Roller repair to save 2 million yuan per year

Time:2024-01-25

Views:432

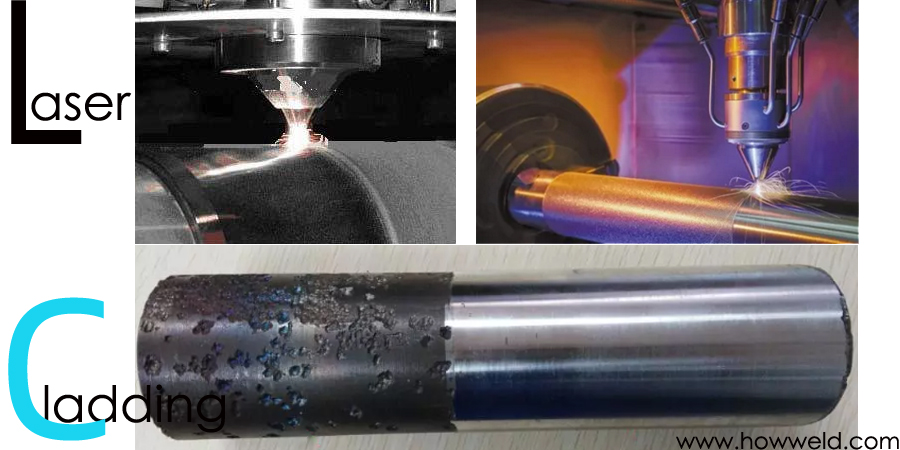

Laser cladding is a process that belongs to the scope of hard surface layer solutions and can be used to improve the corrosion resistance, wear resistance, or impact performance of metal components by applying a completely dense, metallurgical bonded, and almost pure coating.

Laser cladding can be used in various industries.

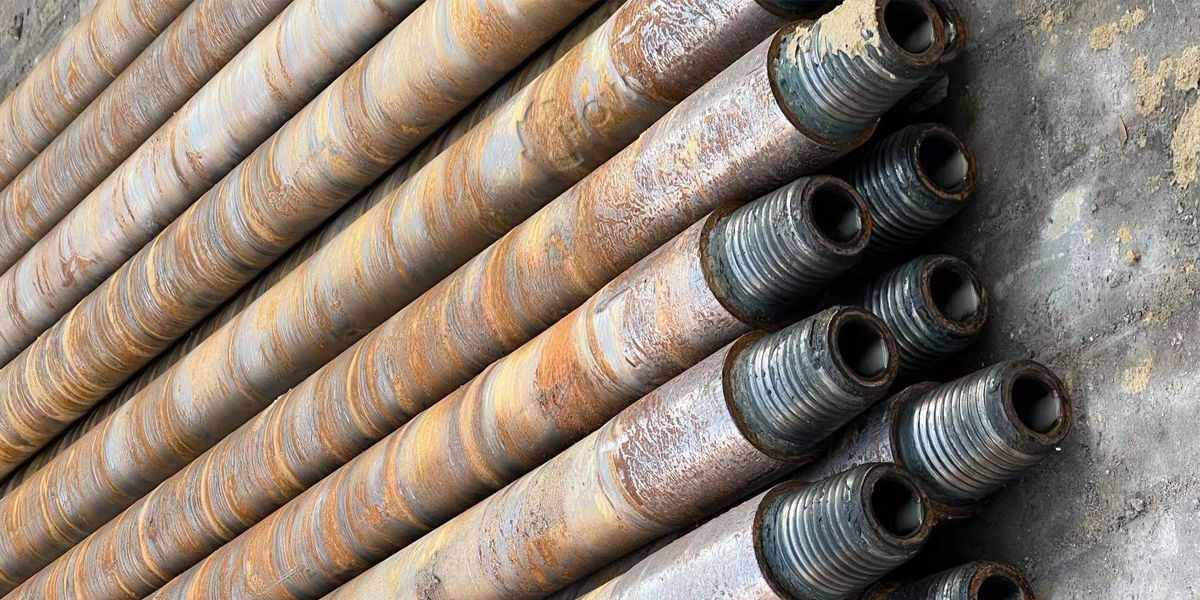

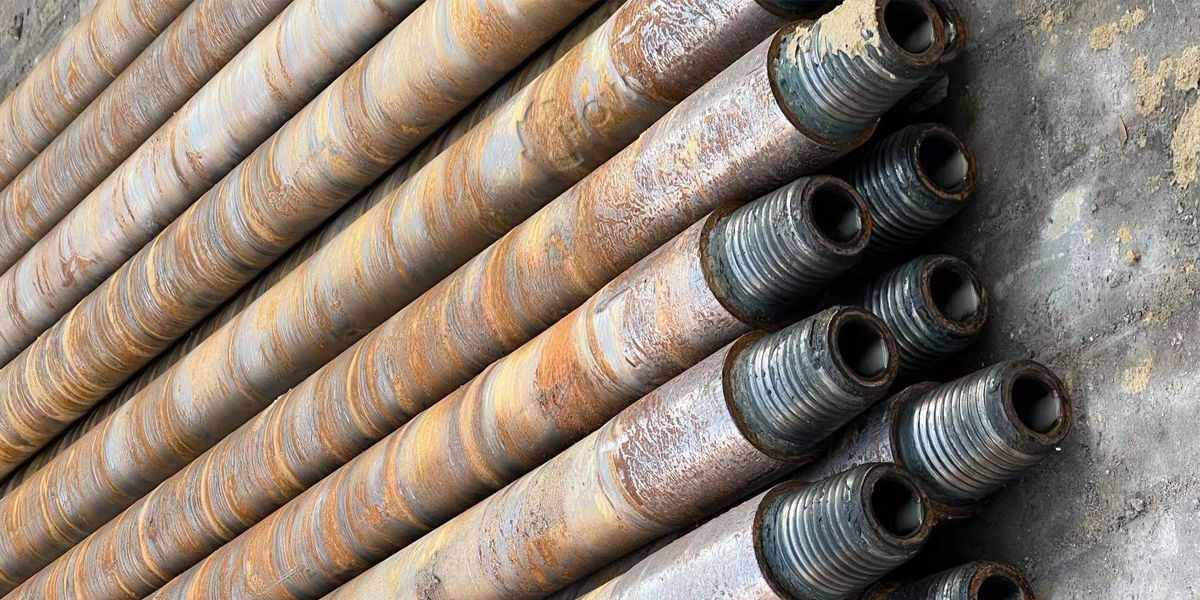

In this case, it is used to repair the drive shaft of large CNC boring machines. The steel drive shaft is worn in two bearing areas and is considered non weldable according to standard methods. Due to the critical dimensions of the shaft and its relatively small size, deformation must be controlled, which is crucial.

The laser cladding process is an ideal solution, with ideal repair results and the ability to produce coatings with higher purity than other traditional welding hard surface processes.

In addition, the very low thermal input associated with lasers minimizes distortion and produces fine microstructures.

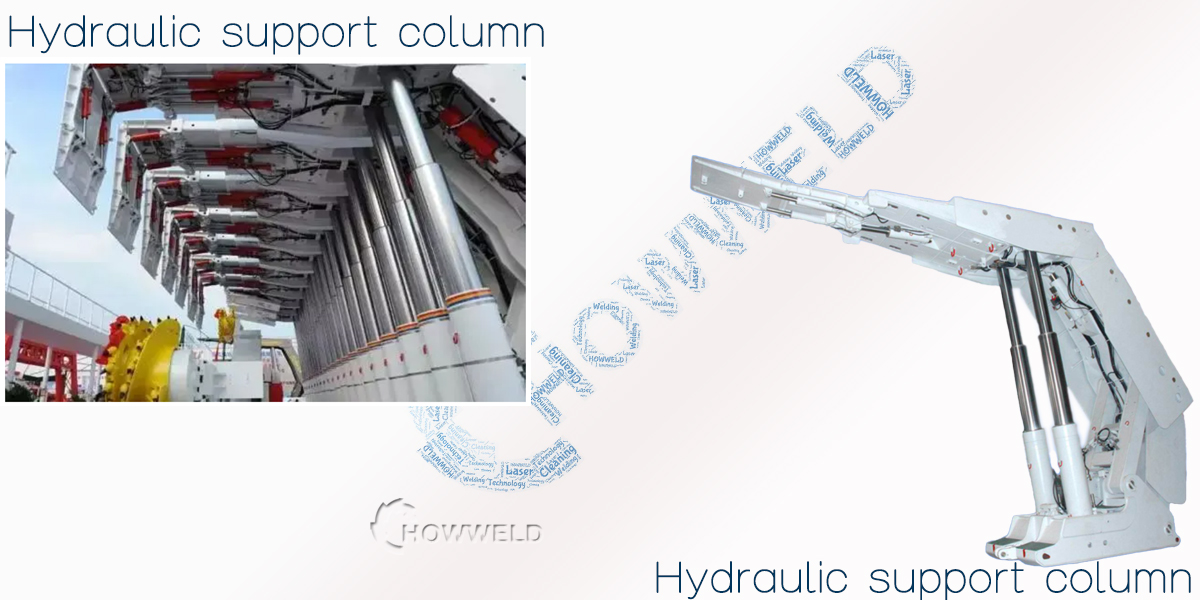

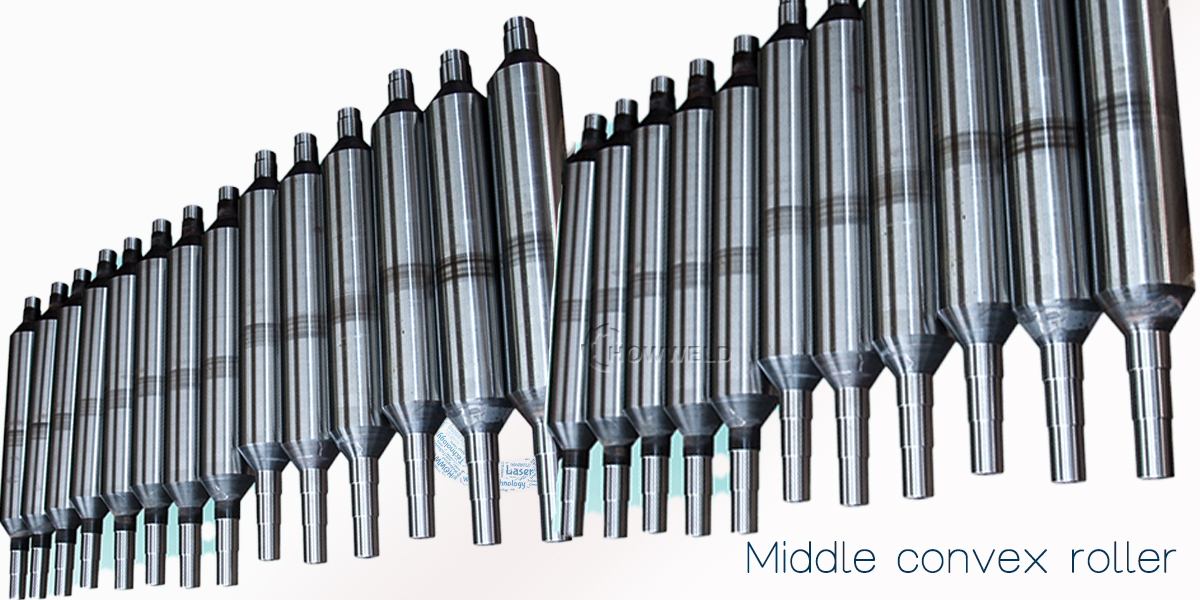

In our steel manufacturing industry in China and other countries, due to component wear, damage, missing corners, cracks, etc., our Howweld R&D team has developed the most suitable machine, which is affordable, practical, and cost-effective to repair parts, helping to recover 2 million yuan in important component losses on various steel rolling production lines every year.

There is no need to replace new equipment parts, but the traditional method is mainly to replace these equipment parts, and even scrap or replace the entire machine because the parts cannot be used. A 3000W power machine can repair the damage, and even our Howweld machine can provide a low-power version of 2000W.

Not only does it result in losses, but also expired and scrapped components will become waste, causing a significant waste of resources.

Laser cladding repair equipment can prepare high-performance alloy surfaces on metal substrates of components, significantly improving their surface wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties. It can not only extend the service life of new components, but also perform cladding repair on worn components to restore their original dimensions, thereby reducing the replacement cycle of components.

Laser cladding repair equipment can prepare high-performance alloy surfaces on metal substrates of components, significantly improving their surface wear resistance, corrosion resistance, heat resistance, oxidation resistance, and electrical properties.

The above content comes from Howweld. A laser equipment manufacturer with suitable price in China, persistently promote the application of laser equipment in various industries, to provide customers with the most suitable solution. Welcome to inquire, visit and testing samples. Email: info@howweld.com

The above content comes from Howweld. A laser equipment manufacturer with suitable price in China, persistently promote the application of laser equipment in various industries, to provide customers with the most suitable solution. Welcome to inquire, visit and testing samples. Email: info@howweld.com