Difference between continuous laser welding and pulse laser welding

Time:2021-08-19

Views:1097

Difference between continuous laser welding and pulse laser welding

Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of laser radiation is guided to the internal diffusion of the material through heat transfer, and the material is melted to form a specific molten pool. Laser welding is one of the important aspects of the application of laser material processing technology. Laser welding machines are mainly divided into pulse laser welding and continuous laser welding.

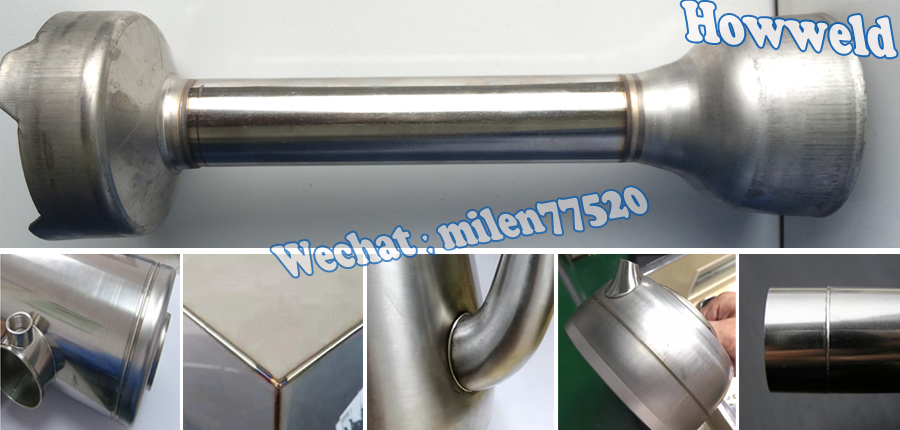

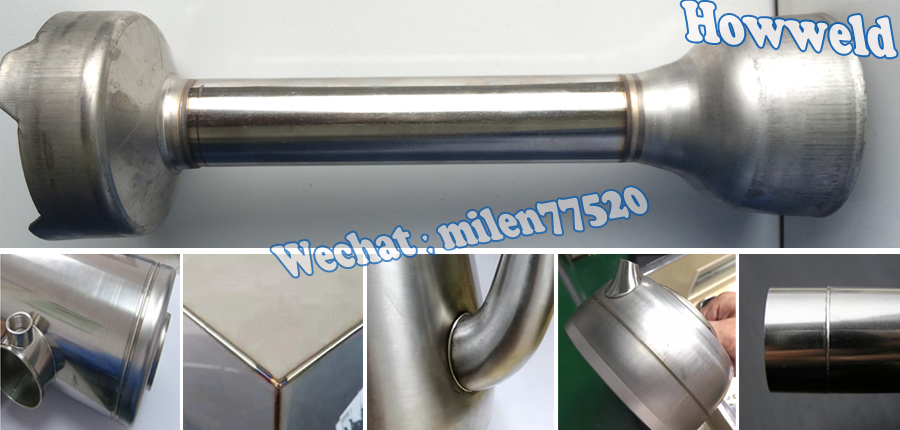

Laser welding is mainly aimed at the welding of thin-walled materials and precision parts, which can realize spot welding, butt welding, overlap welding, seal welding, etc. with high depth width ratio, small weld width, small heat affected zone, small deformation, fast welding speed, flat and beautiful weld, no treatment or simple treatment after welding, high weld quality, no pores, accurate control, small focus light spots and high positioning accuracy, Easy automation.

So what are the differences between continuous laser welding and pulse laser welding?

Analysis on the difference between continuous laser welding and pulse laser welding:

Most of continuous laser welding are high-power lasers with power above 500 watts. Generally, this kind of laser should be used for plates above 1mm. Its welding mechanism is deep penetration welding based on keyhole effect, with large depth width ratio, up to more than 5:1, fast welding speed and small thermal deformation. It is widely used in machinery, automobile, shipbuilding and other industries. There are also some low-power CW lasers with power ranging from tens to hundreds of watts. They are widely used in plastic welding and laser brazing industries.

Howweld factory produce pulse laser welding machine welding for eyewear frames.

Howweld factory produce pulse laser welding machine welding for eyewear frames.

Pulse laser is mainly used for spot welding and seam welding of thin-walled metal materials with a thickness of less than 1mm. Its welding process belongs to heat conduction type, that is, laser radiation heats the surface of the workpiece, then guides the internal diffusion of the material through heat transfer, and forms a good connection between the workpieces by controlling the parameters such as laser pulse waveform, width, peak power and repetition frequency. It is widely used in 3C product shell, lithium battery, electronic components, mold repair welding and other industries.

The biggest advantage of pulsed laser welding is that the overall temperature rise of the workpiece is very small, the heat influence range is small, and the workpiece deformation is small.

Laser welding belongs to fusion welding, which uses laser beam as energy to impact on the weldment joint. The laser beam can be guided by a planar optical element (such as a mirror) and then projected on the weld with a reflective focusing element or lens. Laser welding belongs to non-contact welding, and pressure is not required during operation, but inert gas is required to prevent oxidation of molten pool, and filler metal is occasionally used.

Laser welding and MIG welding can form laser MIG hybrid welding to realize large penetration welding, and the heat input is greatly reduced compared with MIG welding.

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com

Laser welding and MIG welding can form laser MIG hybrid welding to realize large penetration welding, and the heat input is greatly reduced compared with MIG welding.

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com