Laser cladding is a process in which a metal coating is applied onto the surface of a part using a laser as the heat source. The process is often used to create a protective coating for increased functionality, as well as restore damaged or worn surfaces.

Laser cladding allows extended life of equipment and machinery in which parts are exposed to corrosion, wear or impact. For example, the construction equipment industry applies this technology to their products to increase wear resistance and keep equipment in service longer.

Repair Process of metal inner wall by laser cladding technology

In practical applications, due to corrosion, high temperature oxidation, friction and wear, the inner surface of the tube parts is often severely damaged, resulting in shortened life and a lot of economic losses in engineering applications.

Therefore, it is very important to perform laser cladding repair on the inner wall surface of the metal tube to make it have higher hardness, better friction and wear resistance, high temperature resistance, pressure resistance, corrosion resistance, etc. realistic meaning. The following describes the repair process of metal inner wall laser cladding technology;

The traditional electroplating coating has shortcomings in performance. More importantly, the electroplating solution has serious pollution to the environment. Today, with the increasing environmental protection requirements, the electroplating industry is gradually being replaced. This refers to a new process that replaces the electroplating industry: laser cladding technology.

Laser cladding is the main alloy of the alloy powder that needs to be melted into the cladding layer without laser. The cladding layer and the base metal are melted in a thin layer to form a metallurgical combination of laser surface repair treatment technology.

Laser cladding is the main alloy of the alloy powder that needs to be melted into the cladding layer without laser. The cladding layer and the base metal are melted in a thin layer to form a metallurgical combination of laser surface repair treatment technology.

The high energy density and high directionality of the laser can be used to treat the inner surface of the tubular material, so that the performance of the inner surface of the tubular workpiece can be improved, especially the hardness, strength, wear resistance, corrosion resistance and high temperature resistance of the inner surface. Thereby increasing the service life of the tubular material.

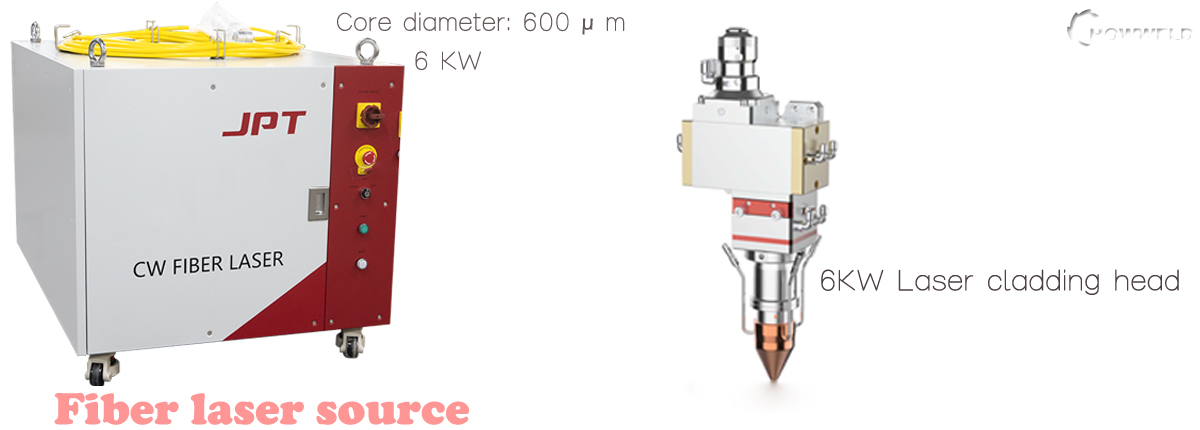

Main configurations:

Main configurations:

| Description | Model |

| Fiber laser source | Continuous type 3000W 6000W |

| Laser cladding head | Circular spot 3mm 4mm |

| Water cooling system | Capacity 12KW |

| Rotating platform | X Y Z Axis 1.5*0.5*0.5 meter |

| Control system | CNC3000 |

| Powder feeder system | Single barrel powder feeder |

| Power supply | 380V, 50Hz |

| X Y Z Rail | Hiwin brand |

| Voltage pressure regulator | 6KW power machine match |

Powder feeder:

We have developed the third generation scraper type accurate powder feeder.

The powder feeder has the advantages of excellent manufacture, good powder feeding continuity, high precision, simple structure (only one independent moving part) and long service life.

It is especially suitable for laser cladding equipment.

| Description | Parameters |

| Powder feeding abount (g/min) | 1~40 |

| Powder feeding accuracy (%) | 1% |

| Capacity of powder storage tank (kg) | 5~50 |

| Particle size (mesh) | 80~350 |

| Powder gas flow (m3/h) | 0.1~0.4 |

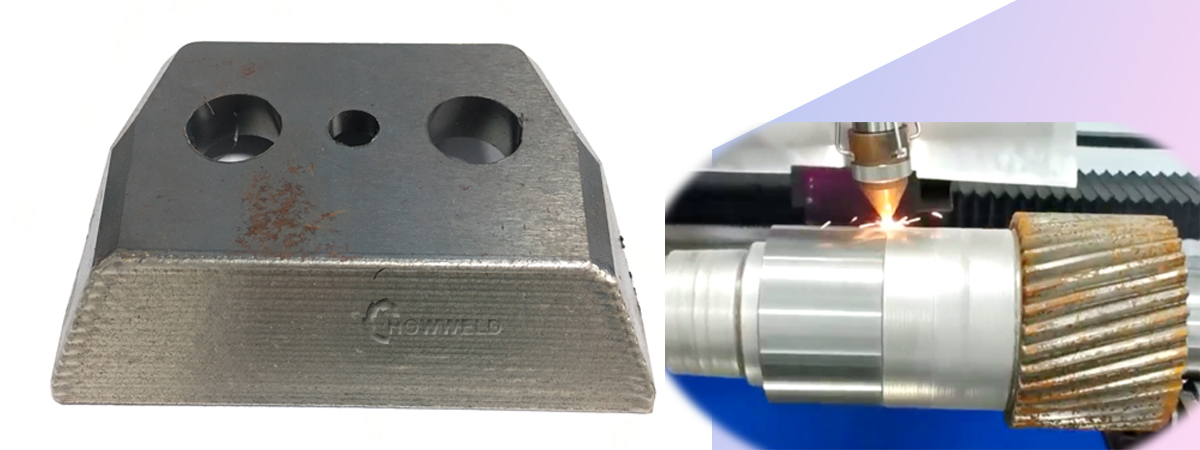

Samples:

Tag: Outer wall cladding with steel powder, copper powder, 2000W Fiber laser, 3000W Fiber laser cladding machine with robot arm