Which type of laser welding machine can weld automotive components?

Time:2024-11-04

Views:231

Laser welding has become an essential equipment in the production process of automobiles. In automobile manufacturing, laser welding technology is widely used for welding multiple components due to its high efficiency, precision, and high quality characteristics.

The close relationship between automotive parts welding and laser welding.

The wide application of laser welding: In the automotive manufacturing industry, laser welding technology has become an important means of connecting automotive components. Its efficient, high-precision, and high-quality characteristics make it an indispensable part of automotive manufacturing.

Improving component performance: Laser welding can ensure consistency and high precision of automotive components, enhancing the stability and reliability of the entire power system. At the same time, high-strength solder joints enhance the durability and safety of components, meeting the demands of automobiles for lightweight, high-strength, and precision.

Welding of various components: Laser welding is not only applied to body structural components such as car roofs and frames, but also widely used for welding precision components such as steering systems, transmission systems, safety systems, and power batteries in hybrid vehicles, improving the overall performance and safety of the vehicle.

Laser welding technology is closely related to the welding of automotive components, providing efficient and precise solutions for automotive manufacturing and promoting the sustainable development of the automotive industry.

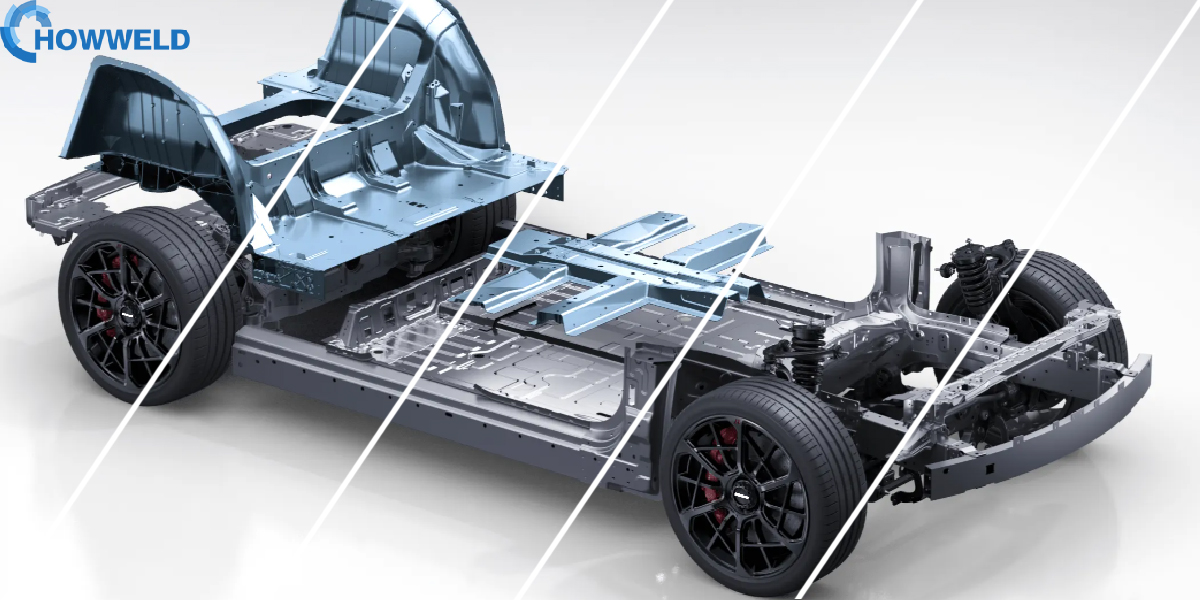

Laser welding machines have become essential equipment in automobile body production, reducing the overall weight of automobile bodies, improving assembly accuracy, and meeting the needs of lightweight and safety performance improvement in automobile manufacturing. In the production process of automobile parts, they are mainly used for welding multiple parts such as gears and transmission components, LED lights, engine exhaust pipes, turbochargers, and plastic dashboard of automobiles. According to different parts of the car, which types of welding machines are generally used in cars

The laser welded components used in automobile manufacturing mainly include the following categories:

1. Body structural components: such as the roof, trunk lid, frame, doors, body side frame, and pillars. Laser welding can improve the strength of the body and solve the problem that conventional resistance spot welding is difficult to implement.

2. Unequal thickness laser welding plate: used in car body manufacturing, it can reduce the weight of the car body, reduce the number of parts, improve safety and reliability, and reduce production costs.

3. Precision components of automobiles, such as steering systems, transmission systems, safety systems, and power battery cells, PACKs, modules, etc. in hybrid vehicles, laser welding can improve connection strength and durability, reduce weight and volume.

4. Other components: such as car wiring harnesses, connections between car lights and other electronic components, car interior parts, etc. Laser welding can improve welding quality and efficiency, and reduce labor intensity.

The application of laser welding technology has improved the performance and appearance of automobiles, meeting the market‘s demand for high-quality cars.