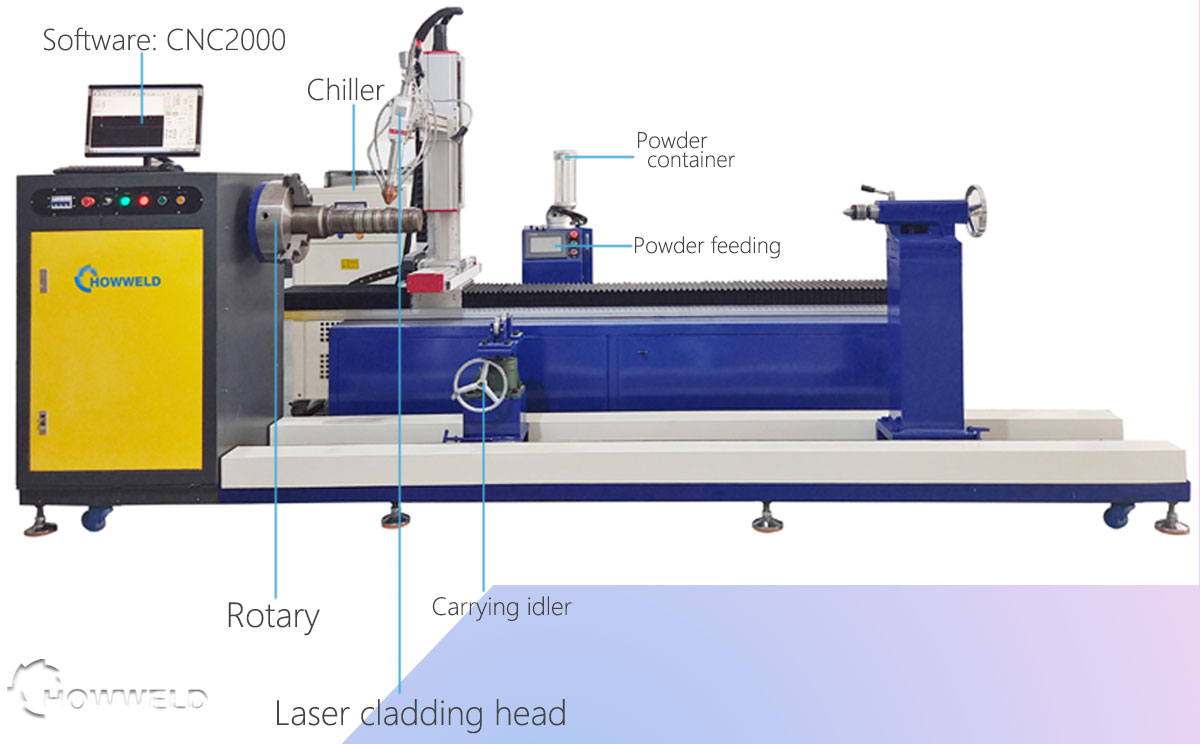

Laser cladding system

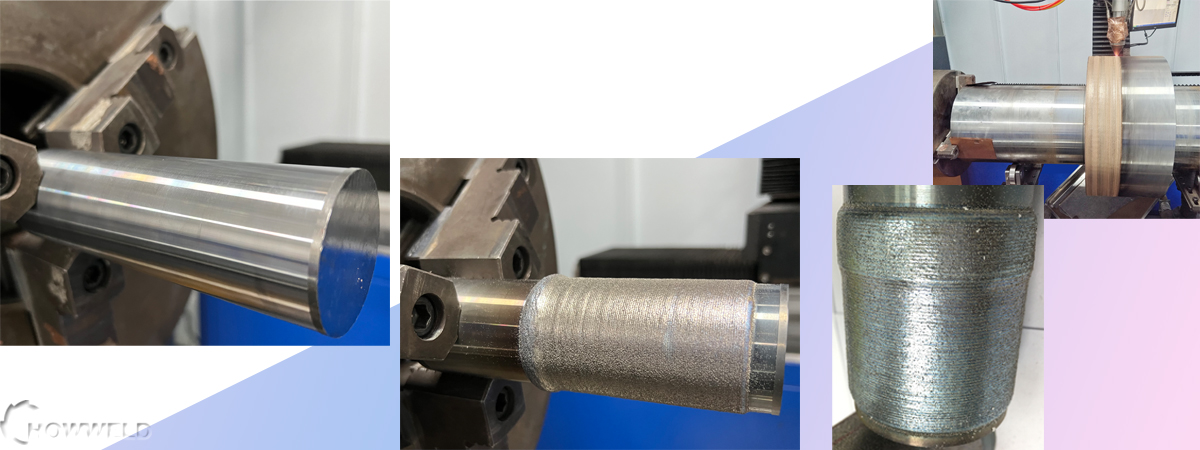

Laser cladding technology, as a new method for local surface treatment, has undergone decades of development and has gradually entered practical industrial applications from the laboratory. It has been widely used in industries such as coal mine equipment repair, motor rotors, bearings, and stern shaft repair in nuclear power, as well as in metallurgy, coal mining, petrochemicals, transportation, and nuclear power. Laser cladding for remanufacturing and repair bear surface damaged.

Laser Cladding, also known as laser overlapping welding or laser cladding, is a new surface modification technology. By adding a cladding material to the surface of the base material and fusing it with the thin layer on the surface of the base material by using a laser beam with high energy density, an additive cladding layer is formed on the surface of the base layer.

Repair of turbine shaft position

Wear and corrosion resistant cladding

Rust proof, wear-resistant and corrosion resistant cladding

Repair of bearing position

High speed cladding

.jpg)

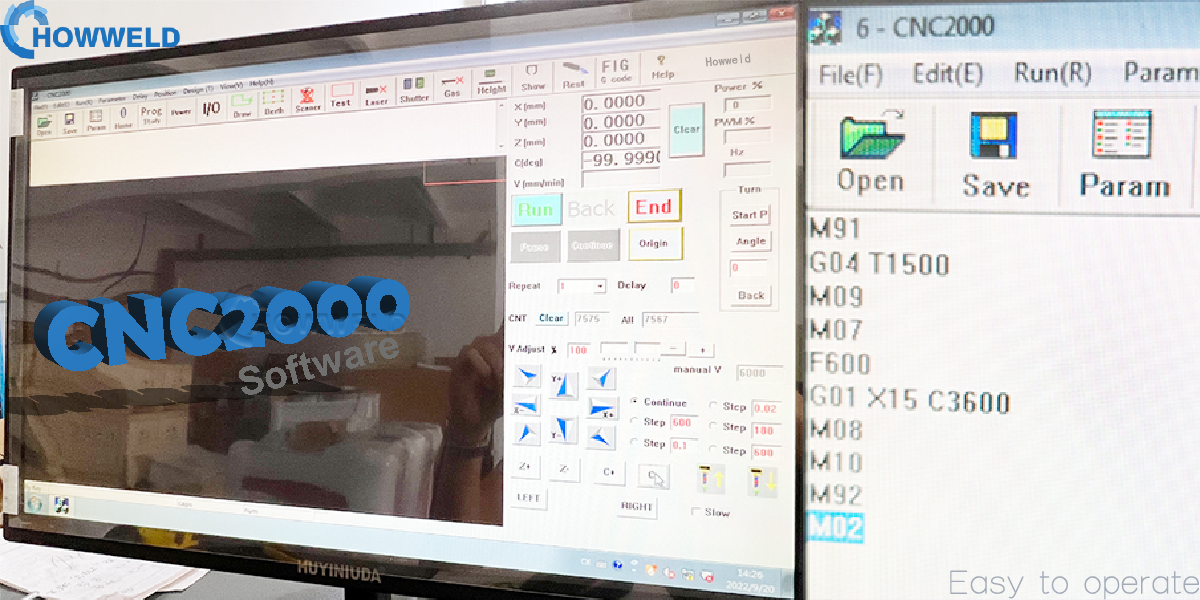

CNC2000 Control Software

.jpg)

CNC2000 Control Software

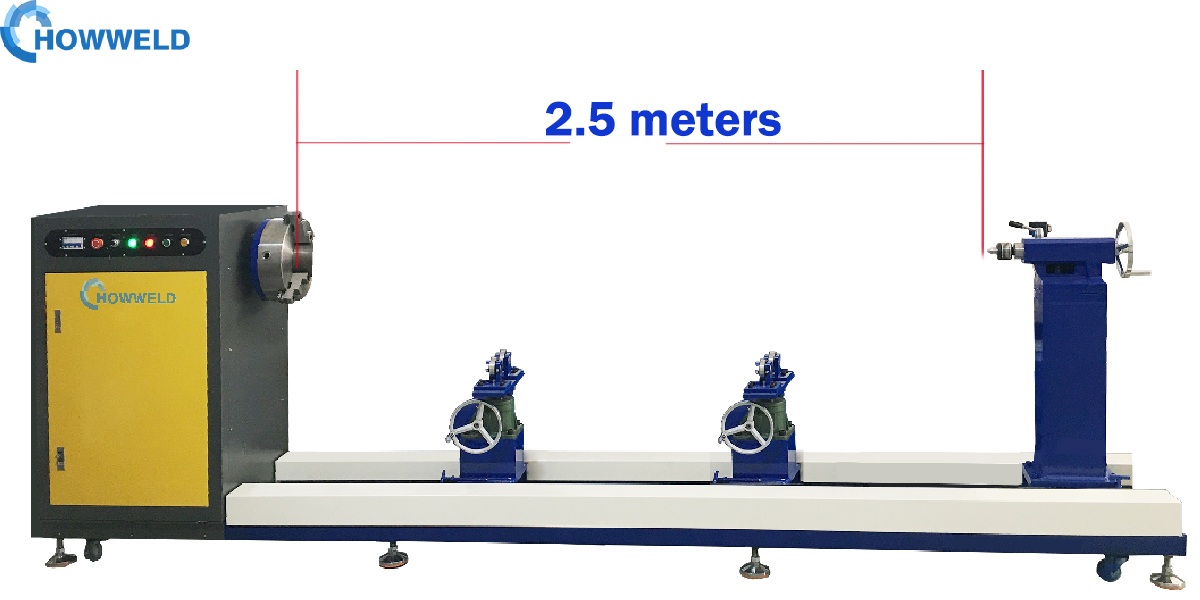

Working station

Optional: 1meter, 2 meter, 2.5 meter, 3 meter, 6 meter

Application

1. Metal surface repair

2. Automobile manufacturing

3. Mould industry

4. Petroleum equipment

5. Aviation manufacturing

6. Railway equipment

7. Spray barrel repairing

Main configurations

| Description | Model |

| Fiber laser source | Continuous type 3000W 6000W 8000W |

| Laser cladding head | Circular spot 3mm 4mm 6mm |

| Water cooling system | Capacity 12KW |

| Rotating platform | Motor 9kw, X Y Z Axis 4.5*0.5*0.5 meter |

| Control system | CNC3000 |

| Powder feeder system | Single barrel powder feeder optional double barrel |

| Power supply | 380V, 50Hz/60Hz |

| X Y Z Rail | Hiwin brand |

| Voltage pressure regulator | Match for 6KW machine |

Powder feeder

We have developed the third generation scraper type accurate powder feeder.

The powder feeder has the advantages of excellent manufacture, good powder feeding continuity, high precision, simple structure (only one independent moving part) and long service life.

It is especially suitable for laser cladding equipment.

| Description | Parameters |

| Powder feeding (g/min) | 1~40 |

| Powder feeding accuracy (%) | 1% |

| Capacity of powder storage tank (kg) | 10~50 |

| Particle size (mesh) | 80~550 |

| Powder gas flow (m3/h) | 0.1~0.4 |

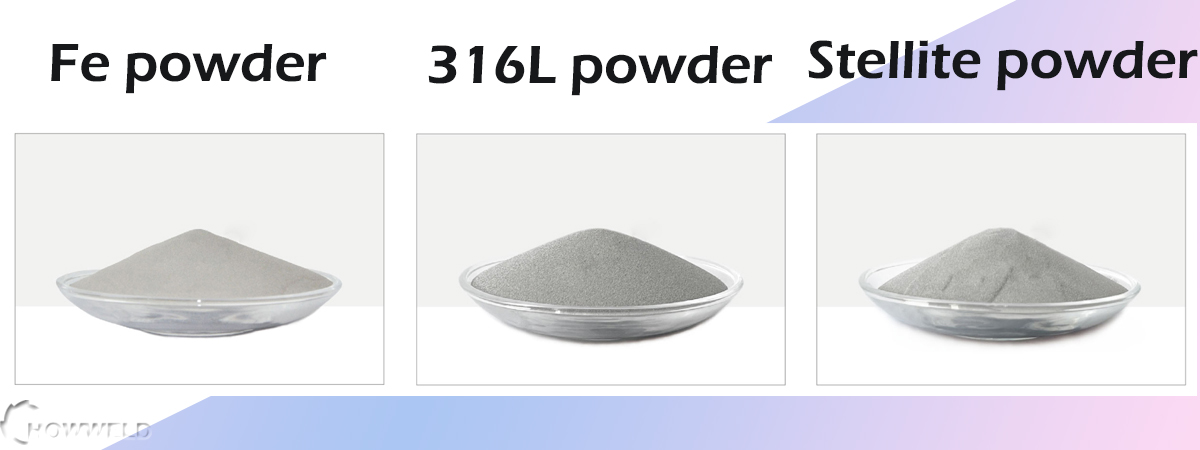

Metal Based Powders

Samples

.jpg)

.jpg)

Certificate CE

Key words: Repair of turbine shaft position, Laser cladding, Wear and corrosion resistant cladding

Rust proof, wear-resistant and corrosion resistant cladding, Repair of bearing position, High speed cladding