Break wave aluminized steel cleaning pulse fiber laser cleaning system

Time:2022-03-22

Views:1057

Bakery break wave,the materials is aluminized steel,which used day by day in bakery shop,how will it cleaning by laser?

Teflon coating and epoxy on aluminum and steel surface

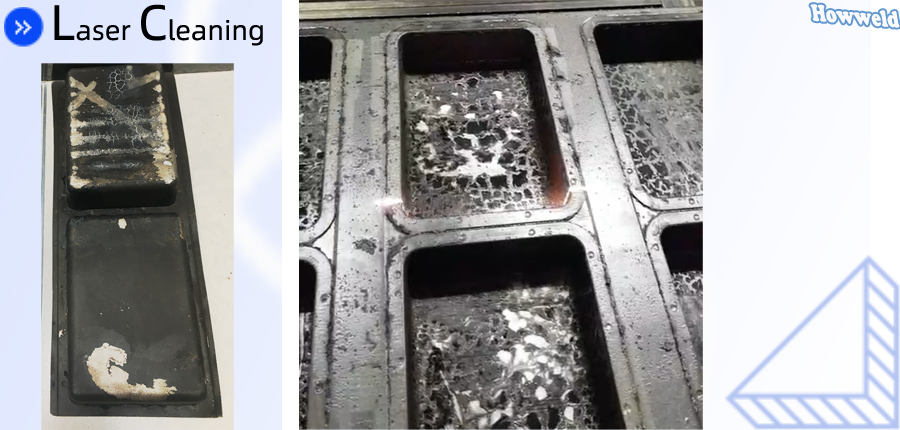

Before cleaning product picture:

Teflon coating and epoxy on aluminum and steel surface

Before cleaning product picture:

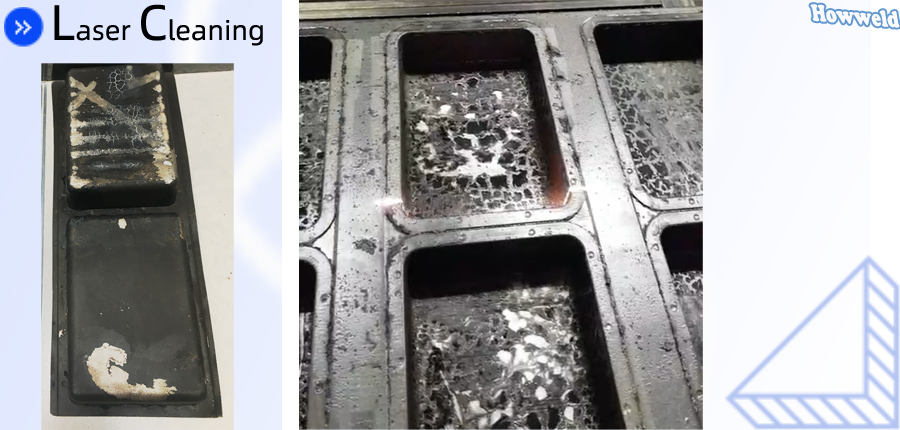

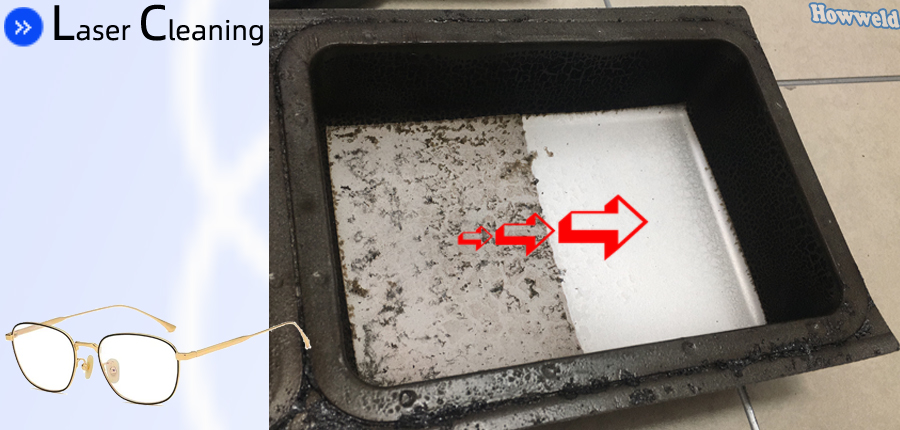

Comparison picture:

Need to remove only teflon,the aluminum on steel should no be damaged by laser.

We test it with below parameters:

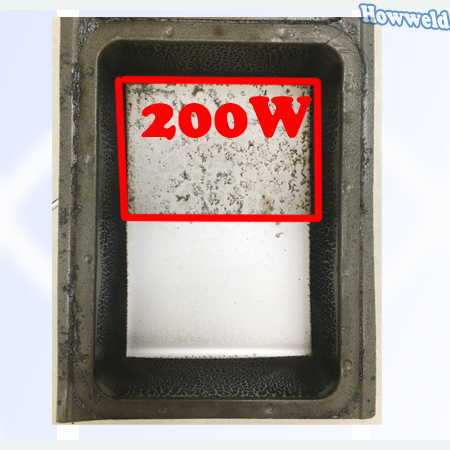

| Machine | Pulse laser cleaning 200w |

| Scanning length | 80mm |

| Scanning width | 60mm |

| Scanning speed | 6000 |

| Scanning number of times | 11 times |

| Time | 360s |

Cleaning effect:

We test it with below parameters:

| Machine | Pulse laser cleaning 300w |

| Scanning length | 80mm |

| Scanning width | 60mm |

| Scanning speed | 6000 |

| Scanning number of times | 5 times |

| Time | 320s |

Cleaning effect:

At this time,we found 200W power was not enough to clean the surface.Even set the 100% used power already.

Cleaning time will be different between both machines.200W power machine need to clean more times,laser scanning head scanning the surface more times so that can remove the teflon coating.

300W power will faster cleaning speed,only scanning 5 times to the surface to get clean surface.