Customized pulse laser cleaning system

Suitable for cleaning mesh rollers with a diameter of 50-200mm and a length of 100-1500mm

The automatic scheme adopts a dual axis platform as a whole, as well as a laser head with built-in focusing function.

Enter the corresponding parameters on the right screen, and the automatic adjustment end will move to the corresponding position. After placing the workpiece, the laser head will move from left to right, combined with two rollers to drive the workpiece to rotate, completing the cleaning of the outer surface of the workpiece.

Laser Textured Roller Cleaning System

_Howweld company_HWLAZER Brand

_Howweld company_HWLAZER Brand

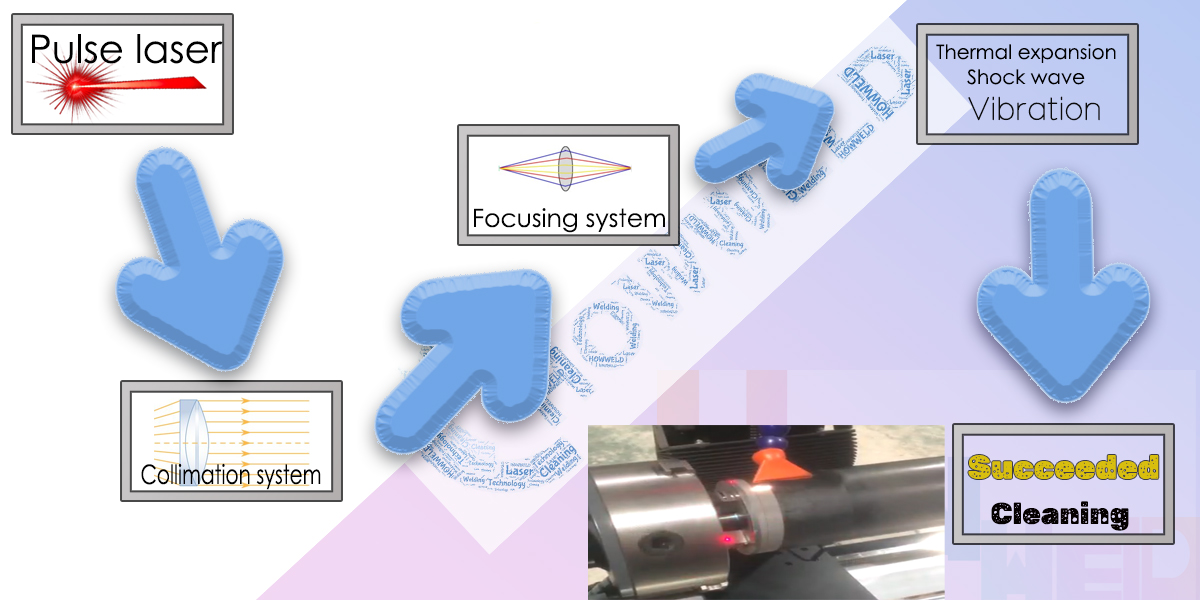

How it works: The anilox roller absorbs the energy of the laser beam, causing a high-intensity impact on its ceramic surface. This results in the so-called cold evaporation of various contaminants on the drum. A suction device is required to remove ink residue and other contaminants.

Sample display

Sample display