Laser cutting technology helps the production of elevator industry

Time:2021-11-03

Views:977

After several years of precipitation, fiber laser technology has become very mature and gradually entered the field of industrial manufacturing. Industrial laser manufacturing equipment has been widely used in production lines in all walks of life in recent years. Many objects in life are related to laser technology. This paper mainly introduces the laser technology applied in elevator products in the construction industry.

Elevator is a product that we can often touch in our life. Its emergence provides great convenience for life. It originated in western countries and was gradually widely used in high-rise buildings.

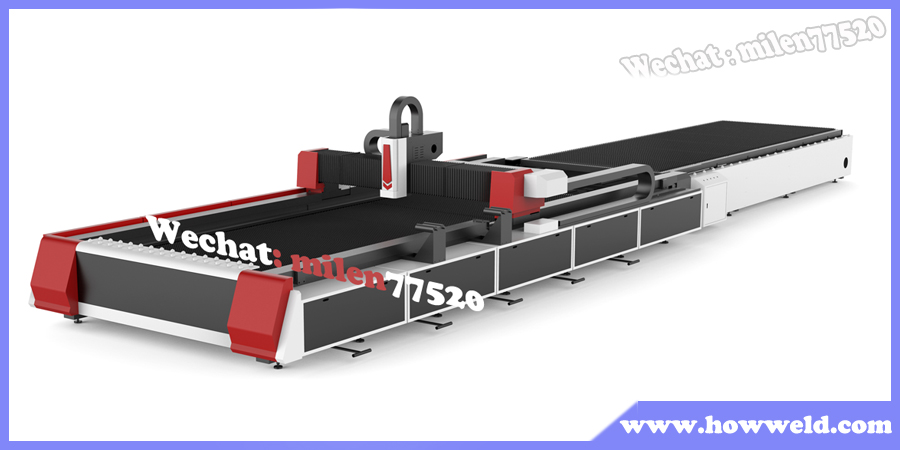

At present, there are two mainstream elevators in the market: vertical elevator and escalator. Elevator is widely used in residential high-rise buildings, office buildings and other high-rise buildings, while escalator is mainly used in shopping malls, hospitals and other places on low floors.Howweld company design small size,medium size and large size cutting range such as 600*600mm,800mm,3000*1500mm laser cutting range.

The main structure of elevator is composed of car body, traction part, control system, automatic door, safety system, etc. A large number of steel plates are used in the elevator, such as the door and car body in the elevator, the pedal transmission part in the elevator, the walls on both sides, etc. These parts are mainly processed by laser cutting process.

The elevator itself needs to have a certain bearing capacity, and the steel plate structure is very suitable. When the laser cutting machine is not widely used, the elevator manufacturing also adopts the traditional punch, sawing and other methods.Because this method is not efficient, and the steel plate often needs to be polished after edge cutting, it is prone to errors, which is not conducive to the subsequent precise structure.

Elevators not only need stable performance, but also have certain requirements on appearance precision. In shopping malls and other public places, the beauty of elevators will also have a certain impact on people‘s shopping psychology.

At present, there is no requirement for the thickness of steel plate of elevator car body and door in the national standard, only the strength requirement

Generally speaking, 304 stainless steel with a thickness of 0.8mm is commonly used, and some steel plates with a thickness of 1.2mm are also used. Considering the cutting production speed, the steel plate with this thickness can generally be cut and processed quickly at 3000W. The section of the processed workpiece is flat and has high precision. The welding process can be carried out directly without grinding.

With the laser cutting machine, the overall production of the elevator industry will be upgraded to a higher level. It is optimistic that the processing demand of elevators and related products in the future can bring hundreds of cutting or welding equipment to the laser industry every year, which is a subdivided field in which laser technology can play an important role.

Above content writed by Howweld Team that we provide laser processing equipment with service,provide suitable laser welding,laser cleaning solution.Contact email:info@howweld.com

Welcome to inquire, visit and testing samples.We are looking forward to your presence.