Tire Mould rubber mold cleaning pulse fiber laser cleaning system

Time:2021-12-18

Views:1083

Fiber laser cleaning tire mould

Traditional cleaning VS Laser cleaning

Traditional cleaning methods include mechanical cleaning, Laser cleaning technology refers to the process of using

chemical cleaning and ultrasonic cleaning. high-energy laser beam to irradiate the workpiece surface,

Mechanical cleaning method is to remove surface dirt by so that the dirt, rust or coating on the surface can evaporate

scraping, wiping, brushing, sand blasting and other means; or peel off instantly, and effectively remove the attachment

chemical cleaning and ultrasonic cleaning. high-energy laser beam to irradiate the workpiece surface,

Mechanical cleaning method is to remove surface dirt by so that the dirt, rust or coating on the surface can evaporate

scraping, wiping, brushing, sand blasting and other means; or peel off instantly, and effectively remove the attachment

or surface coating on the surface of the cleaning object at

Chemical cleaning method uses organic cleaning agent to high speed,so as to achieve cleaning.

remove surface attachments by spraying, drenching,

soaking or high-frequency vibration. The laser cleaning system can remove rust and pollutants

remove surface attachments by spraying, drenching,

soaking or high-frequency vibration. The laser cleaning system can remove rust and pollutants

efficiently and quickly, and select the removal parts to

Ultrasonic cleaning method is to put the treated parts into realize the automation of cleaning.

the cleaning agent and remove the dirt by using the vibration

effect produced by ultrasonic. Not only the cleanliness is higher than that of chemical

the cleaning agent and remove the dirt by using the vibration

effect produced by ultrasonic. Not only the cleanliness is higher than that of chemical

cleaning process, but also there is almost no damage to

At present, these three cleaning methods still occupy a dominant the object surface.

position in China‘s cleaning market, are not environmentally friendly,

and the accuracy requirements are not enough.

position in China‘s cleaning market, are not environmentally friendly,

and the accuracy requirements are not enough.

However, its application is greatly limited under the requirements

of environmental protection and high precision.

of environmental protection and high precision.

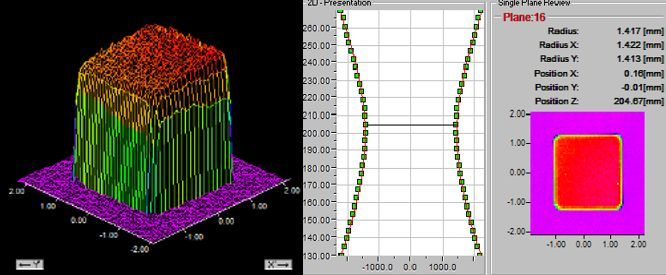

High power pulse laser for surface cleaning

Provide square light spot to greatly improve efficiency

YLPN-50-100-500-R

Wavelength, nm: 1060

Operation mode: pulse

Average power, W: 500

Pulse energy, MJ: 50

Pulse width,: NS 100

Repetition rate: kHz 2-50

Beam quality BPP: < 14

RFL-P300

Wavelength, nm: 1064

Operation mode: pulse

Average power, W: 300

Pulse energy, MJ: 12.5

Pulse width,: NS 120~160

Repetition rate: kHz 30~50

Beam quality BPP: < 5%