Brief introduction:

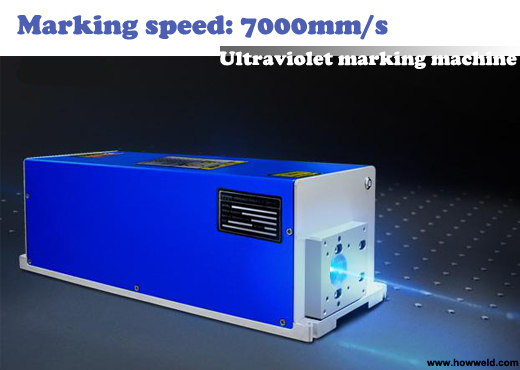

UV laser marking machine.Obviously,the machine is equipped with an UV laser source.It is developed with a 355nm UV laser.Similar to the fiber laser marking machine,it uses a laser beam to permanently mark the surface of various substances.The effect of marking is to directly break the molecular chain of substances through short wavelength laser,so as to show the patterns and words to be etched.(Different from the evaporation of surface material produced by long wave laser to expose deep material)

UV laser marking machine is a series of products of laser marking machine.

Compared with infrared laser, 355 UV focusing spot is very small, which can

reduce the mechanical deformation of materials to a great extent and has little

processing thermal impact.

It is especially suitable for microporous marking.

Application fields such as high-speed division of glass materials and complex

pattern cutting of silicon wafers.

Configuration:

Compared with infrared laser, 355 UV focusing spot is very small, which can

reduce the mechanical deformation of materials to a great extent and has little

processing thermal impact.

It is especially suitable for microporous marking.

Application fields such as high-speed division of glass materials and complex

pattern cutting of silicon wafers.

Configuration:

| Laser source | Ultraviolet laser source |

| Scanning head | High speed scanning galvanometer system |

| Software | EzCAD |

| Computer | Standard computer,win 10 |

| Control card | JCZ card |

Technical specification:

| Laser Power | 3W |

| Laser wavelength | 355nm |

| Frequency | 8~70 KHz |

| Marking range | 100*100mm optical 200,300 |

| Marking speed | 7000 mm/s |

| Power supply | 220V,50Hz |

| Power consumption | 800W |

| Cooling way | Air cooling,or water cooling |

| Weight | 160kg |

Which power machine should choose:

Characteristics:

1. High efficiency in electrical / optical conversion, wind cooling ;

2. Small in size, with high beam output quality, high reliability;

3.The marking speed is 3~12 times of first and second generation of laser markers;

4.No consumable ,8 years service life of the laser source,energy saving;

Applicable materials and industries:

1.used for fields with higher requirements in depth, smoothness and precision;

2.used to engrave metallic and non-metallic materials, for example, stainless steel decorating parts for handsets, clocks, watches, moulds, ICs, handset buttons, bitmap marking etc.

Sample display: