Laser mold repair welding machine is a kind of laser welding machine.The special welding wire is melted to the damaged part of the mold through the high heat energy generated by the laser,and it is firmly welded to the mold body.

After laser welding,then grind it into a smooth surface.

Laser welding/repairing effective repair blisters,cracks,chipped corners,worn mold edges and sealing edges.

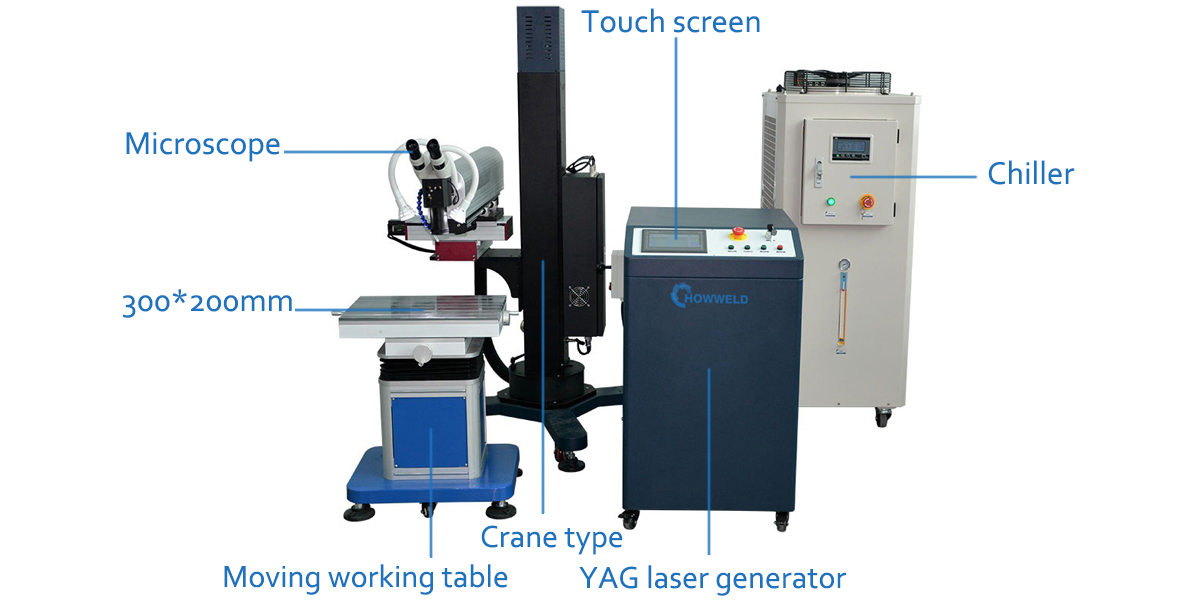

Spot laser welding machine configuration:

| Laser source | YAG laser source |

| Aim at positioning | Microscope |

| Crane arm | Heavy lifting and movable type |

| Laser head | Welding head with lens |

| Cooling system | Water cooling system |

Technical specifications:

| Model | HW-CT-400W |

| Max. output power | 400W |

| Max energy pulse | 100J |

| Laser wavelength | 1064nm |

| Pump source | Double xenon lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | 1~100Hz |

| Aiming and positioning | Microscope and camera system |

| Power Supply | 220VAC ± 5% / 50HZ |

| Power Consumption | 6KW |

| Cooling system | Water cooling |

| Weight | 460kg |

| Size | 1200*1200*1750mm |

| Hazard Class | 4 Class |

The laser mold welding machine is tailor-made for the mold industry, introducing German technology and adopting a unique structural design, suitable for repairing various large, medium, and small molds. Howweld team choose cheap laser source which install YAG laser, long time service.

1. Adopting a ceramic spotlight cavity imported from the UK, it is corrosion-resistant, heat-resistant, and has a lifespan of 8-10 years. The xenon lamp has a lifespan of over 8 million cycles.

2. The laser mold welding machine adopts the world‘s most advanced automatic shading system, eliminating eye irritation during operation.

3. The laser head can rotate 360 degrees, and the entire optical path can rotate 360 degrees. It also has electric lifting and pushing capabilities, making it particularly suitable for repairing various large, medium, and small molds.

4. Parameter adjustment is controlled by an intelligent remote control, which is easy and fast to operate.

5. The workbench can be electrically lifted and moved in three dimensions.

6. Electric adjustment of spot size.

Advantages:

1.Welding spot diameter control by 0.2~0.5mm.

2.The ceramic condensing cavity more than 8 million times.

3.Laser head can rotate 360 degrees.

4.Large penetration and firmly weld.

3.Laser head can rotate 360 degrees.

4.Large penetration and firmly weld.

Applicable materials and industries:

Suitable for repairing small,medium and large size molds.

Cold working high alloy steel,hot forging high alloy steel,nickel containing tool steel,high-grade steel,copper alloy,beryllium copper,high toughness aluminum alloy and other metal materials.

Suitable for repairing small,medium and large size molds.

Cold working high alloy steel,hot forging high alloy steel,nickel containing tool steel,high-grade steel,copper alloy,beryllium copper,high toughness aluminum alloy and other metal materials.