser to weld mobile phone shrapnel, the welding spot is beautiful, and the welding firmness is stronger.

Battery industry

The new energy industry has developed rapidly in recent years. Among them, lithium batteries and power battery connectors can be well applied to pulse laser welding. MOPA lasers are used to weld metal connectors of different properties to the battery electrodes, so that they are perfectly combined with existing strength. It does not affect the conductivity. The material of the connecting piece is generally aluminum, nickel, nickel-plated copper, etc., and most of the battery electrode material is aluminum or copper.

Using MOPA laser to weld the battery connecting piece, the heat-affected zone of the solder joint is small and beautiful, and the welding penetration is deeper than that of the traditional laser.