New Development Direction of Laser Welding Technology 2023 to 2026

Time:2023-10-20

Views:510

New Development Direction of Laser Welding Technology

Laser welding technology is a comprehensive technology that integrates laser technology, welding technology, automation technology, material technology, mechanical manufacturing technology, and product design.

Ultimately, it is reflected as both a complete set of specialized equipment and a matching process. As an important component of advanced manufacturing technology, laser welding technology has broad application prospects in the future aviation manufacturing industry. The development direction of laser welding technology mainly includes the following aspects:

Ultimately, it is reflected as both a complete set of specialized equipment and a matching process. As an important component of advanced manufacturing technology, laser welding technology has broad application prospects in the future aviation manufacturing industry. The development direction of laser welding technology mainly includes the following aspects:

1. Laser welding with filler wire

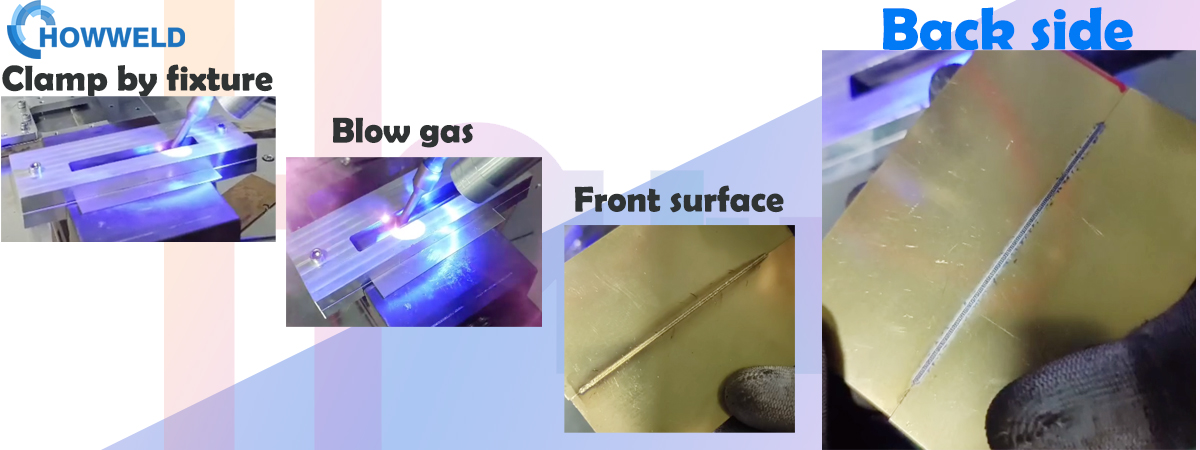

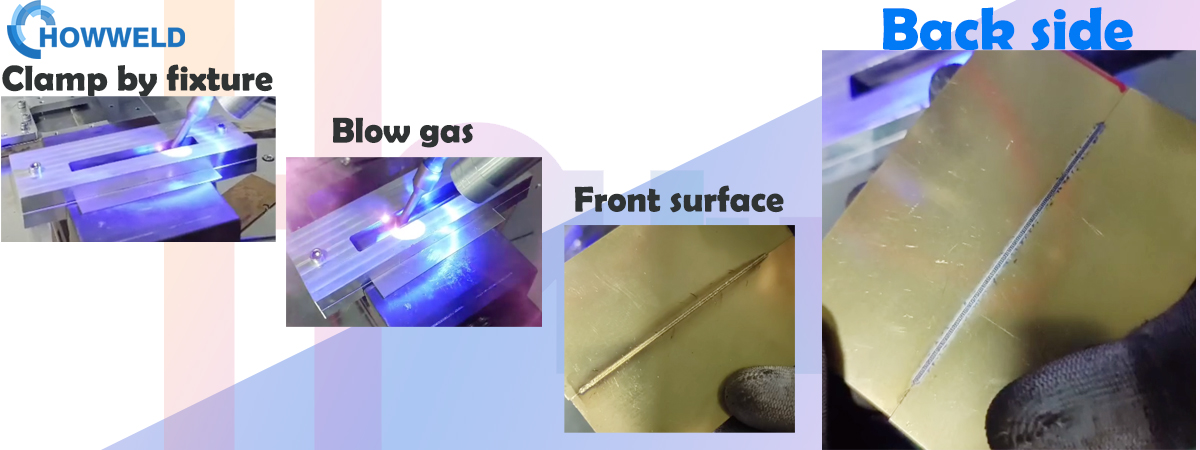

Laser welding generally does not fill the welding wire, but it has high requirements for the assembly gap of welding parts, which is sometimes difficult to ensure in actual production, limiting its application range.

The use of wire filling laser welding can greatly reduce the requirements for assembly gaps. For example, for aluminum alloy plates with a thickness of 2mm, if filling welding wires are not used, the gap between the plates must be zero in order to achieve good forming φ 1.6mm welding wire as filler metal can ensure good formation of the weld even if the gap increases to 1.0mm. In addition, the filler wire can also be adjusted for chemical composition or used for multi-layer welding of thick plates.

The use of wire filling laser welding can greatly reduce the requirements for assembly gaps. For example, for aluminum alloy plates with a thickness of 2mm, if filling welding wires are not used, the gap between the plates must be zero in order to achieve good forming φ 1.6mm welding wire as filler metal can ensure good formation of the weld even if the gap increases to 1.0mm. In addition, the filler wire can also be adjusted for chemical composition or used for multi-layer welding of thick plates.

2. Beam rotation laser welding

The method of rotating the laser beam for welding can also greatly reduce the requirements for welding assembly and beam alignment. For example, when butting a 2mm thick high-strength alloy steel plate, the allowable gap for butt joint assembly increases from 0.14mm to 0.25mm; For 4mm thick plates, it increases from 0.23mm to 0.30mm.

The allowable alignment error between the beam center and the weld center has increased from 0.25mm to 0.5mm.

The allowable alignment error between the beam center and the weld center has increased from 0.25mm to 0.5mm.

3. Online detection and control of laser welding quality

The use of light, sound, and charge signals from plasma to detect laser welding processes has become a hot research topic both domestically and internationally in recent years, with a few research achievements reaching the level of closed-loop control.

The sensors and their functions used in the laser welding quality detection and control system are briefly introduced as follows:

(1) Plasma monitoring sensor

1) Plasma optical sensor (PS): Its function is to collect the characteristic light - ultraviolet light signal of the plasma.

2) Plasma Charge Sensor (PCS): Using a nozzle as a probe to detect the potential difference formed between the nozzle and the workpiece due to the uneven diffusion of plasma charged particles (positive ions, electrons).

(2) System functions

1) Identify which method the laser welding process belongs to. Stable deep penetration welding process, with plasma, strong PS and PCS signals;

Stable thermal conductivity welding process, without generating plasma, with PS and PCS signals almost equal to zero;

The mode is unstable during the welding process, where the plasma intermittently generates and disappears, and correspondingly, the PS and PCS signals intermittently rise and fall.

2) Diagnose whether the laser power transmitted to the welding area is normal, and when other parameters are constant, the strength of PS and PCS signals corresponds to the magnitude of the power incident on the welding area.

Therefore, monitoring the PS and PCS signals can determine whether the light guide system is functioning properly and whether the power in the welding area has fluctuated.

Therefore, monitoring the PS and PCS signals can determine whether the light guide system is functioning properly and whether the power in the welding area has fluctuated.

3) Automatic tracking of nozzle height. The PCS signal decreases as the distance between the nozzle and the workpiece increases.

Using this law for closed-loop control can ensure that the distance between the nozzle and the workpiece remains unchanged, achieving automatic tracking in the height direction.

Using this law for closed-loop control can ensure that the distance between the nozzle and the workpiece remains unchanged, achieving automatic tracking in the height direction.

4) Automatic optimization of focus position and closed-loop control. Within the range of deep penetration welding, when the beam focus position fluctuates, the plasma optical signal received by the PS also changes accordingly, with the PS signal being the smallest at the optimal focus position (at which point the hole is the deepest).

Based on the discovered pattern, automatic optimization and closed-loop control of the focus position can be achieved, resulting in a fluctuation of less than 0.2mm in the focus position and less than 0.05mm in the melting depth.

Based on the discovered pattern, automatic optimization and closed-loop control of the focus position can be achieved, resulting in a fluctuation of less than 0.2mm in the focus position and less than 0.05mm in the melting depth.

Summary:

While laser welding technology is widely used, people are also continuously conducting in-depth research on it. In response to its shortcomings, the heating performance of other heat sources is utilized to improve the heating of the workpiece by laser.

On the basis of maintaining the advantages of laser heating, laser and other heat sources are combined for composite heat source welding, mainly including laser and arc, laser and plasma arc Laser and induction heat source composite welding, as well as dual laser beam welding, etc.

On the basis of maintaining the advantages of laser heating, laser and other heat sources are combined for composite heat source welding, mainly including laser and arc, laser and plasma arc Laser and induction heat source composite welding, as well as dual laser beam welding, etc.

Composite welding can increase welding penetration, improve joint performance, reduce equipment costs, and increase welding speed and productivity.

In short, laser welding has high production efficiency, stable and reliable processing quality, and good economic and social benefits. In the era of endless and constantly updated new equipment, materials, technologies, and processes, producers not only need to understand the characteristics, advantages, and requirements of laser welding, but also recognize many innovations and future trends in this field.

Only in this way can they grasp the trend of technology popularity and always stay at the forefront of the times.

The above content comes from Howweld. A laser equipment manufacturer with suitable price in China, persistently promote the application of laser equipment in various industries, to provide customers with the most suitable solution. Welcome to inquire, visit and testing samples. Email: info@howweld.com

Only in this way can they grasp the trend of technology popularity and always stay at the forefront of the times.

The above content comes from Howweld. A laser equipment manufacturer with suitable price in China, persistently promote the application of laser equipment in various industries, to provide customers with the most suitable solution. Welcome to inquire, visit and testing samples. Email: info@howweld.com