Solutions to five defects in laser welding

Time:2021-09-14

Views:1058

Technical analysis: Solutions to five defects in laser welding

With the advantages of high efficiency, high precision, good effect and easy automation integration, laser welding is widely used in various industries and plays an important role in industrial production and manufacturing, including military, medical, aerospace, 3C auto parts, mechanical sheet metal, new energy, bathroom hardware and other industries.

However, any processing method without mastering its principle and process will produce certain defects or defective products, and laser welding is no exception. Only by understanding these defects well and learning how to avoid them can we give better play to the value of laser welding and process products with exquisite appearance and high quality.

Howweld team welding application engineer has summarized some solutions to common welding defects through long-term experience accumulation, which can be used as a reference for colleagues in the industry!

Howweld team welding application engineer has summarized some solutions to common welding defects through long-term experience accumulation, which can be used as a reference for colleagues in the industry!

1、 Crack

The cracks produced in laser continuous welding are mainly thermal cracks, such as crystallization cracks and liquefaction cracks. The main reason is that the weld produces large shrinkage force before complete solidification. Wire filling, preheating and other measures can reduce or eliminate the cracks.

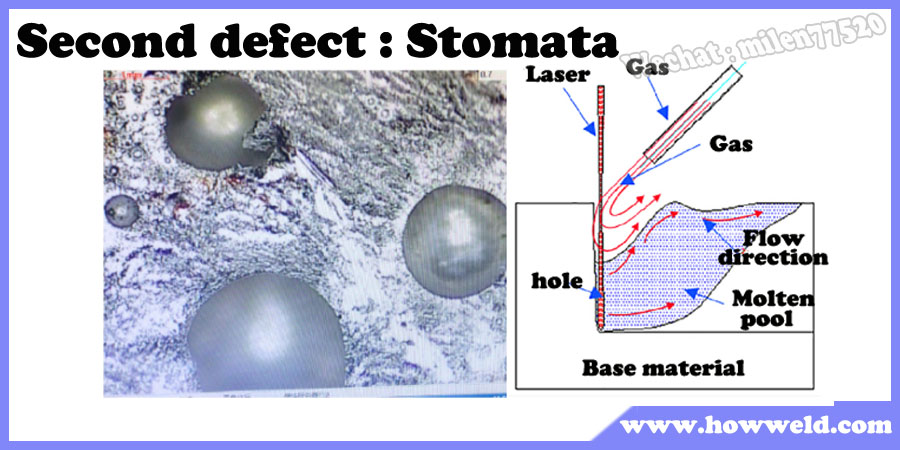

2、 Stomata

Blowholes are easy defects in laser welding. The molten pool of laser welding is deep and narrow, and the cooling speed is very fast. The gas generated in the liquid molten pool does not have enough time to escape, which is easy to lead to the formation of pores. However, laser welding cools quickly, and the porosity is generally smaller than that of traditional fusion welding. Cleaning the workpiece surface before welding can reduce the tendency of pores, and the direction of blowing will also affect the generation of pores.

3、 Splash

The spatter produced by laser welding will seriously affect the weld surface quality and pollute and damage the lens. Spatter is directly related to power density. Properly reducing welding energy can reduce spatter. If the penetration is insufficient, the welding speed can be reduced.

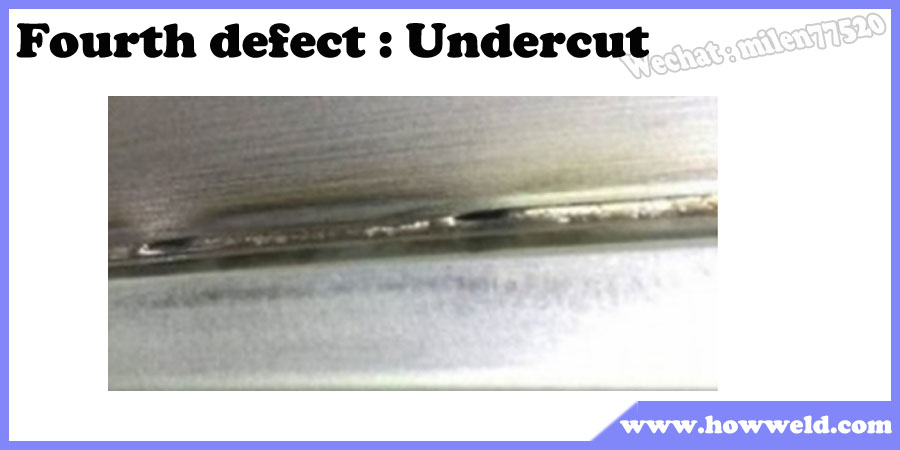

4、 Undercut

If the welding speed is too fast, the liquid metal pointing to the weld center at the back of the small hole will not have time to redistribute, and it will solidify on both sides of the weld to form undercut. The joint assembly gap is too large, the caulking molten metal is reduced, and undercut is easy to occur. At the end of laser welding, if the energy decreases too fast, the small hole is easy to collapse, resulting in local undercut. Matching the power and speed can well solve the generation of undercut.

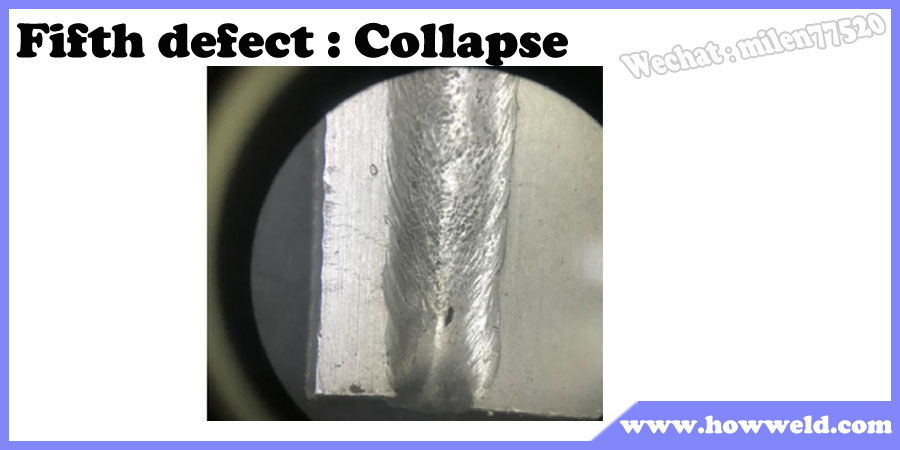

5、 Collapse

If the welding speed is slow, the molten pool is large and wide, the amount of molten metal increases, and the surface tension is difficult to maintain heavy liquid metal, the weld center will sink and form collapse and pits. At this time, it is necessary to appropriately reduce the energy density to avoid the collapse of the molten pool.

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com