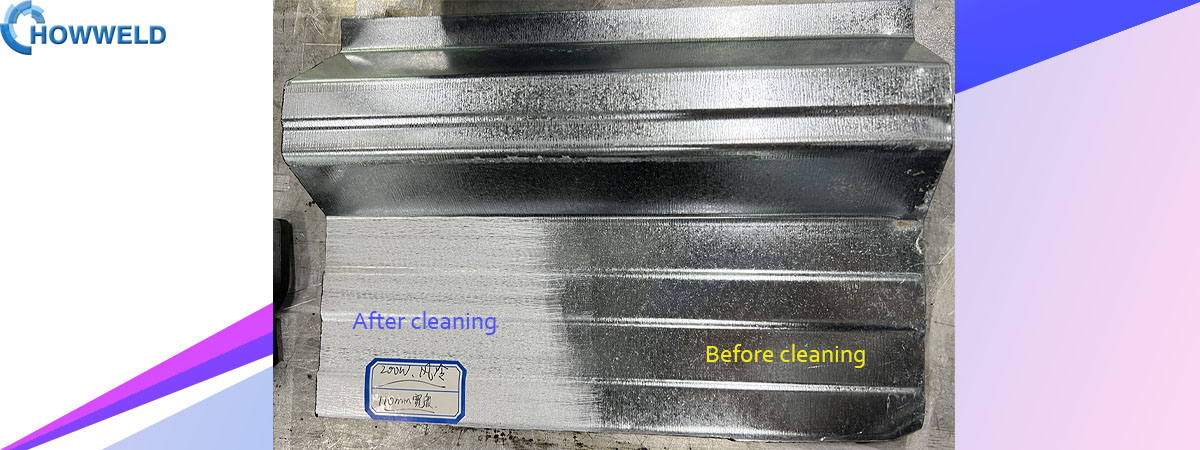

Galvanized sheet surface cleaning by pulse laser before painting

Time:2023-05-13

Views:692

Pulse Laser Increase surface roughness

Laser rust removal equipment is a high-tech product that represents new surface cleaning. It has the characteristics of no grinding, non-contact, no thermal effect, green, and is suitable for various materials.

It not only solves problems that traditional cleaning methods such as acid pickling and phosphating, sandblasting rust removal, high-frequency ultrasonic cleaning, etc. cannot solve, but also is more efficient and safe.

Easy to operate, turn on the power, turn on the device, manually set parameters on the screen, and click Start to perform cleaning without chemical reagents, media, dust, or water. It can automatically focus on and fit the curved surface, resulting in high cleanliness of the cleaning surface.

The beam emitted by the laser rust removal machine is absorbed by the pollution layer on the surface to be treated, and generates shock waves, causing pollutants such as rust to become debris and be removed. Laser rust removal equipment can easily remove surface resins, oil stains, stains, dirt, rust, coatings, coatings, paints, etc. from objects.

Laser rust removal machine uses the principle of laser cleaning to clean the rust layer on the metal surface. Compared to traditional rust removal processes, laser rust removal not only improves the oxidation resistance of the substrate but also further improves the surface roughness. As long as the laser parameters are set accurately, it can also achieve no damage to the substrate.

During the laser rust removal process, the higher the laser energy density, the higher the temperature. As the density increases, the energy density in the cleaning operation must be greater than the cleaning threshold (reaching the rust removal effect threshold) and less than the damage threshold (reaching the damage substrate threshold), in order to achieve a cleaning effect that does not damage the substrate.

In addition to increasing oxidation resistance, the laser rust removal process can also improve the roughness of the metal surface.

The principle is as follows: when the laser energy density is higher than the damage threshold, the temperature of the metal surface exceeds the melting point, and the metal surface will form a dense molten pool.

After a short period of cooling, a rough surface will be formed, which is of great significance in the renovation operation of repeated coating and repainting.

It can be completed during the process of rust and paint removal, reducing workload. Of course, it is also possible to work alone, simply increasing the roughness of the metal surface.

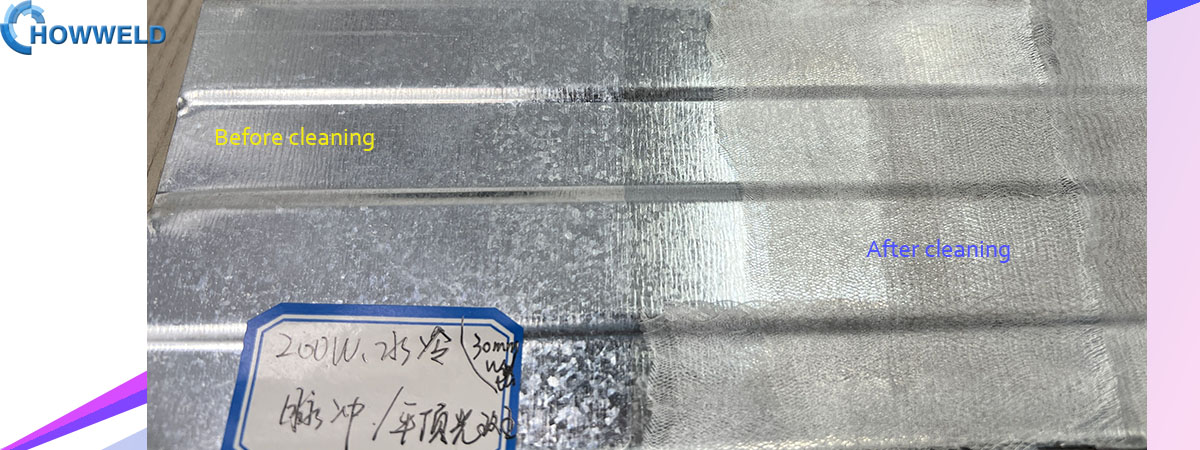

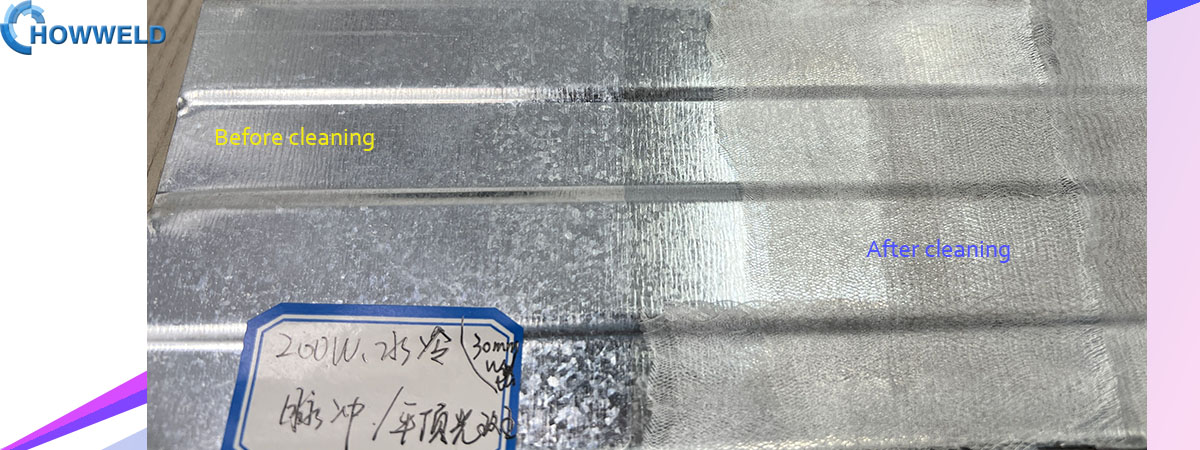

Test sample

Keywords: pulse laser cleaning machine price, oxide layer removal, higher efficiency laser cleaning, galvanized sheet surface treatment pulse laser cleaning

pulse laser beam, increase roughness

Test sample

Test time: 2023.5

Samples from: Europe

Cleaning requirements: clean surface, reduced brightness, increase roughness

Machine power: 200W laser power, full 100% power, pulse laser beam

Test team: Howweld

Parameters of laser:

Laser power: 100% of 200W power

Scanning width: 2mm

Scanning length: 50mm

Scanning speed: 5200

Laser frequency: 150KHz

Laser type: pulse

Scanning mode: Spiral Mode, straight line

Focus lenses: F160

Scanning number of times: 2

Scanning distance: 180mm

More videos please follow us:

https://www.youtube.com/channel/UCxkr1yArgON3qM1-HdunoXQ

Above content writed by Howweld Team that we provide laser processing equipment with service, provide suitable laser welding, laser cleaning solution. Contact email: info@howweld.com

https://www.youtube.com/channel/UCxkr1yArgON3qM1-HdunoXQ

Above content writed by Howweld Team that we provide laser processing equipment with service, provide suitable laser welding, laser cleaning solution. Contact email: info@howweld.com

Welcome to inquire, visit and testing samples. We are looking forward to your presence.

Keywords: pulse laser cleaning machine price, oxide layer removal, higher efficiency laser cleaning, galvanized sheet surface treatment pulse laser cleaning

pulse laser beam, increase roughness