Automatic laser cleaning machine - Manual laser cleaning equipment

---Brings efficiency for rust removal

Main parts list:

1. Fiber laser source

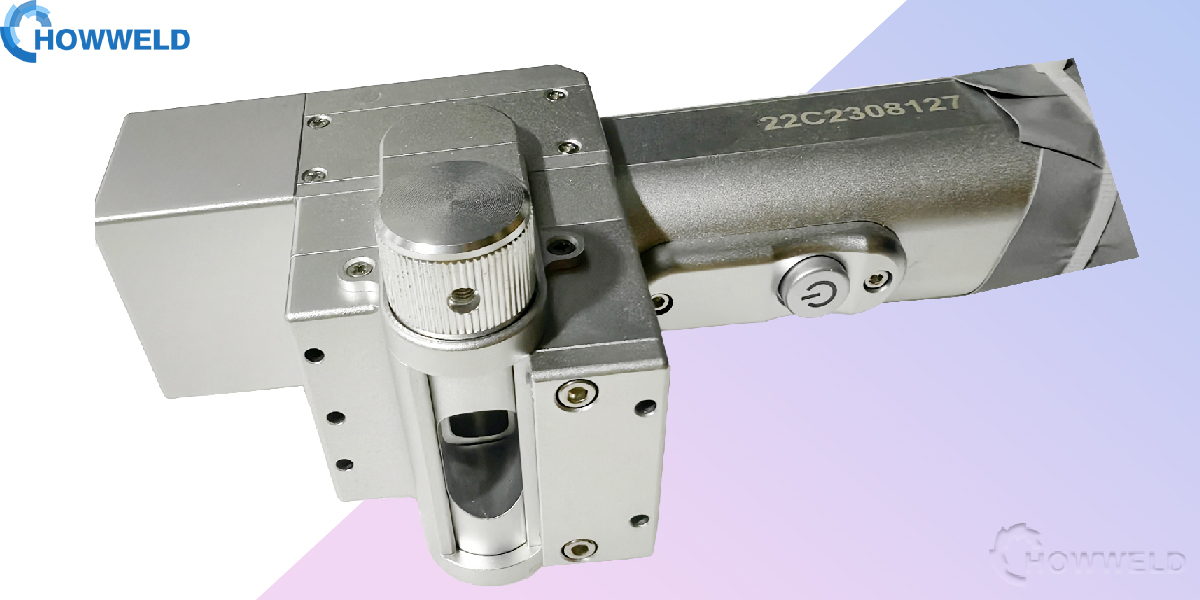

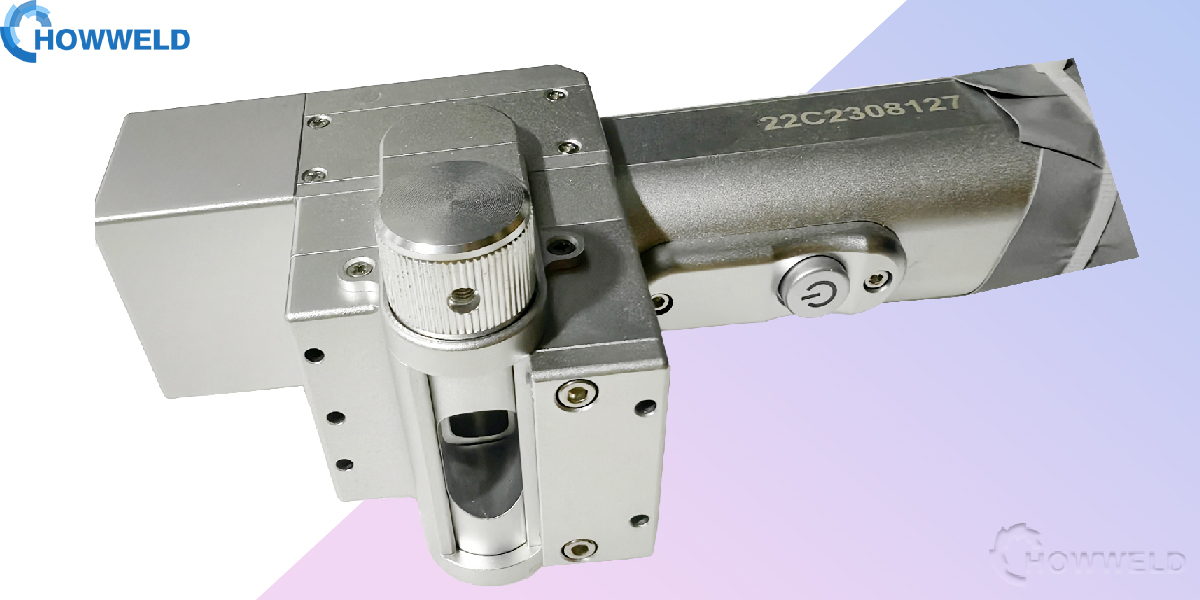

2. Cleaning head

3. Water chiller

4. Control system

What products suitable to use laser cleaning machine?

What products suitable to use laser cleaning machine?

Metal rust on surface of metal products,mold surface, tire mold surface, rubber mould surface, car engine.

Laser cleaning equipment is a new generation of high-tech products for surface cleaning. Easy to install, operate and automate. The utility model has the advantages of simple operation, no chemical reagent, no medium, no dust and no water when the equipment is turned on, automatic focusing, surface fitting cleaning and high surface cleanliness, and can remove the resin, oil stain, stain, dirt, rust, coating, coating and paint on the surface of the object.

Removal of old aircraft paint:

In Europe, laser cleaning systems have long been used in the aviation industry. The surface of the aircraft must be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. The traditional mechanical paint removal method can easily damage the metal surface of the aircraft and bring hidden dangers to safe flight. If multiple laser cleaning systems are used, the paint on the surface of an Airbus can be completely removed within two days without damaging the metal surface.

Specification Sheet

Specification Sheet

|

Laser Power |

1000W |

1500W |

2000W |

3000W |

|

Laser Wavelength |

1080±5 nm |

|||

|

Power adjustment range(%) |

10~100% |

|||

|

Scanning width |

10~300mm |

|||

|

Scanning head to product distance |

500mm |

|||

|

Laser cleaning head weight |

1.5kg |

|||

|

Max pulse energy(mj) |

No pulse energy |

|||

|

Cooling Way |

Water Cooling |

|||

|

Working Temperature |

5-35°C |

|||

|

Power Supply |

220V.50Hz |

220V.50Hz |

380V.50Hz |

|

|

Machine power consumption |

2.0KW |

3.0KW |

4.5KW |

5.5KW |

|

Options |

Portable/ Automation/Robot system |

|||

|

Length of optical fiber cable |

10 Meters [Maximum] |

|||

At the same time, laser cleaning has the advantages of high efficiency, less time and low cost. Although the one-time investment in the purchase of laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time and has low operation cost.

More importantly, it can easily realize automatic operation.

Machine Disadvantage:

1. Machine cost high

Machine Disadvantage:

1. Machine cost high

2. High energy consumption: Laser cleaning equipment requires high energy consumption, which may result in higher operating costs.

3. Multiple restrictions: Laser cleaning equipment requires certain environmental conditions, such as high air cleanliness and temperature requirements.

4. Application field limitations: The application field of laser cleaning equipment is relatively limited, suitable for harder surface materials, and may not be effective for soft, fragile, high reflective materials, etc.

The disadvantage of laser cleaning machines is that their development speed is not fast enough. At present, it has not yet covered the entire range of industrial cleaning, and the industrial fields with large-scale applications are mainly concentrated in the mid-range markets such as molds and metal materials.

In some low-end markets where manual polishing, angle grinders, wire brushes, and scrapers are used to remove paint and rust, laser cleaning machines appear too bulky. Currently, the smallest laser cleaning machine on the market is the size of a suitcase, and the world‘s smallest laser head is as large as a mobile phone. It can basically meet the needs of manufacturers, but further improvement is still needed compared to traditional tools.

In the high-end cleaning market, such as the paint removal work for ship overhaul, although many shipyards have proposed using laser cleaning, the current laser cleaning is not as efficient as traditional methods such as chemical cleaning and high-pressure water cleaning, and cannot meet the requirements of shipyards

But the iteration of technology is rapid

The first laser cleaning machine in China was only introduced in 2016;

In 2018, domestic laser cleaning machines were still at the hundred watt level;

In 2020, fiber laser technology surpassed 1000W;

The power of domestically produced fiber lasers for cleaning will only exceed 3000W in 2022

Last year, Howweld teamed up with Raycus MAX IPG laser to break through the technology of 6000W laser cleaning equipment, and now we can achieve 8000W composite laser cleaning. I believe that industrial cleaning covering the entire power range will be within 3 years.