Container body handheld laser welding solution

Time:2024-01-19

Views:531

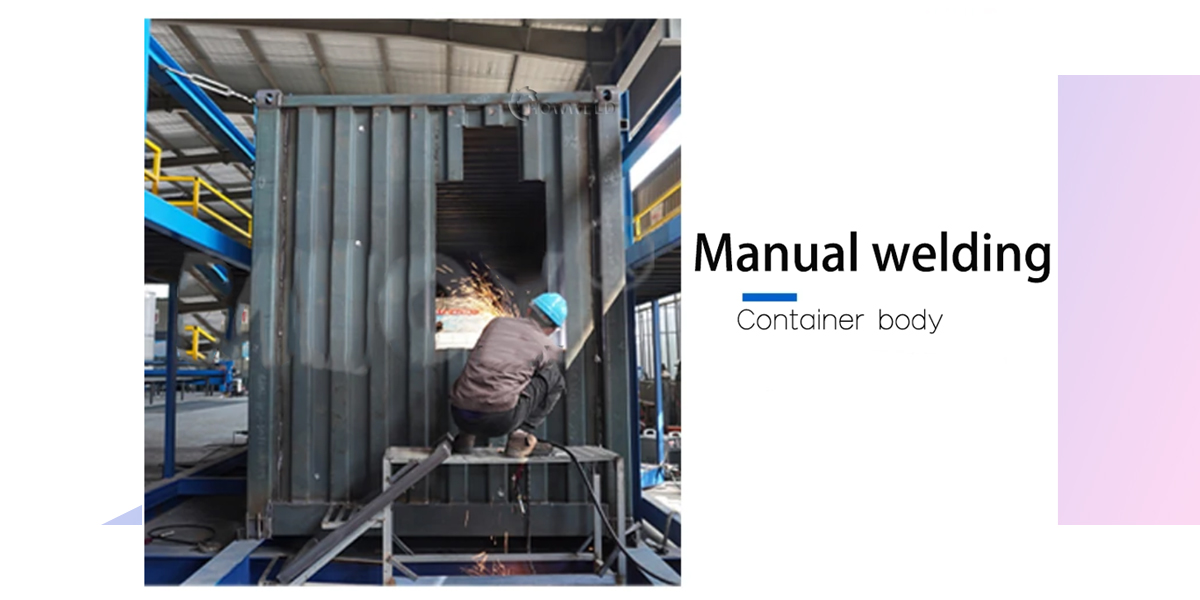

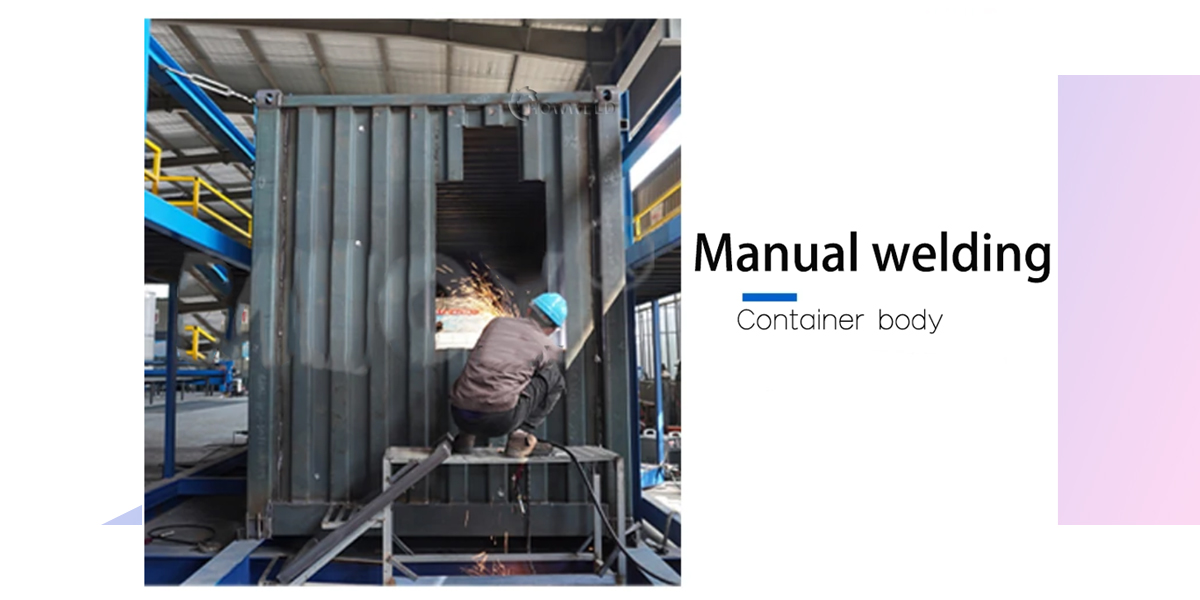

Container body welding

Welding machine:

The laser welding microstructure and properties of steel SPAH for 2-4mm containers were studied using a 3000w hand-held laser welder.

The results show that the most suitable welding laser power is 3kw, and the fusion zone and overheat zone are both bainite; The normalized zone consists of bainite and a small amount of ferrite; The highest hardness is in the overheated zone, at 306HV0.2, which is about 50% higher than the base material.

Container body materials:

Spah is a high-quality steel commonly considered as a low-carbon or medium carbon steel, which has good strength, toughness, and wear resistance. This type of steel is mainly used for manufacturing various mechanical parts, automotive parts, building structures, etc.

The main components of Spah steel are iron, carbon, and other alloying elements, with carbon content typically ranging from 0.1% to 0.3%. The strength of this type of steel mainly comes from its carbon content and the addition of other alloying elements, which can increase the hardness and strength of the steel.

In addition to its high strength, Spah steel also has good toughness, which makes it have great application prospects in manufacturing various mechanical and automotive parts. Meanwhile, Spah steel also has good wear resistance and can be used to manufacture various wear-resistant parts and tools.

During the manufacturing process, Spah steel typically requires processes such as heat treatment and surface treatment to improve its hardness and wear resistance. In addition, Spah steel can also be used for welding and processing operations, which makes it have good machinability and weldability when manufacturing various mechanical and automotive parts.

Spah is a high-quality steel with good strength, toughness, and wear resistance, which can be used to manufacture various mechanical parts, automotive parts, building structures, etc.

Standard container thickness:

The standard container thickness refers to the thickness of the steel plate in the container, usually measured in millimeters (mm). The thickness of a standard container directly affects its load-bearing capacity and service life. Therefore, in the container manufacturing process, manufacturers will choose steel plates of different thicknesses according to different needs and uses.

At present, the commonly used standard container thicknesses internationally are 4mm, 5mm, 6mm, 8mm, and 10mm. Among them, 4mm thick containers are mainly used for the transportation of light goods, such as textiles, shoes, toys, etc. 5mm and 6mm thick containers are suitable for the transportation of medium-sized goods, such as mechanical equipment, electronic products, chemicals, etc. 8mm and 10mm thick containers are suitable for the transportation of heavy goods, such as steel, cement, ores, etc.

In addition to the load-bearing capacity and service life of containers, the thickness of standard containers is also related to their weight and cost. Generally speaking, the heavier the container, the higher the cost. Therefore, when choosing a container, it is necessary to choose the appropriate thickness based on actual needs and the weight of the transported items.

In addition, the thickness of standard containers is also related to their anti-theft performance. The thicker the container, the better its anti-theft performance, as thieves find it difficult to damage thicker containers with ordinary tools. Therefore, when transporting valuable items, choosing thicker containers can improve the safety of the goods.

In summary, the thickness of a standard container is an important factor affecting its load-bearing capacity, service life, weight, cost, and anti-theft performance. When selecting containers, it is necessary to choose the appropriate thickness based on actual needs and the weight of the transported items to ensure the safety of the goods and smooth transportation.

Brief introdution:

Container body

Materials:

4mm steel

SPAH for 2-4mm containers

4mm steel

SPAH for 2-4mm containers

Test manual welding:

Test time: 2023.12.12

Samples from: Chinese

Welding requirements: Welding firmness

Laser resonator: Raycus 3000w

Test factory: Howweld