Oxide layer removed by pulse laser cleaning machine

Time:2023-04-21

Views:701

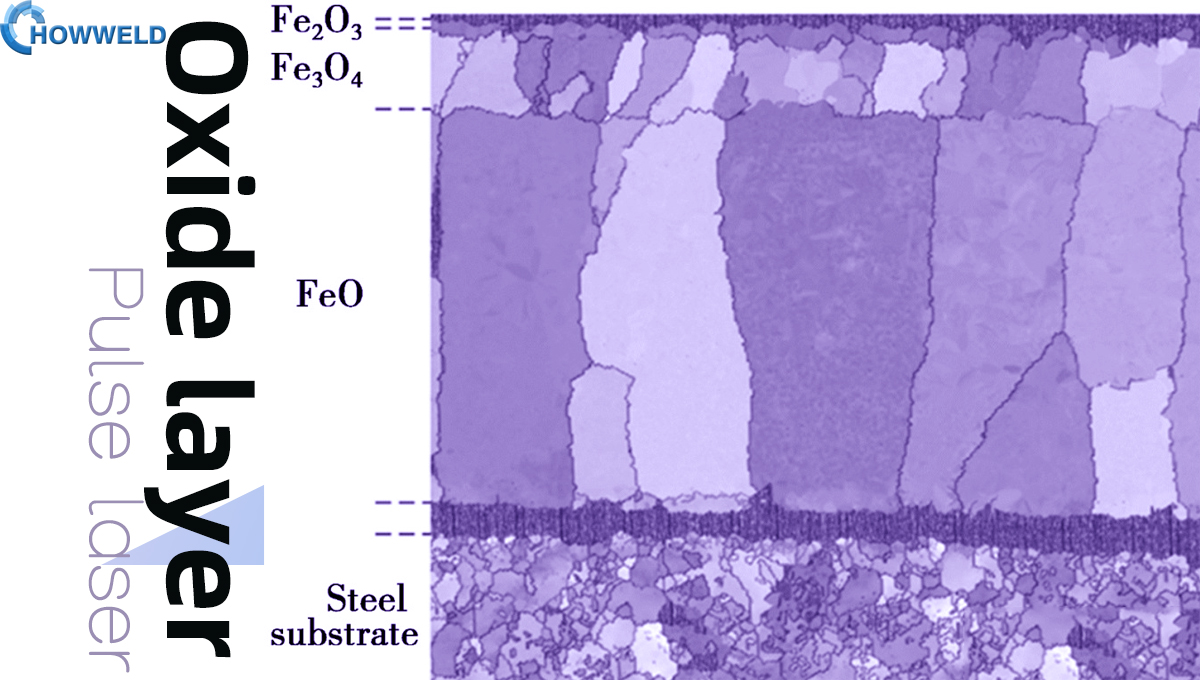

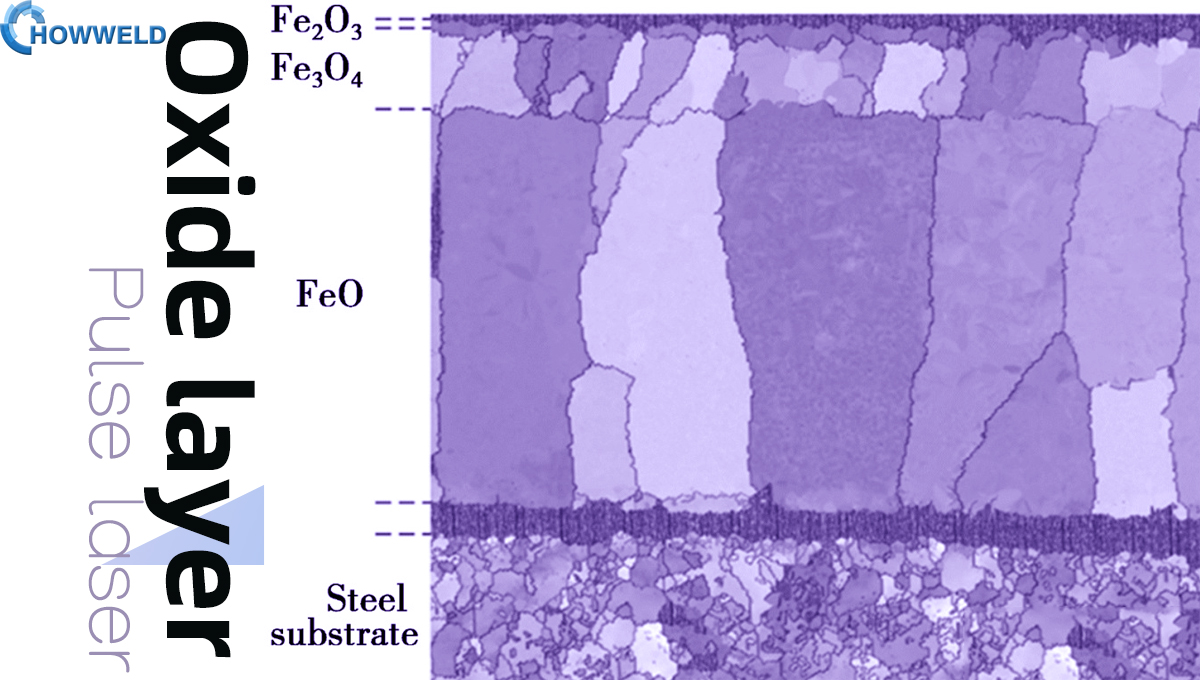

Metal surface layer-Oxide layer

Oxide film-iron oxide scale is formed on the metal surface layer as a result of oxidation, and due to the diffusion of oxygen and iron during heating, iron oxide scale is formed as a result. Iron diffuses towards the surface layer, while oxygen, on the contrary, diffuses through the thin layer (film) with iron oxide scale into the metal, so the iron oxide scale layer becomes thicker.

Oxide film-iron oxide scale is formed on the metal surface layer as a result of oxidation, and due to the diffusion of oxygen and iron during heating, iron oxide scale is formed as a result. Iron diffuses towards the surface layer, while oxygen, on the contrary, diffuses through the thin layer (film) with iron oxide scale into the metal, so the iron oxide scale layer becomes thicker.

So, what factors determine the formation of oxide scale? According to relevant data, the formation of oxide scale increases with the increase of heating time, and the heating is related to the physical properties of oxides, and porous oxides are not easy to adhere to. , and cannot resist the diffusion of oxygen into the depths of the scriptures.

On the contrary, oxides with a dense structure are strongly attached to the metal surface, and can well address the diffusion of oxygen to the depth of the metal

That is to say, the amount of oxide scale on the surface of steel damage has a certain relationship with the alloy composition of steel damage. Some materials have surface oxide scales that are well treated and have little secondary oxidation, while some materials have surface oxide scales that are treated quickly.

However, the secondary oxidation speed is also very fast. The best way to choose scale treatment is the ultra-high pressure oxidation film machine that appears on the market. It uses the mechanical impact of high-pressure water to remove scale (high-pressure water phosphorus removal) is also The most common and effective way at present.

Howweld uses pulsed laser to clean six times more efficiently.

High-temperature oxide layer

Pulse laser cleaning system

Pulse laser cleaning, as a pollution-free, consumable, and full-chain visual and controllable industrial cleaning method, shines in the processing and application of various fields such as rust removal, paint removal, mold and metal surface technology, and has become the industry of manufacturing enterprises. The perfect choice for structural upgrades. But even in the good situation of the domestic laser cleaning industry, there are still a few "blockers" to be overcome, and the cleaning of high-temperature oxide layer is one of them that is quite stubborn.

Technological breakthrough

Test machine: 300w pulse laser, 500w pulse laser

Test time: 2023.4.21

Base materials: Aluminum sheets

Surface material: oxide layer

Test parameters:

Power: 50% of 500w power machine

Focus lenses: F160

Pulse frequency: 25KHz

Pulse width: 130ns

Galvanometer speed: 460mm/s

Scanning number of times: 1

Scanning distance: 180mm

Cleaning efficiency: 12.86 square meter/hour

Chemical agent solution to clean the oxide layer

High-temperature oxide layer

High-temperature oxide layer refers to a kind of metal corrosion caused by the reaction of metal materials and oxygen to form oxides at high temperatures. High-temperature oxidation in a broad sense includes sulfidation, halogenation, nitriding, carbonization, etc., and widely occurs in the preparation process of various industrial metals such as steel, titanium, and aluminum. In the practice of laser cleaning, Howweld researchers concluded that, different from ordinary oxide layers, high-temperature oxide layers have three difficulties in the laser cleaning process:

The thickness of the general oxide layer is only tens of nanometers, while the thickness unit of the high-temperature oxide layer is micron, which is thousands of times that of the ordinary oxide layer. Correspondingly, the cleaning efficiency will be greatly reduced.

Different from foreign matter such as paint and glue attached to the surface of the base material, the high-temperature oxide layer is a metal substrate that has a higher concentration of oxygen defects formed inside the metal body, which promotes the diffusion of atoms, resulting in a substantial increase in the density of the oxide layer. the material itself.

In this case, when the oxygen and carbon atoms infiltrate the surface of the metal, they bond stronger, making it harder to clean.

The principle of laser cleaning is complex, including ablation, decomposition, ionization, degradation, melting, combustion, gasification, vibration, explosion, peeling and other physical and chemical changes on the surface of the material.

The high-temperature oxide layer has a stronger resistance to high temperature, which makes it more difficult for laser cleaning to work based on the ablation and gasification mechanism.

Pulse laser cleaning system

Pulse laser cleaning, as a pollution-free, consumable, and full-chain visual and controllable industrial cleaning method, shines in the processing and application of various fields such as rust removal, paint removal, mold and metal surface technology, and has become the industry of manufacturing enterprises. The perfect choice for structural upgrades. But even in the good situation of the domestic laser cleaning industry, there are still a few "blockers" to be overcome, and the cleaning of high-temperature oxide layer is one of them that is quite stubborn.

Technological breakthrough

Test machine: 300w pulse laser, 500w pulse laser

Test time: 2023.4.21

Base materials: Aluminum sheets

Surface material: oxide layer

Test parameters:

Power: 50% of 500w power machine

Focus lenses: F160

Pulse frequency: 25KHz

Pulse width: 130ns

Galvanometer speed: 460mm/s

Scanning number of times: 1

Scanning distance: 180mm

Cleaning efficiency: 12.86 square meter/hour

Chemical agent solution to clean the oxide layer

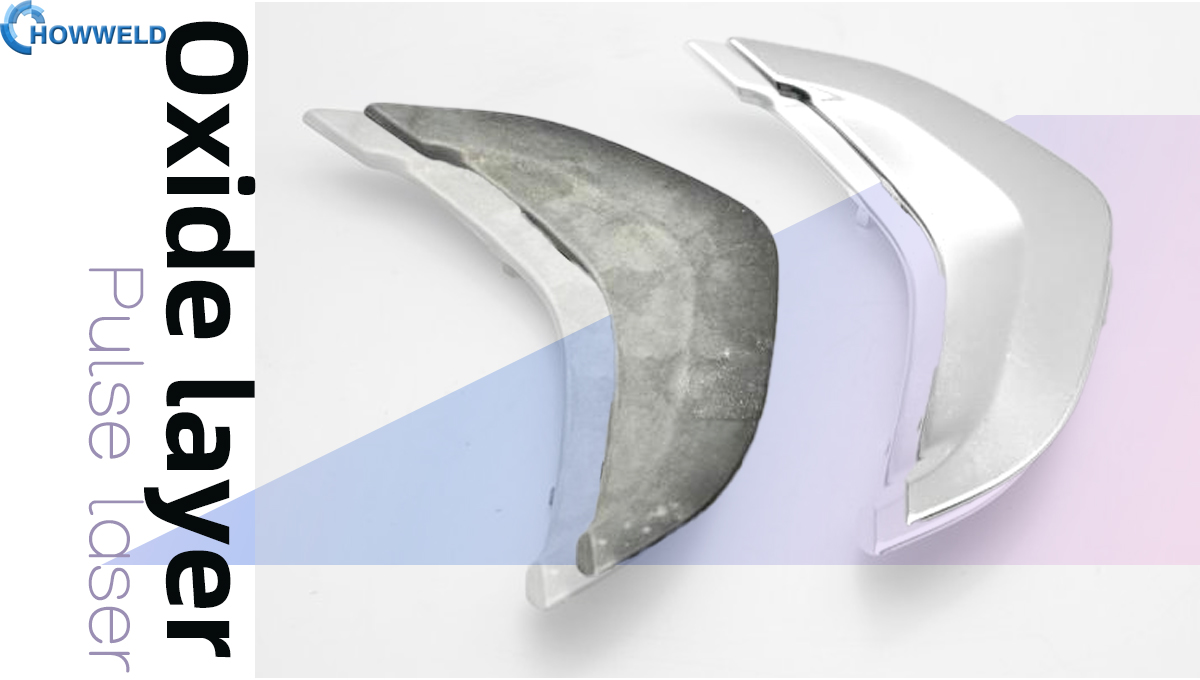

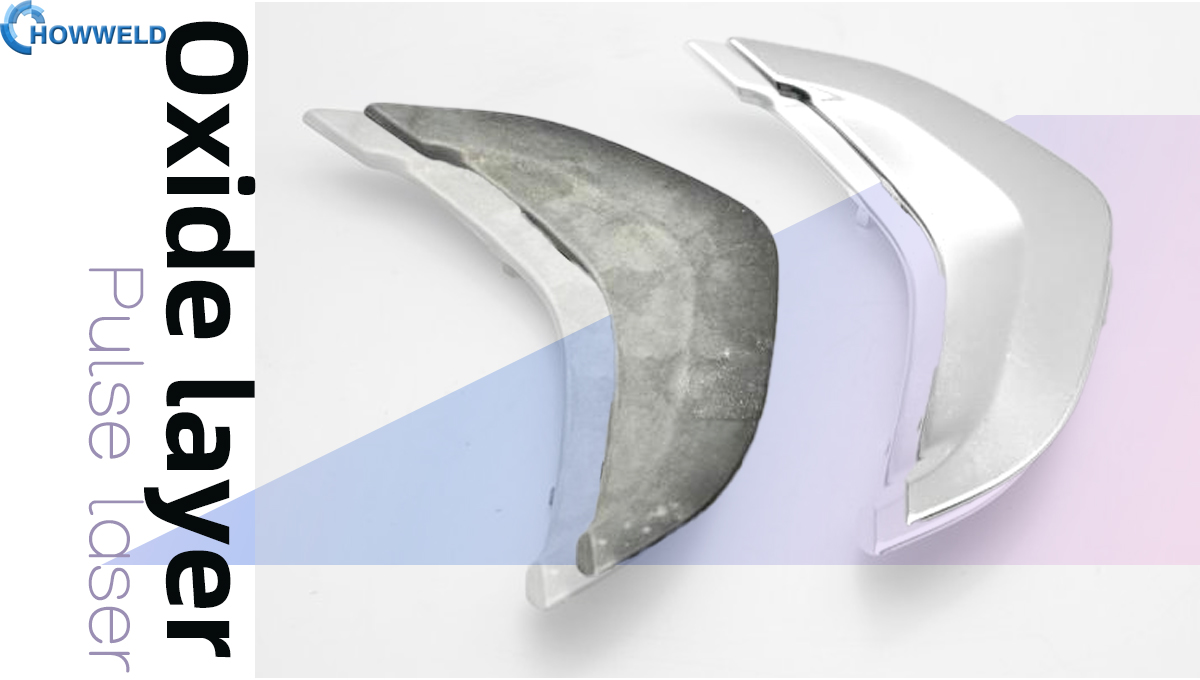

This is a difficult point that all companies engaged in research and development of laser cleaning technology in the industry are trying to overcome in recent years, because behind this difficulty is a huge market to replace the pickling process of domestic rolled sheet metal.

Pickling plate is the product of immersing the hot-rolled plate in a chemical solution such as sulfuric acid to remove oxides and other films on the metal surface. It is the pre-treatment or intermediate treatment of the rolled plate electroplating, enamel, rolling and other processes. It is widely used in the automobile industry, machinery industry, light industrial appliances and stamping parts of various shapes: such as girders, auxiliary beams, rims, spokes, car panels, fans, chemical oil drums, welded pipes, electrical cabinets, fences, iron ladder etc.

Pulse laser cleaning advantages

Pulse laser cleaning advantages

The pickling method requires chemical agents as consumables, so the unit cost is composed of equipment depreciation + consumable costs; laser cleaning does not require other consumables except for the purchase of equipment. The unit cost is the depreciation of the equipment; therefore, the larger the cleaning scale and the longer the service life, the lower the unit cost of laser cleaning.

The composition of the pickling production line requires a complex process, and the proportion of pickling agents for different metal materials is different. Therefore, the conversion production line requires a large conversion cost. The metal material to be cleaned in a short period of time is single and cannot be changed flexibly. There is no conversion cost for laser cleaning: the same cleaning machine can clean the steel plate one minute and clean the aluminum alloy the next minute after switching the software parameters. It is convenient for enterprises to implement JIT flexible production.

Keywords: pulse laser cleaning machine, oxide layer removal, higher efficiency laser cleaning

Above content writed by Howweld Team that we provide laser processing equipment with service, provide suitable laser welding, laser cleaning solution. Contact email: info@howweld.com

Welcome to inquire, visit and testing samples. We are looking forward to your presence.

Keywords: pulse laser cleaning machine, oxide layer removal, higher efficiency laser cleaning