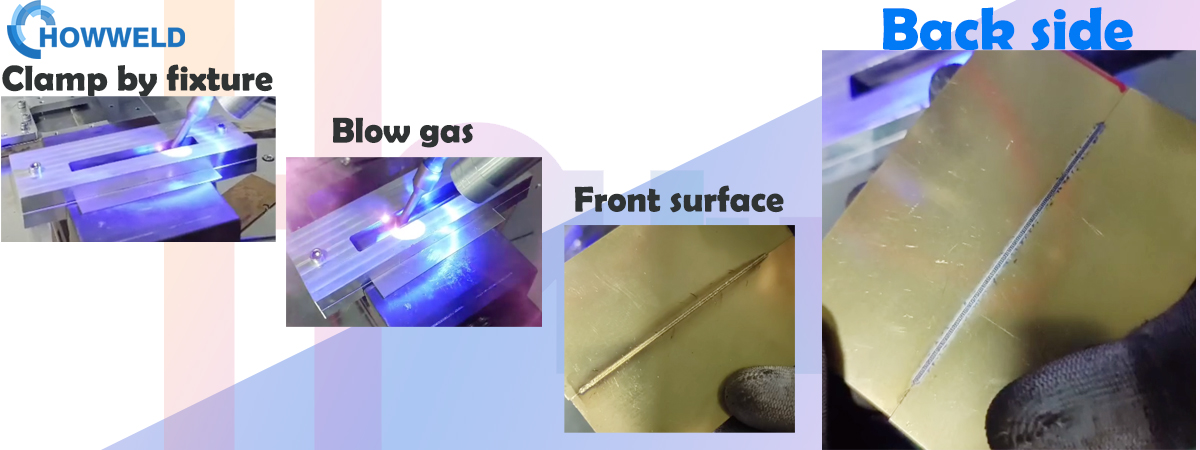

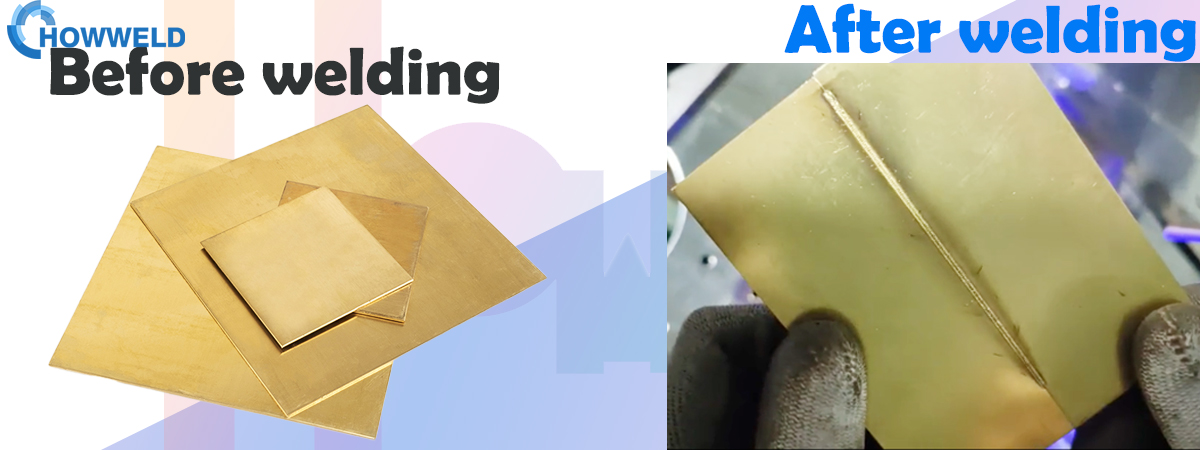

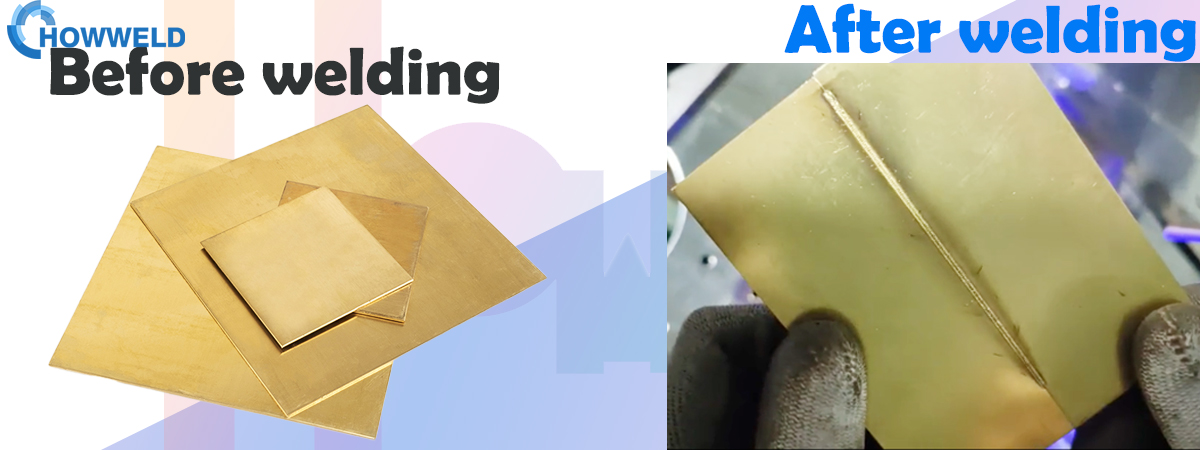

2.0mm copper sheets welded by cnc automatic laser welding machine

Time:2023-04-19

Views:684

Automatic Fiber cnc laser welding system

Laser welding is the use of high-energy laser pulses to locally heat a material in a small area. The energy radiated by the laser is directed through heat transfer to the internal diffusion of the material, melting the material and forming a specific molten pool.

Laser welding is the use of high-energy laser pulses to locally heat a material in a small area. The energy radiated by the laser is directed through heat transfer to the internal diffusion of the material, melting the material and forming a specific molten pool.

It is a kind of welding method, mainly for welding thin-walled materials and parts, which can realize spot welding, butt welding, overlap welding, seal welding, etc., with high depth to width ratio, small weld width, small Heat-affected zone, small deformation, fast welding speed, flat and beautiful welds.

After welding, there is no need for processing or simple processing, the weld quality is high, there are no pores, it can be effectively controlled, the focus point is small, the positioning accuracy is high, and it is easy to achieve automation.

Testing sample: Copper

Test time_Howweld: 2023-4-19

Testing sample: Copper

Machine power: CNC 2KW automatic welding. Raycus laser with table type.

Materials: Copper [Yellow copper]

Thickness: 2mm

Parameters: 20% power usage. [400w usage power]

Welding spend time: 5 seconds

Welding spend time: 5 seconds

Not recommend to choose manual welding machine, because manual welding unable to achieve uniform speed while welding.

Slow speed, penetrating the base copper cause loss base substrate.

Fast speed, not firm welding. Penetration not easy to control by handheld welding machine.

This equipment has fast welding speed, small welding spot (the diameter of the spot at the focal point is only 0.3mm), low welding heat, and small thermal deformation.

The light guide system of the product enables efficient and stable laser spot welding through the rapid movement of the galvanometer. According to the different welding materials, the output energy waveform can be set and controlled to achieve a more ideal welding effect.

The welding machine adopts bidirectional control of industrial control machine and imported PLC, which enables the high-speed galvanometer system to be well integrated with the CNC workbench. Compared with traditional stepper motor motion and laser beam path fixed continuous welding methods, the welding efficiency can be improved by more than 10 times, achieving full automation of laser online welding.

For example, using the original hard light path transmission laser welding machine to weld the electrode ears (2 points), the efficiency is 1100 pieces/h; The selection of a scanning laser spot welding machine with a galvanometer can weld electrode ears (multiple points) up to 2000 per hour.

The welding speed reaches 1-20 points/s, effectively shortening the welding time, making it particularly suitable for spot welding of ultra-thin stainless steel circuit board inserts such as mobile phone shielding covers, metal mobile phone or metal capacitor shells, hard drives, micro motors, sensors, etc., especially for the welding of cylindrical battery lugs.

Above content writed by Howweld Team that we provide laser processing equipment with service, provide suitable laser welding, laser cleaning solution. Contact email: info@howweld.com

Welcome to inquire, visit and testing samples. We are looking forward to your presence.

Keywords: cnc laser welding machine, automatic laser welding equipment, fiber cnc laser welding, copper laser welding, fiber laser welding for copper

howweld laser, howweld company, China howweld, cnc laser welding system.