Aluminum door frame hand-held laser welding smooth surface Aluminum guardrail welder

Time:2024-02-27

Views:736

What should be noted when welding aluminum doors frame?

1. To avoid welding deformation of the aluminum gate, symmetrical welding (including butt welding, vertical welding, and oblique welding) is used during welding;

2. During the welding process of the aluminum gate, slag should be removed from each weld seam, and any defects found should be promptly polished with an angular grinding wheel to remove the defects;

3. The welding work for the aluminum gate has been completed. The welding area and welding site of the aluminum gate have been cleaned and transferred to the next welding node.

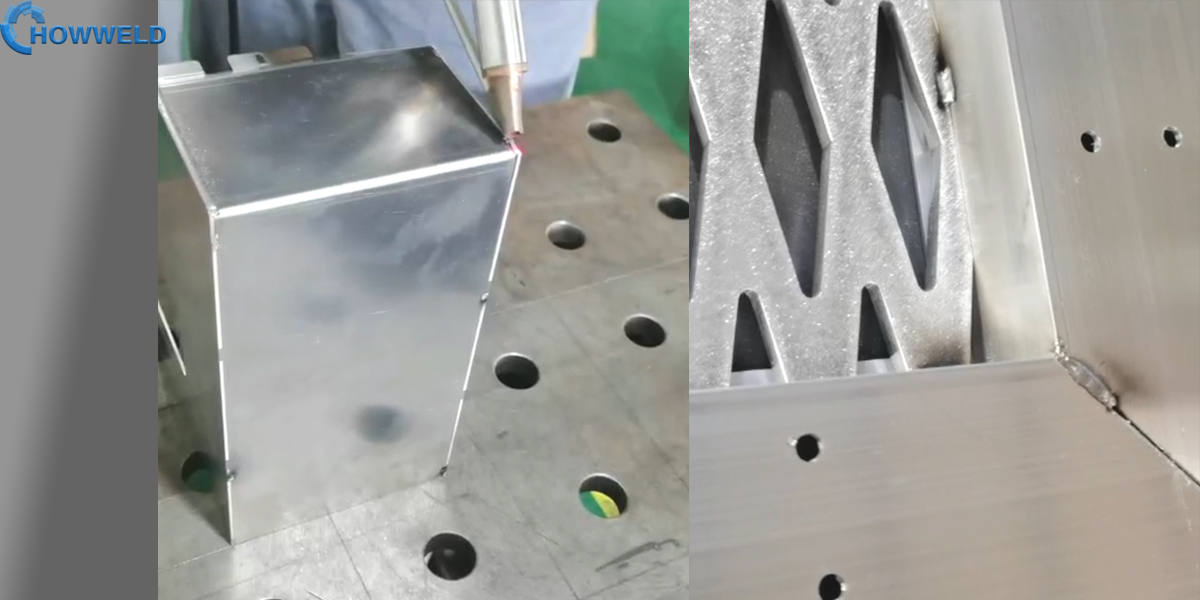

Post weld inspection of aluminum gate: After the welding seam of the aluminum gate cools down, perform a visual inspection of the welding seam; There should be no cracks in the welding seam of the aluminum gate, and the metal in the welding seam should be completely fused with the base material. All cracks should be filled.

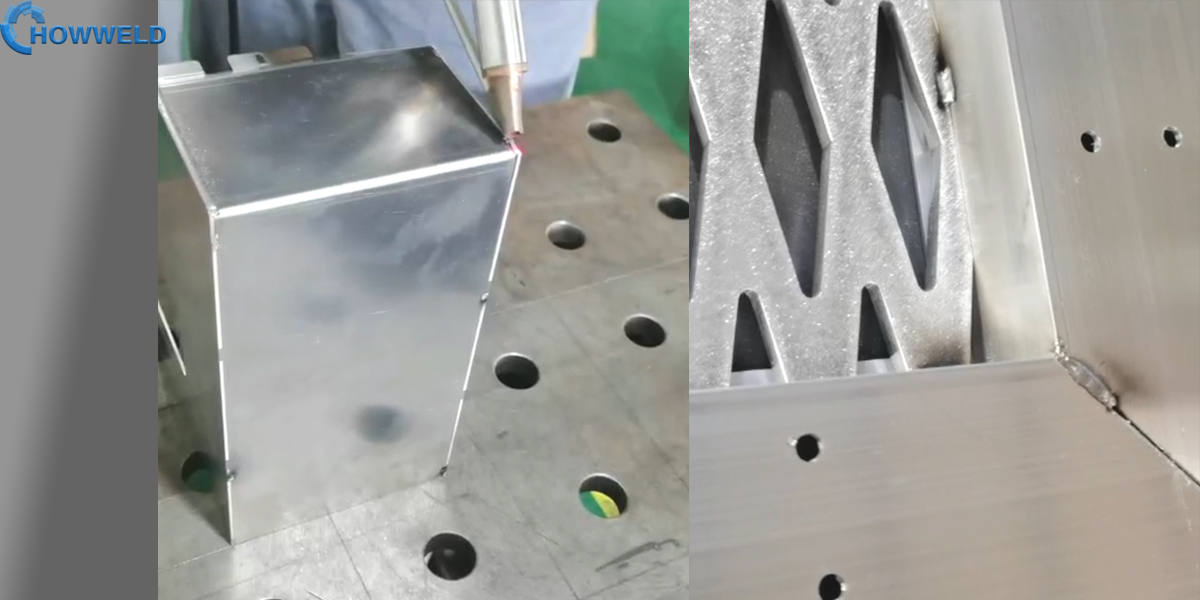

The production process of aluminum alloy doors is relatively simple, and many small manufacturers can produce them, but the quality mainly depends on whether the manufacturing process is fine. The level of welding process reflects the quality of aluminum alloy doors.

High quality aluminum alloy doors, finely processed, with meticulous welding, especially some spliced parts that are very smooth. However, low-quality aluminum alloy doors and windows are blindly selected with aluminum profile series and specifications, processed in a rough and shoddy manner, and the corners of the door frame cannot be smoothly spliced, sometimes even resulting in large gaps.

When consumers make purchases, they should pay attention to checking for welding defects, such as open welding, missing welding, and other phenomena. Also, check whether the door leaf and frame are tightly closed, whether the gap is even and consistent, and whether the opening is flexible.

Reminder:

After inspecting the welding process of aluminum alloy doors, consumers should also carefully check whether the paint surface of the product has bright colors and clear textures, and be careful not to have obvious scratches, bubbles, and other defects on the paint surface.

Recommend suitable machine:

Recommend suitable machine:

Handheld laser welding machine, install with fiber laser source, transfer laser by optical fiber line.

Different thickness aluminium, different kind of material, choose different power machine, we can install higher power to 4kw.

Manual laser welder, it was installed latest generation laser generator.

Different thickness aluminium, different kind of material, choose different power machine, we can install higher power to 4kw.

Manual laser welder, it was installed latest generation laser generator.

Install with wobble head which is developed by famous professional laser head manufacturer in China such as Qilin laser head, WSX laser head, we are howweld factory from shenzhen city which focus on laser welding solution&technology for more than 10 years.

Welding stainless steel sheet, iron sheet, galvanized sheet and titanium other metal materials.

Perfectly replace the traditional argon arc welding, electric welding and other processes.

Welding tags: hand-held laser welder price, welding solution for door frame, laser machine dealer, suppliers, facttory, customized, wholesale laser welding;

Application to widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel/aluminum doors and windows guardrail, distribution boxes, and other industries complex and irregular welding process.

Perfectly replace the traditional argon arc welding, electric welding and other processes.

Welding tags: hand-held laser welder price, welding solution for door frame, laser machine dealer, suppliers, facttory, customized, wholesale laser welding;

Application to widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel/aluminum doors and windows guardrail, distribution boxes, and other industries complex and irregular welding process.

Brief introdution:

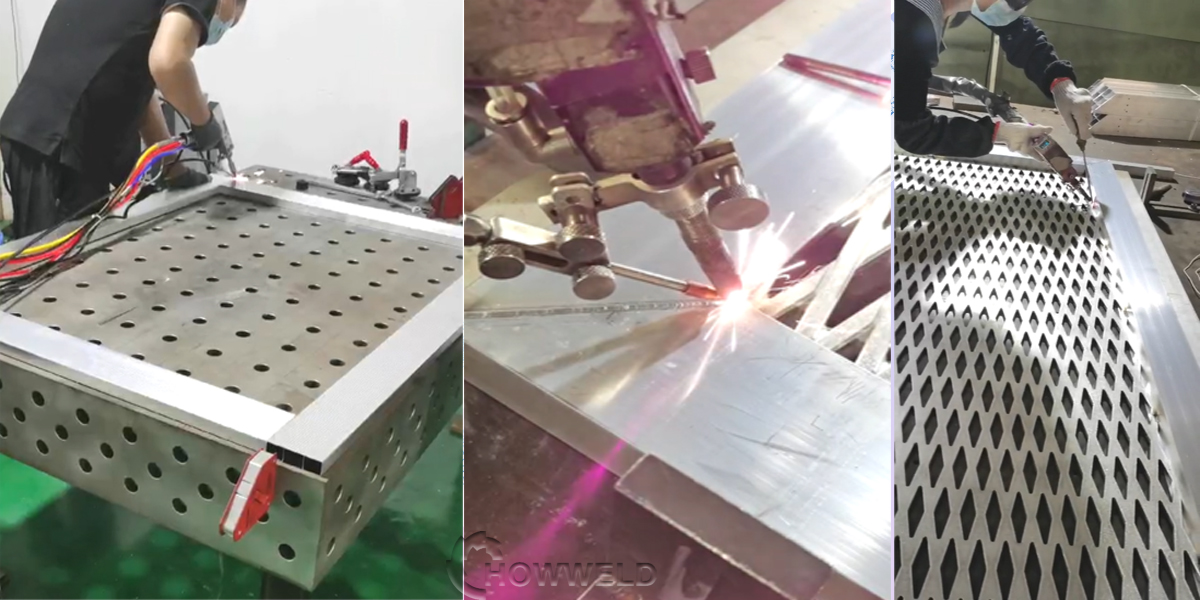

Aluminium door frame

Materials:

2mm aluminium frames

Test handheld type welding:

Test time: 2024.2.21

Samples from: Yangjiang of Guangdong

Welding requirements: Welding firmness and smooth surface

Machine power: 3000W laser power

Set parameter to 65% power, continuous laser beam;

Laser resonator: Raycus 3000w

Welding results:

Enough firmness and smooth surface;

Welding penetration to 81.5%;

Wobble head type choosen;

Above content writed by Howweld Team that we provide copper welding laser processing equipment with service, provide suitable laser welding, laser cleaning solution. Contact email: info@howweld.com

Welcome to inquire, visit and testing samples. We are looking forward to your presence.