Three minutes to understand laser cleaning technology

Time:2022-05-26

Views:843

Three minutes to understand laser cleaning technology

The high-energy pulse laser is generated by the pulse laser and transmitted to the shaping module through the optical fiber. After being reflected by the uniaxial or biaxial scanning galvanometer, it irradiates the dirt layer on the workpiece surface to vaporize, light peel, light decomposition and light vibration on the rust, paint, oil stain, oxide skin, coating and other attachment layers on the workpiece surface.

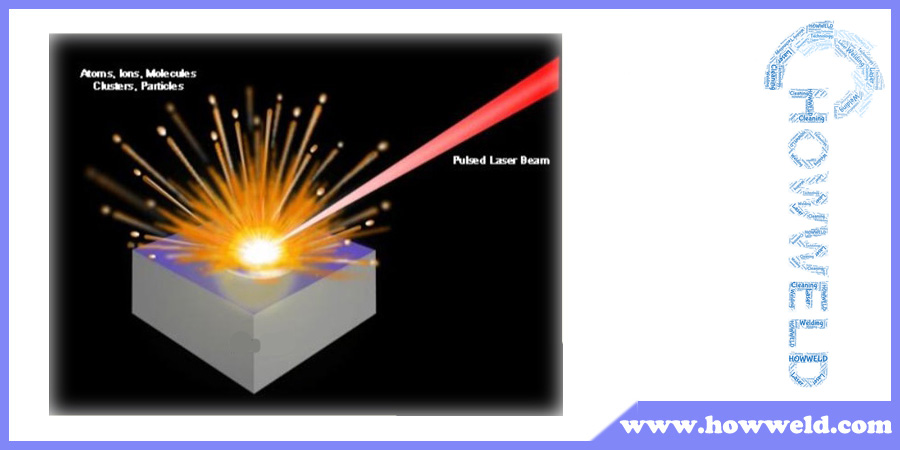

The scientific name of laser cleaning is laser ablation. Laser ablation or light ablation is the process of removing materials from solid (or sometimes liquid) surfaces by irradiating with a laser beam. At low laser flux, the material is heated and evaporated or sublimated by the absorbed laser energy.

At high laser flux, materials are usually converted to plasma. Generally, laser ablation refers to the removal of materials with pulsed laser, but if the laser intensity is high enough, the materials can be ablated with continuous wave laser beam. Deep ultraviolet excimer lasers are mainly used for optical ablation. The laser wavelength for optical ablation is about 200 nm.

At high laser flux, materials are usually converted to plasma. Generally, laser ablation refers to the removal of materials with pulsed laser, but if the laser intensity is high enough, the materials can be ablated with continuous wave laser beam. Deep ultraviolet excimer lasers are mainly used for optical ablation. The laser wavelength for optical ablation is about 200 nm.

Working mechanism of laser cleaning

Laser has the characteristics of high intensity, high energy density, strong focusing and good directionality.

Laser cleaning technology uses the vibration of laser pulse, thermal expansion of particles, photodegradation or phase transformation of molecules or their combined action to overcome the binding force between dirt and substrate surface and make dirt separate from the surface to achieve the purpose of cleaning.

Laser cleaning technology uses the vibration of laser pulse, thermal expansion of particles, photodegradation or phase transformation of molecules or their combined action to overcome the binding force between dirt and substrate surface and make dirt separate from the surface to achieve the purpose of cleaning.

Industrial laser cleaning is a process of irradiating the solid surface with a laser beam to remove unwanted materials. By absorbing the energy of the laser beam, the target material (the surface layer to be removed) is rapidly heated to evaporate or sublimate. Since the substrate surface does not absorb any energy (or absorbs very little energy), it remains as it is. Howweld team design a 1kg laser head for laser cleaning system which workers doing cleaning works can last for a long time, even works for 1 hour or two hours.

By controlling the luminous flux, wavelength and pulse length of the laser, the amount of material removed by a single laser pulse can be controlled very accurately.

By controlling the luminous flux, wavelength and pulse length of the laser, the amount of material removed by a single laser pulse can be controlled very accurately.

|

Comparision

|

Laser Cleaning

|

Chemical Cleaning

|

Mechanical Grinding

|

Dry ice cleaning

|

|

Washiing Method

|

non-contact cleaning

|

contact cleaning

|

Abrasive contact cleaning

|

non-contact cleaning

|

|

Harm to base material

|

None

|

Yes

|

Yes

|

None

|

|

Washing Efficiency

|

High

|

Low

|

Low

|

Mid.

|

|

Consumable

|

Power

|

Chemical Detergent

|

Abrasive paper, grinder, abrasive stone

|

Dry Ice

|

|

Washing result

|

Very good, very clear

|

Medium, uneven

|

Medium, uneven

|

Good, uneven

|

|

Precision Washing

|

Accuracy controllable. High precision

|

Uncontrollable, low precision.

|

Uncontrollable, medium precision.

|

Uncontrollable, poor precision.

|

|

Safety/Environment

|

No pollution

|

Chemical pollution

|

Dust pollution

|

No pollution

|

|

Operation

|

Easy to operate, portable or automation optional.

|

Complicated process, higher technical requirement of the operator. Pollution prevention measures required.

|

Need more time & manpower. Pollution prevention measures required.

|

Easy to operate, portable or automatic.

|