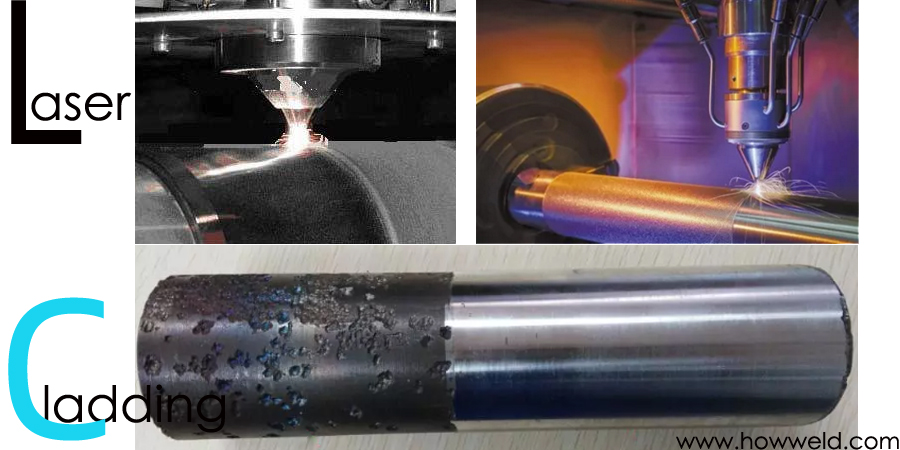

Laser cladding for shaft blades alternator shaft and bearing repair

Time:2023-03-10

Views:645

Laser cladding machine for repair shaft blades alternator shaft and bearing

In practical application, due to corrosion, high-temperature oxidation, friction and wear, the inner surface of the tubular part is often severely damaged, resulting in shortened life and large economic losses in engineering applications.

Therefore, it is very important to carry out laser cladding repair treatment on the inner wall surface of the metal tube to make it have higher hardness, better friction and wear resistance, high temperature resistance, pressure resistance, corrosion resistance, etc. practical significance. The following introduces the repair process of the metal inner wall laser cladding technology;

The performance of the traditional electroplating coating is insufficient, and more importantly, the electroplating solution has serious pollution to the environment. Today, with the increasing requirements for environmental protection, the electroplating industry is gradually being replaced. This refers to a new process that replaces the electroplating industry: laser cladding technology.

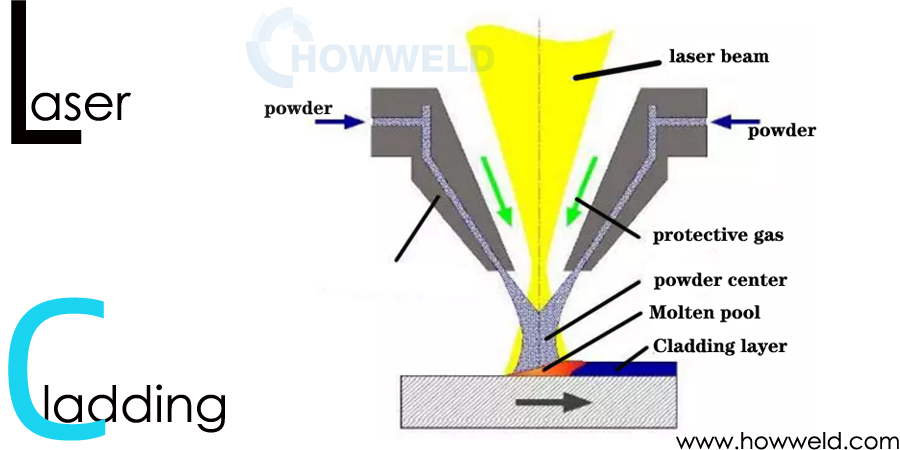

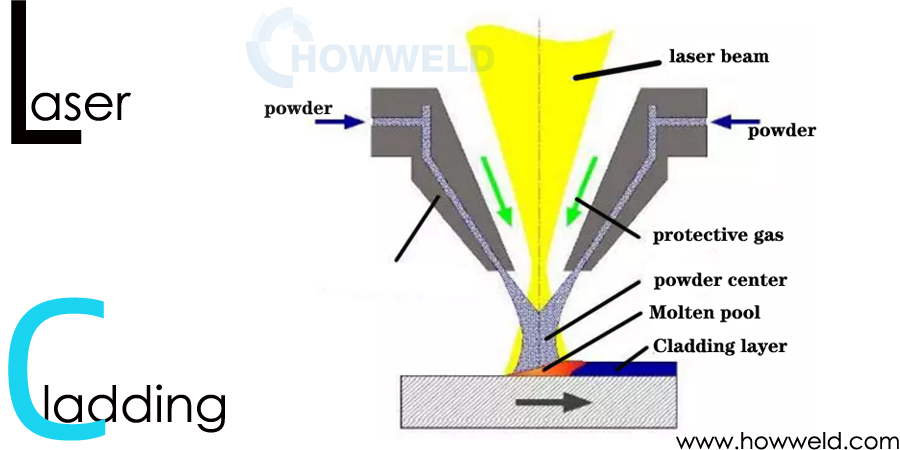

Laser cladding is a laser surface repair treatment technology that melts the required alloy powder into the main alloy of the cladding layer without laser melting. The cladding layer and the base metal are melted with a thin layer to form a metallurgical combination.

The inner surface of the tubular material can be treated by using the high energy density and high directionality of the laser, so that the performance of the inner surface of the tubular workpiece can be improved, especially the hardness, strength, wear resistance, corrosion resistance and high temperature resistance of the inner surface can be improved. The service life of the tubular material is thereby increased.

Components in the drilling, exploration and extraction of Oil & Gas are exposed to severe wear corrosion and erosion. Reliability of these components in critical to mitigate lost production time and significant financial losses.

These tough drilling environments require the best protection and surface technologies to extend the life of critical oilfield tools; providing superior protection against abrasion, erosion and corrosion.

The key beneficial properties of laser cladding is integral to this protection and results in improved reliability, long life, and reduced down time.

Laser cladding is fast becoming the industry standard in the oil and gas field.

Laser cladding is realized in the form of metal wire (laser hot wire cladding) or powder cladding. The laser beam forms a molten pool on the surface of the workpiece, and the laser coating material (wire or powder) melted by the laser is added to it. The exposure time is very short. Because the cooling is very fast, only a short delay will occur. The result is that one layer is metallurgically connected with the base material. It is tougher than the coating formed by thermal spraying, and it is harmless to health compared with hard chromium coating, for example.

Laser cladding is realized in the form of metal wire (laser hot wire cladding) or powder cladding. The laser beam forms a molten pool on the surface of the workpiece, and the laser coating material (wire or powder) melted by the laser is added to it. The exposure time is very short. Because the cooling is very fast, only a short delay will occur. The result is that one layer is metallurgically connected with the base material. It is tougher than the coating formed by thermal spraying, and it is harmless to health compared with hard chromium coating, for example.

Laser cladding refers to the process of placing the selected coating material on the surface of the coated substrate in different feeding ways, and then melting it with a thin layer of the substrate surface by laser irradiation, and rapidly solidifying it to form a surface coating with extremely low dilution and metallurgical combination with the substrate, which can significantly improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the substrate surface, so as to achieve the purpose of surface modification or repair, It not only meets the requirements for specific properties of the material surface, but also saves a lot of valuable elements. Howweld factory offer suitable cladding machine.

.jpg)

.jpg)

Compared with surfacing, spraying, electroplating and vapor deposition, laser cladding has the characteristics of low dilution, compact structure, good bonding between coating and substrate, multiple materials suitable for cladding, and large changes in particle size and content. Therefore, the application prospect of laser cladding technology is very broad.

The complete equipment of Howweld 3000W optical fiber cladding system is a large-scale integrated equipment integrating optical, mechanical, electrical, refrigeration and material processing technologies. The equipment has the functions of laser cladding, laser cladding, laser alloying, etc. The 3000W fiber laser cladding system has the ability to move to the site for laser processing.