Difference between handheld laser welding and automatic laser welding

Time:2021-08-23

Views:1089

Difference between handheld laser welding and automatic laser welding

Laser welding, also known as laser welding machine, is a kind of laser material processing equipment. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation is transferred to the material through heat to melt the material to form a specific molten pool.

Laser welding is a new type of welding method. It is mainly used for welding thin-walled materials and precision parts. It can realize spot welding, butt welding and sealing welding. Small area, small deformation, fast welding speed, smooth and beautiful welding seam, no need to handle or simple processing after welding, high welding seam quality, no porosity, precise control, focus on the scene, accurate positioning, easy to realize automation.

Analysis of the difference between handheld laser welding machine and automatic laser welding machine

When consumers purchase laser welding, they will customize it to the laser manufacturer according to their own product requirements. Of course, there are also some standard production models. This process has a small part of the process to choose from (handheld laser welding machine), and you can choose manual laser spot Welding machine or automatic laser spot welding machine can meet product welding requirements.

Hand-held laser welding machine, as the name suggests, manual laser welding machine is a kind of equipment that requires manual welding. It can perform laser welding for a long distance and large-size workpieces. The welding heat affected zone is small and will not cause problems, such as deformation, black, Marking, and deep welding, welding company, soluble punching bumps and the matrix after the combination of no molten holes.

The automatic laser welding machine is a kind of automatic welding equipment, which uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation is transferred to the inside of the material through heat, so that the material is melted to form a specific molten pool. Thin-walled materials are used to weld precision parts, which can realize spot welding, butt welding, surfacing welding, sealing and other welding. The welding width is small, the welding speed is fast, the welding quality is good, there is no air hole, it can be accurately controlled, the positioning accuracy is high, and it is easy to realize automation.

The difference between automatic laser welding machine and hand-held laser welding machine.

The automatic laser welding machine automatically performs welding according to the set procedure after the software is set up; the manual laser welding machine is also called spot welding, which is the visible spot welding on the screen through high magnification manually.

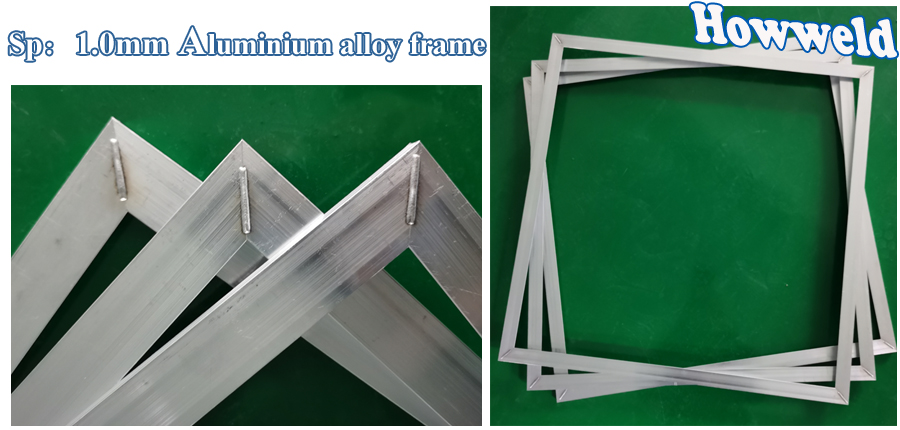

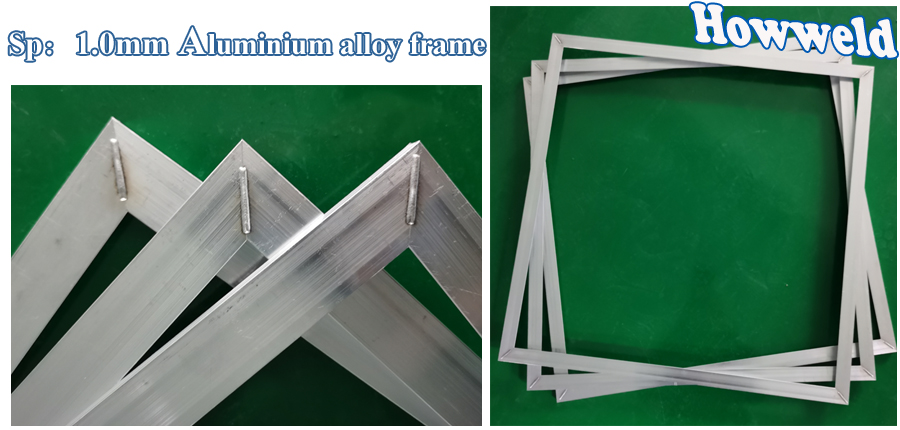

Howweld team produce cheapest price laser welding machine from Shenzhen.

Hand-held laser welding machine automatic installation equipment deployment, compared to sporadic processing or large welding production workshops, a hand-held laser welding edge does not need to install and debug the automatic laser welding platform and take up space environment. The important thing is that there are many different types of small workshops. The welding products are not strong enough. Therefore, handheld laser welding can meet such production needs and has better compliance.

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com

The above content comes from Howweld.A famous laser equipment manufacturer in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com