Which brand laser source should be choosen when purchase laser machines?

Time:2024-12-09

Views:180

Which brand laser source should be choosen when purchase laser machines?

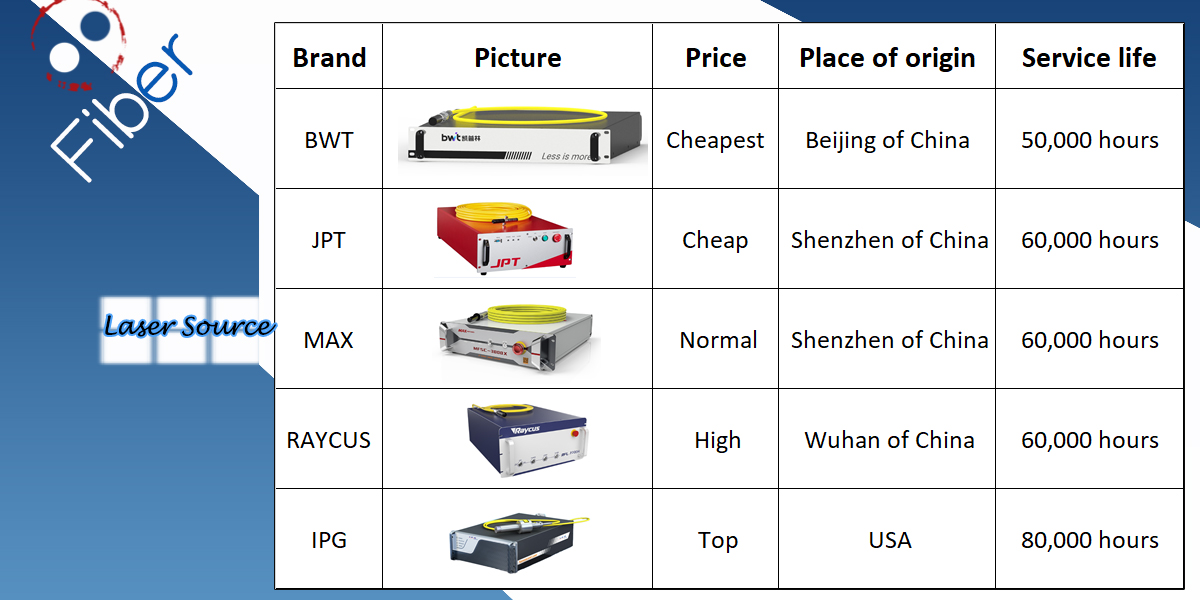

When choosing a laser welding machine, the laser is one of the core components, and the choice of brand will directly affect the performance, stability and after-sales service of the equipment. The following are recommended laser brands and their characteristics for your reference:

1. Internationally renowned laser brands

These brands have mature technology and strong stability, but the price is relatively high, suitable for high-end markets and complex application scenarios.

IPG Photonics

Features: The world‘s leading fiber laser brand, with stable product performance, high photoelectric conversion efficiency, and suitable for high-precision welding.

Application scenarios: high-end manufacturing industries (such as automobile manufacturing, aerospace).

Advantages:

High beam quality.

Long service life and low maintenance cost.

Disadvantages: Expensive, suitable for companies with sufficient budgets.

Trumpf

Features: German brand, known for quality and technological innovation, providing fiber lasers and carbon dioxide lasers.

Application scenarios: automobile, electronics, and medical equipment manufacturing.

Advantages:

The laser has strong reliability.

Excellent after-sales service.

Disadvantages: High equipment price and maintenance costs.

nLIGHT

Features: American brand, famous for high-power fiber lasers, suitable for welding of highly reflective materials (such as aluminum and copper).

Application scenarios: battery manufacturing, new energy industry.

Advantages:

Excellent anti-high reflection performance.

Wide power range coverage.

Cons: Some high-end models are more expensive.

2. Well-known domestic laser brands

Domestic laser brands have made significant technological progress in recent years and are cost-effective, making them suitable for small and medium-sized enterprises or users with limited budgets.

Features: China‘s leading local fiber laser brand, covering product lines from low to medium power to high power.

Application scenarios: metal processing, automotive, consumer electronics industries.

advantage:

High cost performance and large market share.

The after-sales service network is wide and the response speed is fast.

Disadvantages: There is still a gap between high-end products and international brands.

MAX Photonics

Features: Focusing on high cost performance and stability, the technology is gradually approaching the international level.

Application scenarios: metal cutting, welding and other industrial processing fields.

advantage:

Low cost and suitable for start-ups.

Laser stability is significantly improved.

Disadvantages: Market awareness is relatively low.

Han‘s Laser

Features: China‘s leading company in laser processing equipment, providing lasers and complete solutions.

Application scenarios: Widely used in laser welding needs of various industries.

advantage:

Strong technical integration capabilities and complete supporting services.

Disadvantages: The independent performance of the laser is slightly inferior to international brands such as IPG.

Howweld team provide Key factors for choosing a brand

Budget:

High budget: Choose international brands (such as IPG, Trumpf), quality and performance are more guaranteed.

Medium and low budget: Domestic brands such as Raycus Laser and Max Laser are more cost-effective.

Welding materials:

Highly reflective materials (such as aluminum and copper): nLIGHT, IPG and other brands are recommended.

Ordinary metals (such as stainless steel and carbon steel): Domestic brands can basically meet the needs.

Application requirements:

High-end manufacturing: International brands (IPG, Trumpf) are preferred.

Mass production or conventional processing: Domestic brands (Raycus, Max Laser) are more economical and practical.

After-sales service:

If the response time for after-sales service is high, it is recommended to choose local or domestic brands (such as Raycus and Daju).

Equipment support:

Ensure that the laser is well matched with other components of the whole machine (such as galvanometer and control system).

Suggestion: According to your budget, welding material type and application scenario, choose the laser brand with the most suitable comprehensive performance. If it is a first-time purchase, it is recommended to contact multiple suppliers to obtain a sample test opportunity to judge whether the brand performance meets the needs from the actual effect.