Rust removal fiber laser cleaning machine

Time:2022-07-07

Views:953

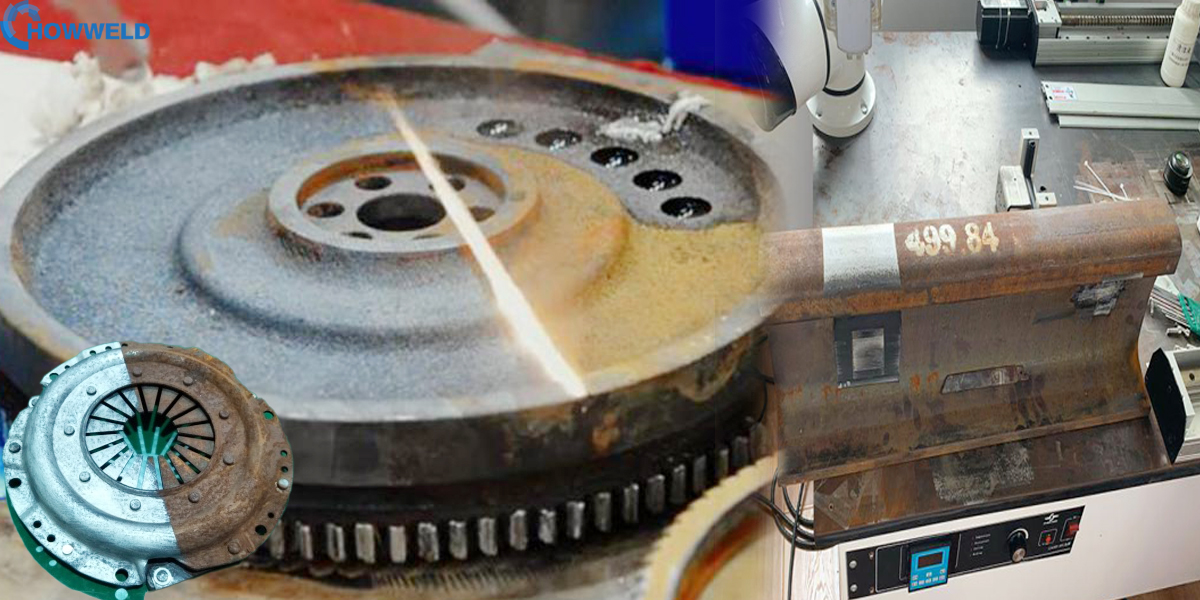

Continuous laser cleaning machine test cleaning: metal rust removal

Brief introdution:

Rusting is a chemical reaction that is essentially the oxidation of metals. The most common rust phenomenon is that iron products have been exposed to the air for a long time and have an oxidation reaction with oxygen, or are eroded by oxygen in water to become oxides. If the rust not removed, the rust is particularly easy to absorb moisture, and the iron plate will rust faster.

Test cleaning:

Test time: 2022.6

Samples from: China

Cleaning requirements: clean surface

Machine power: 1000W laser power, full 100% power, continuous laser beam;

Laser time: 180 seconds one piece;

After cleaning:

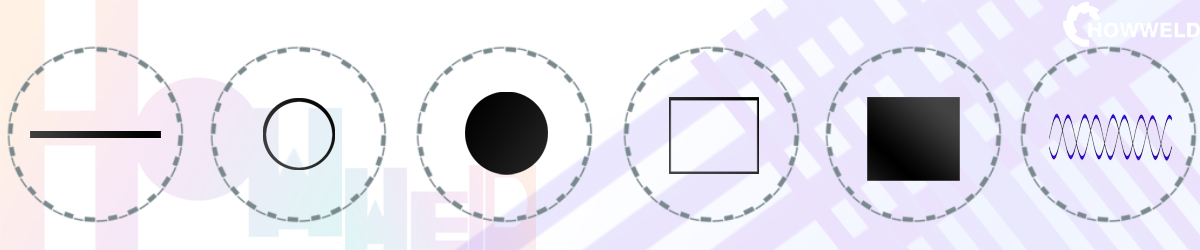

Parameters of laser:

Laser power: 100% full power

Scanning width: 100mm

Scanning speed: 6000

Laser frequency: 2000Hz

Laser pulse: without pulse

Scanning mode: straight line

Scanning pattern can sdjust: line, circle, square, spiral

Scanning pattern can sdjust: line, circle, square, spiral

1. The automotive manufacturing industry has strict requirements for surface treatment of components, and traditional rust removal methods (such as sandblasting and chemical pickling) have the following problems:

Serious environmental pollution

High energy consumption

There is a risk of damage to the substrate

Difficult to achieve automated integration

Laser cleaning technology, as a representative of green manufacturing, is gradually replacing traditional processes and is particularly suitable for the high-precision and high-efficiency cleaning needs of automotive parts.

Advantages of Continuous Fiber Laser Cleaning Technology

2. Technical features

Wavelength: 1064nm (high absorption rate for metal rust layer)

Power range: 2000W-3000W (adjustable, suitable for different cleaning needs)

Beam quality: M ²<1.3 (small focused spot, high energy density)

Pulse frequency: continuous laser

Fiber optic transmission: flexible processing, easy to integrate with automation systems

3. Comparison with traditional craftsmanship

Indicator: Laser Cleaning, Sandblasting, Chemical Cleaning

Environmentally friendly, pollution-free, dust pollution, chemical waste liquid

Low to medium high energy consumption

No possibility of substrate damage

Precision micrometer level millimeter level non-uniformity

Automation is easy, integration is difficult, and challenging

Low to high operating costs

4. Application solutions for automotive parts

Applicable accessory types

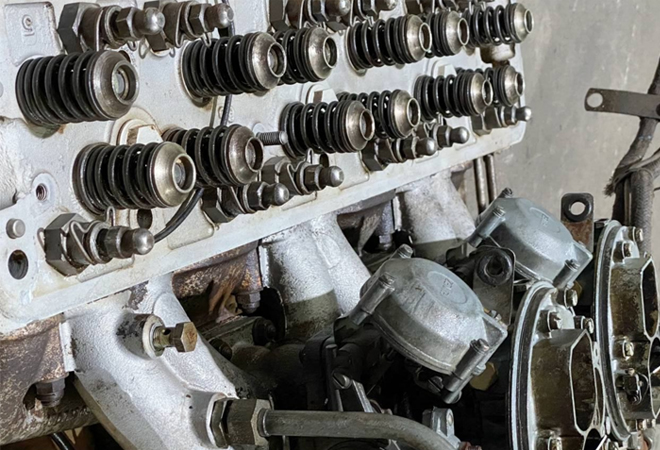

Engine components (cylinder block, crankshaft, etc.)

Transmission system components (gears, bearings, etc.)

Chassis components (suspension components)

Body structural components

Brake system components

5. Surface roughness: Ra<1.6μm

Hot Tags: Wholesale 200w aluminium wheel mold laser cleaning machine, suppliers, manufacturers, factory, customized, wholesale, buy, price, for sale, in stock, laser removal system; 3000W CW laser cleaning machine

Half enclosed Laser Cutting Machine, Laser Marking Machine, 100 Watt Laser cleaner, Pipe rust laser clean, High Power Industrial Laser Cleaning Machine. 1000w pulse laser cleaning machine