Pluger product surface add cladding layer hardness hardened layer

Time:2024-11-05

Views:176

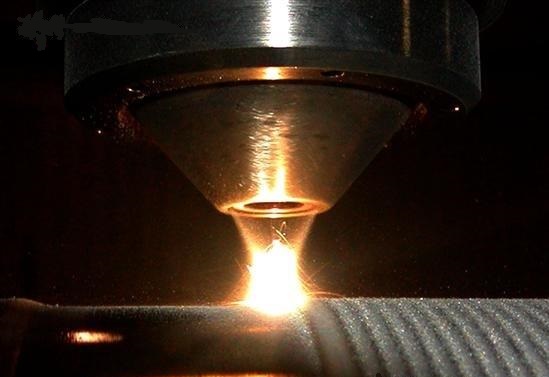

Laser cladding technology refers to the process of placing selected coating materials on the surface of the coated substrate using different filling methods, which are irradiated by laser to melt simultaneously with a thin layer on the substrate surface, and rapidly solidify to form a surface coating with extremely low dilution and metallurgical bonding with the substrate material, thereby significantly improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties of the substrate material surface.

Continuous laser cladding machine test cladding 1mm to 2mm layer, hrc 35

1. Materials

Metal materials: S45C model

Thickness: 1mm on surface

Test time: 2024.8.13

Test company:Howweld

Samples from: Thailand

2. Requirements

Thickness: 1mm on surface, under 2mm

Hardness: 35hrc

3. Test machine

3000W CNC laser cladding machine

AC380V,50Hz

Working temperature: 18~35℃

Raycus laser with rotary type.

Rotary can clamp 500mm diameter

Laser source type: continous type laser

Fiber cable length: 20 meters

4. Parameters of laser

Power: 35%

Cladding speed: 610mm/min

Adjust power: 100%

Laser frequency: 10KHz

Optical core diameter: 600μm

Gas blow while cutting: Nitrogen gas

Before Cladding & After Cladding

Conclusion:

Suitable machine: 3000W CNC laser cladding machine

Laser beam was continous, with water cooling, medium power machine can meet requirements.

Cladding speed can adjust faster when choosen 6000W power

All models laser cladding from market were 2000w 3000w 6000w 8000w

Link: 3000W power laser cladding machine

wear-resisting 200μm 600μm Add 1mm cladding layer on S45C plunger surface to increase hardness to 35hrc.