Aluminium Welding (MIG And TIG) CNC fiber laser welding Howweld

Time:2021-05-31

Views:1297

Aluminium Welding (MIG And TIG)

Can you weld aluminium? Yes you can, but if you ask any welder which materials are most challenging they’ll probably mention this one. Fortunately, applying a few tips, tricks and guidelines makes aluminium welding even easier to master.

So what will laser welding Equipment or Howweld team [http://www.howweld.com/]suggest? Read on to find out…

But first, a few words on the challenge of working with aluminium. Not surprisingly, it’s aluminium’s inherent characteristics that create the biggest test for welders.

Why Is Welding Aluminium Difficult?

Aluminium is a good thermal conductor that disperses heat quickly, which can easily lead to unwanted workpiece distortion or cracking. Furthermore, aluminium is renowned for its vulnerability to ‘blow through’ – where the metal just melts away under an over-powerful arc. Aluminium also oxidises very quickly when exposed to the atmosphere. This gives aluminium its renowned ability to resist corrosion, but it also means your aluminium workpiece will need thorough cleaning before you strike an arc and weld.

What Welder Do You Use For Aluminium?

Almost exclusively, it will be a MIG or TIG machine. You’ll find a couple of machine suggestions later, but now let’s move on to that guidance. Let’s start with MIG welding aluminium.

MIG Welding Aluminium

Can You Use A MIG Welder On Aluminium?

Absolutely! So here’s some useful advice for MIG welding aluminium. Naturally, it’s a high-level summary.

When choosing electrode tips for MIG welding aluminium, make sure they’re specifically designed (Al-marked) for this versatile material.

Make sure your welding machine and wire-feed mechanism is correct for aluminium welding. This includes fitting a Teflon liner and U-groove rollers. Or by using a dedicated aluminium spool gun to minimise the length of electrode wire being driven. It might also involve – normally only for intensive professional use – using a push-pull MIG torch for super-precise wire delivery. However, do be aware that not all MIG welding machines work with a dedicated aluminium spool gun – look at R-Tech’s MIG 180, PRO MIG 250 and MTS 255 to see some machines that do. By the way, although the R-Tech MTS 450 doesn’t take a spool gun, it has a very good four-roller wire-feed system that can be fitted with U-grooved rollers that grip aluminium wire firmly.

Moving from the welding machine cabinet to the MIG torch, do make sure that your torch is in good condition. If you’re planning lots of aluminium MIG welding, you might consider a larger-sized torch. Why? Because the greater heat generated by welding aluminium can overwhelm a low-capacity torch. With aluminium, it’s always good to have power in hand…

Now think back to how aluminium oxidises, and the different thermal properties of aluminium and those oxides. It’s vital to clean your aluminium workpieces thoroughly before welding. Use a stainless-steel wire brush that’s only used on aluminium, brush in one direction only, and be careful not to work the oxide layer into the material. If the aluminium’s surface is oily, use a good degreaser.

As with all MIG welding, make sure to choose the correct wire for the grade of material (in this case aluminium) that you’re welding.

Due to its thermal properties, aluminium is very prone to distortion. Minimise the risks by tack welding or clamping the joint to prevent movement or distortion as you weld.

If you’re welding particularly thin aluminium, consider using a brass or copper backing plate behind your work. It helps avoid the blow through that aluminium is so susceptible to. Welding with a fast travel speed is another way to prevent blow through – and distortion.

Stop and start as little as you can. To avoid porosity or voids when MIG welding aluminium, weld in one pass wherever possible. Because aluminium’s notoriously cold to start with, it needs to get up to temperature and stay there – hence the importance of that single pass if you want to avoid undesirable cold-lapping.

What Gas Do You Use For MIG Welding Aluminium?

Typically, it’s pure argon run at a gas-flow rate of around 14–16 LPM.

TIG Welding Aluminium

As with the MIG process, remembering and applying a few basic guidelines makes a difference when TIG welding aluminium. Again, choosing the correct TIG welding machine is vital. You’ll need an AC/DC machine with sufficient power to weld the thicknesses of aluminium you’re working with. Machines such as R-Tech’s AC/DC TIG161 and 170EXT exhibit the characteristics of a good TIG machine.

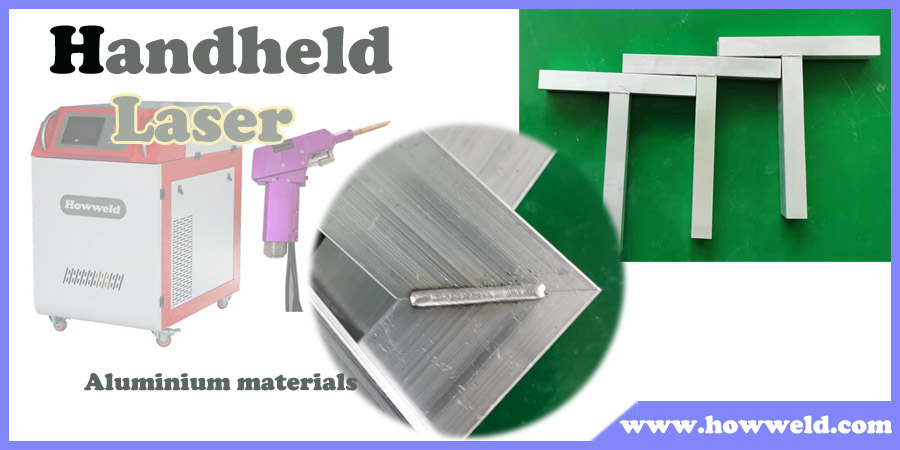

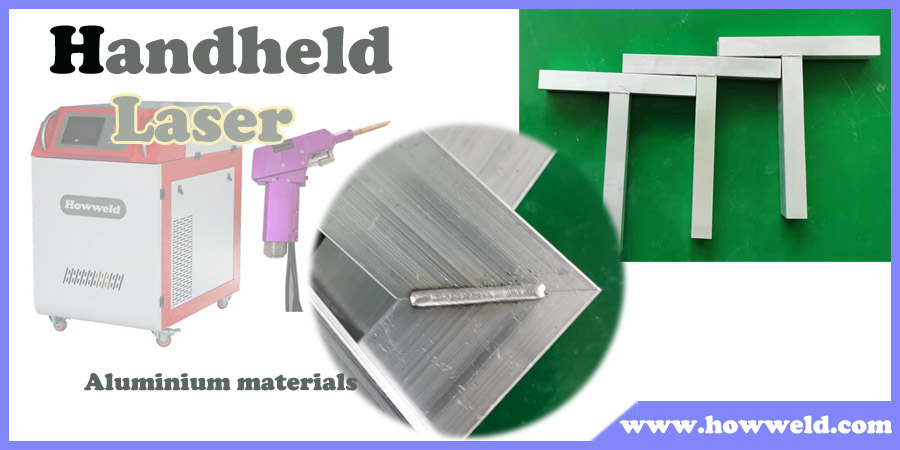

Howweld is a famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.

Welcome to inquire, visit and testing samples.We are looking forward to your presence.Email:info@howweld.com