What is laser cleaning?

Time:2021-10-18

Views:1033

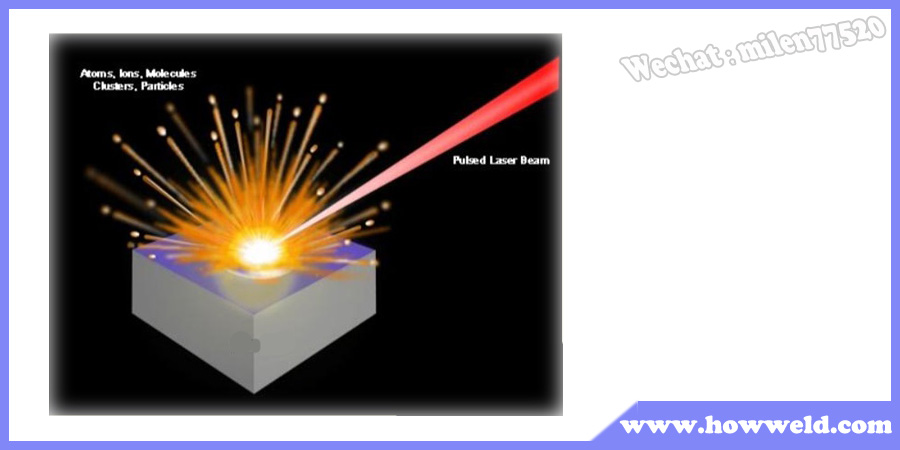

The scientific name of laser cleaning is laser ablation. Laser ablation or light ablation is a process of removing materials from solid (or sometimes liquid) surfaces by irradiating with a laser beam. At low laser flux, the material is heated and evaporated or sublimated by the absorbed laser energy. At high laser flux, materials are usually converted to plasma. Generally, laser ablation refers to the removal of materials with pulsed laser, but if the laser intensity is high enough, the materials can be ablated with continuous wave laser beam. Deep ultraviolet excimer lasers are mainly used for optical ablation. The laser wavelength for optical ablation is about 200 nm.Howweld manufacturer design 0.8kg cleaning head,for easy to operate cleaning and not feel tired when work for long time.

.jpg)

Laser cleaning is a laser application technology, which is used in industry, biology and medical treatment.

Principle of laser cleaning 1)medical care

When it comes to laser cleaning, many people will think of washing tattoos. It uses CO2 or Nd: YAG pulsed laser to clean the surface, remove pigmentation, improve the appearance of scar tissue (incurable), and restructure the outer layer of the skin without damaging the outer layer, as shown in the table below. In fact, it is used in a variety of medical specialties, including ophthalmology, general surgery, neurosurgery, otolaryngology, dentistry, oral and maxillofacial surgery and veterinary medicine. Laser scalpels are used to ablate hard and soft tissues. Some of the most common medical applications using laser ablation include LASIK, skin replacement, cavity preparation, biopsy, and tumor and lesion removal. In soft tissue surgery, CO2 laser beam ablation and cauterization at the same time, making it the most practical and common soft tissue laser. There are several types of lasers used in medicine, including argon, carbon dioxide (CO2), dyes,, excimer, Nd: YAG, etc.

Laser cleaning can be used for benign and malignant lesions of various organs, which is called laser-induced interstitial hyperthermia. At present, the main applications include reducing benign thyroid nodules.

2)Industry

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Laser cleaning is a "green" cleaning method, which does not need to use any chemical agent and cleaning solution. The cleaned waste is basically solid powder, small in volume, easy to store and recyclable, which can easily solve the environmental pollution caused by chemical cleaning;

2. The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium is attached to the surface of the cleaned object, which cannot be removed and produces secondary pollution. The non grinding and non-contact of laser cleaning can solve these problems;

3. Laser can be transmitted through optical fiber and cooperate with manipulator and robot to realize remote operation conveniently. It can clean parts that are difficult to reach by traditional methods, which can ensure personnel safety in some dangerous places;

4. Laser cleaning can remove various types of pollutants on the surface of various materials to achieve the cleanliness that conventional cleaning cannot achieve. It can also selectively clean the pollutants on the material surface without damaging the material surface;

5. Laser cleaning has high efficiency and saves time;

6. Although the one-time investment in the purchase of laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time, with low operation cost and only electricity charge per hour.

In short, it is especially suitable for metals, ceramics and rubber for tires with low cost and good effect.

Cleaning of tire mold and other molds:

Every year, tire manufacturers all over the world manufacture hundreds of millions of tires. In the production process, the cleaning of tire molds must be rapid and reliable to save downtime. Traditional cleaning methods include sand blasting, ultrasonic or carbon dioxide cleaning, but these methods usually must be moved to the cleaning equipment for cleaning after the high heat mold is cooled for several hours. The cleaning takes a long time and is easy to damage the accuracy of the mold. Chemical solvents and noise will also produce problems such as safety and environmental protection.

Using the laser cleaning method, because the laser can be transmitted by optical fiber, it has deep elasticity in use; Because the laser cleaning method can be connected with optical fiber to guide the light to the dead corner of the mold or the part that is not easy to remove for cleaning, it is convenient to use;

Since the rubber is not gasified, it will not produce toxic gas and affect the safety of the working environment. The technology of laser cleaning tire mold has been widely used in European and American tire industry. Although the initial investment cost is high, the benefits obtained in saving standby time, avoiding mold damage, working safety and saving raw materials can be quickly recovered.

According to the cleaning test of the laser cleaning equipment on the production line of the tire company, it can clean a set of large truck tire molds online in only 2 hours. Compared with conventional cleaning methods, the economic benefits are obvious.

.jpg)

Steel cleaning

The general method of steel cleaning in China is pickling, which seriously pollutes the environment. Laser cleaning is in the state of research and development in this aspect. If it is successful, it will be a technological revolution.

The above content comes from Howweld.A laser equipment manufacturer with suitable price in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com

The above content comes from Howweld.A laser equipment manufacturer with suitable price in China,persistently promote the application of laser equipment in various industries,to provide customers with the most suitable solution.Welcome to inquire, visit and testing samples.Email:info@howweld.com