Laser hybrid welding system for thick metal sheets

Time:2022-04-27

Views:948

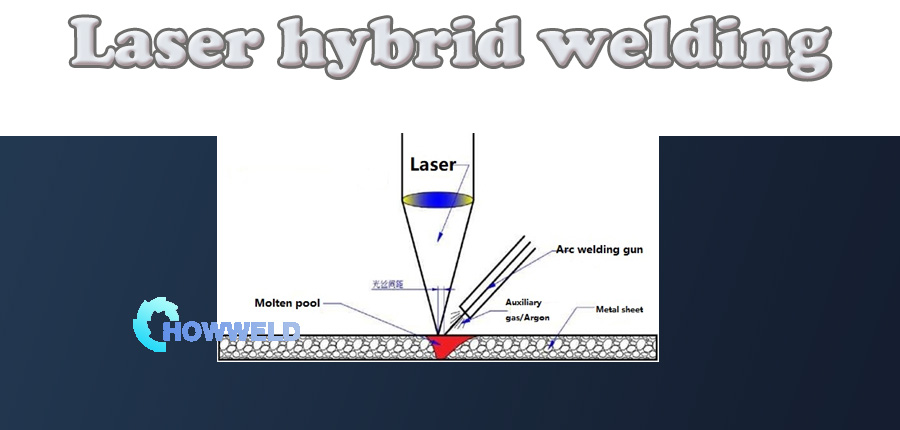

Laser hybrid welding

Laser welding with Arc hybrid welding

1. Laser hybrid welding introduction

In recent years, rail transit, shipbuilding, nuclear power equipment and other industries, medium and large thickness steel plate welding demand is increasing.In addition, the correction of post weld deformation also greatly increases process hour and total cost of ship assembly and manufacturing.

Welding production efficiency and welding quality directly affect the production cycle, cost and hull quality of shipbuilding. Therefore, efficient and high-quality ship welding technology is an important influence to realize the transformation and upgrading of China‘s shipbuilding industry. It is also an important factor to improve the international competitiveness of China‘s shipbuilding enterprises.

In order to meet the requirements of performance, the quality of welded joints has become one of the important links to ensure the quality of bogie frame. Therefore, new welding methods and optimized welding parameters are necessary.

Arc welding is the most commonly used welding method for structural steel plate due to its low cost and mature technology. However, due to the low energy density of arc, the penetration and welding speed of single pass are greatly restricted, so the steel plate with thickness of 25 mm usually needs 4-8 layers of welding.

Laser welding is a promising technique for welding thick metal sheets, which is usually used for achieving full penetration in a single weld pass.

However, among the imperfections that can occur, dropout formation becomes

an increasingly larger problem when the sheets to be welded get thicker.

When the sheets are 15 mm thicker, it is a challenge to suppress and countermeasures to suppress dropouts get less impact. If full penetration is

not achieved, the dropout formation cannot be formed and the melt flows to form better weld caps.

Therefore, a typical method when welding 15 mm and thicker is to use partial penetration from both sides of the joint, thereby achieving full penetration, increasing plate handling complexities and time losses.

Laser with high energy density, laser welding has the ability of high penetration. Laser welding, laser arc hybrid welding and other methods have been applied. On the one hand, it can increase the penetration, on the other hand, it can improve the welding speed, so as to improve the welding efficiency.

Laser arc hybrid welding combines the characteristics of arc welding high fusion width and laser high penetration,with higher potential of single pass penetration of 10-20 mm steel plate. Howweld design this project in 2021.

Laser arc hybrid welding combines the characteristics of arc welding high fusion width and laser high penetration,with higher potential of single pass penetration of 10-20 mm steel plate. Howweld design this project in 2021.

Three main advantages:

1. Improve the energy utilization rate, increase the primary penetration depth and welding speed of the weld;

2. Reduce the requirements of workpiece assembly;

3. Improve weld quality and weld forming.

2. Laser arc hybrid welding can achieve 1 + 1 > 2.

We are thinking this kind of welding possible apply to metal sheets welding.There are many forms of laser arc hybrid welding, including laser MAG / MIG hybrid welding, laser TIG hybrid welding, laser plasma arc hybrid welding, etc,

The main equipments install with CNC laser welding system,high power laser source,Arc welding machine,arc welding gun,wire feeder,high power welding head,chiller.

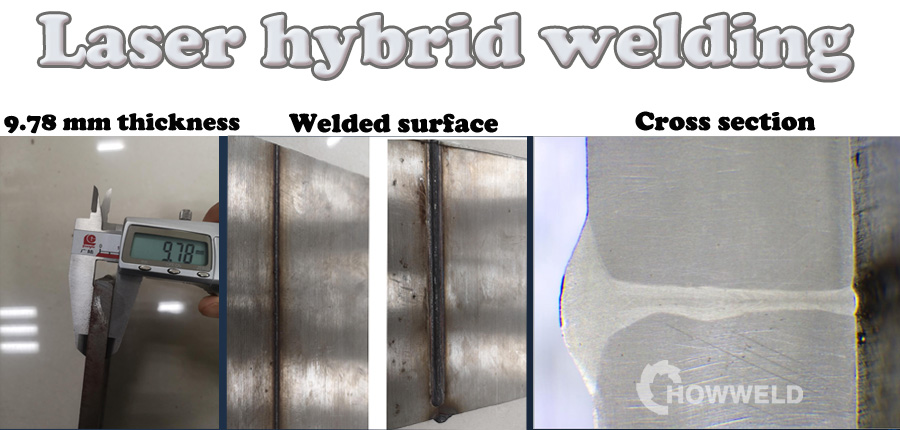

3. 9.78 mm thickness carbon steel welding testing:

1. Both materials tested above have different thicknesses, the front and back sides of the weld are relatively uniform, large depth width ratio of the weld section, and there is no obvious collapse and overlap on the front and back sides of the weld, which can achieve good welding effect.

The above welding parameters are only for reference. Due to the complex process and many factors,it is necessary to strengthen the relevant process research.

2. With the help of laser welding,it can realize one side welding without groove and two side forming of plate with thickness of more than 10 mm, which provides a solution for the welding of large structural parts of medium and heavy plate.

3. Higher power laser with arc hybrid welding process can promote the application of laser, not only limited to laser cutting, we believe that more manufacturers will introduce and put into production in the future.