The work pieces are the least thermally stressed in laser cutting, because the heat is concentrated only on a very limited area of the workpiece due to the highly focused laser beam. Thereby only a short action time is required, which allows cutting at a high speed. In laser cutting almost any material can be machined (in addition to steel and leather, plastic, PVC, wood, glass, etc). With the method, the workpieces can be cut precisely with dimensional accuracy. Disadvantages of this method are a high energy consumption and high system procurement costs.

Precision Cutting:

Versatility:

Programming and Control:

High-Speed Processing:

Applications

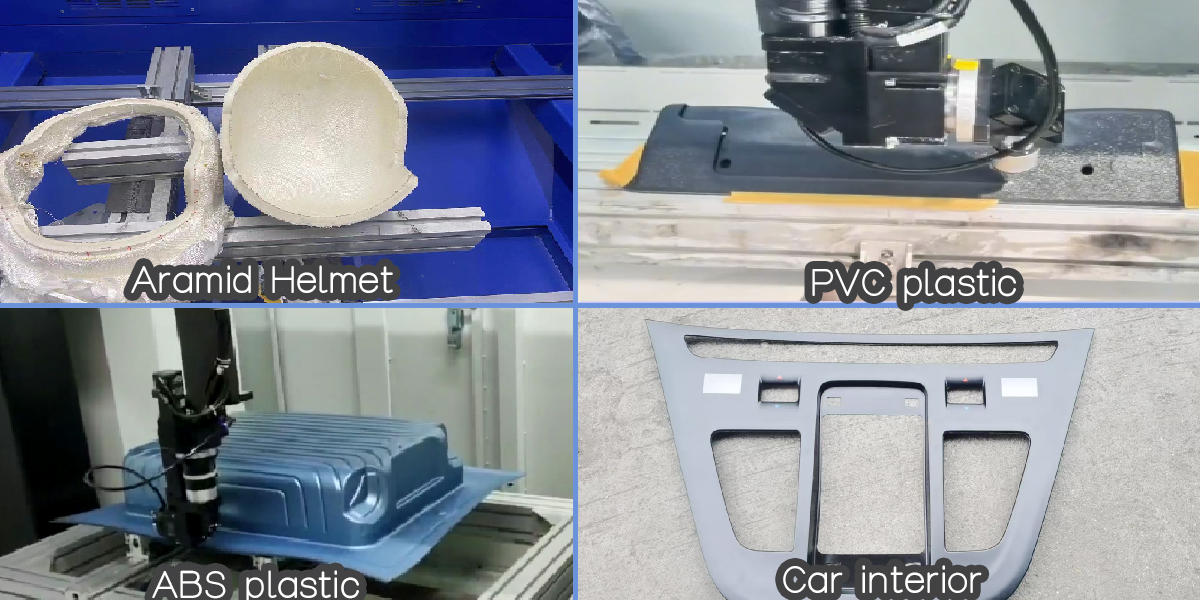

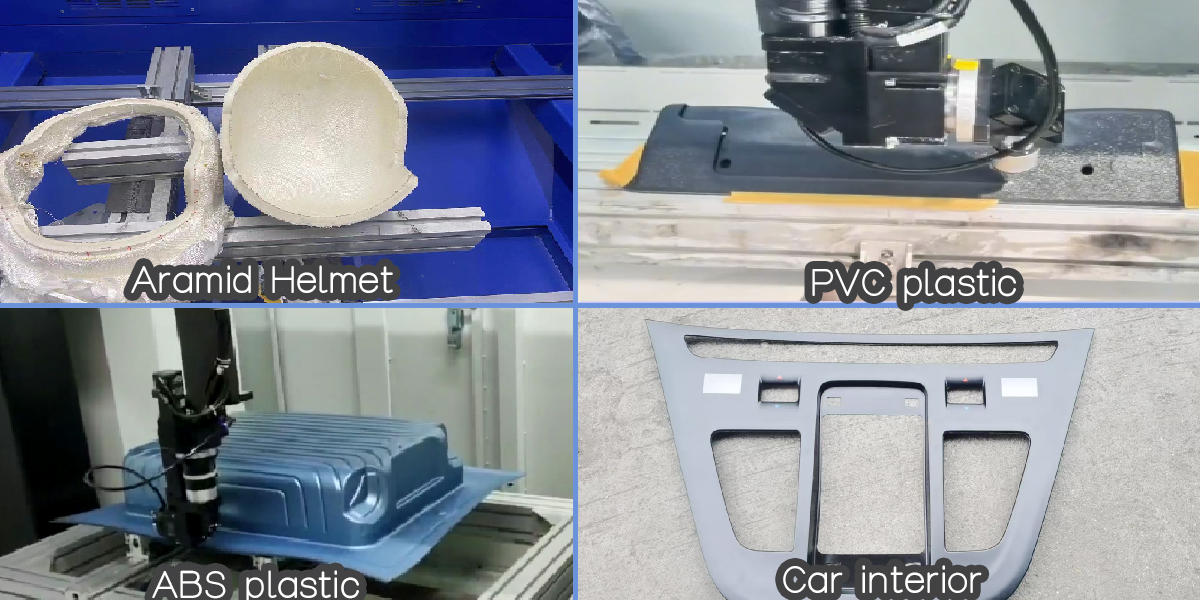

Laser cutting machines are mainly used for interior plastic parts in the automotive industry, plastic parts in the home appliance industry, cutting and digging holes in bicycle helmets, heels of shoes, blister toys, masks, automotive molds, trimming of automotive interiors, trimming of aluminum-plastic parts, trimming of plastic parts, trimming of blister parts, trimming of blister plexiglass (acrylic), PP, PA, PUR, PBT, PET, PE, TPU, ABS, PVC, PC, etc., as well as cutting of non-metallic materials for special-shaped parts.

Main configuration

A cutting system is a machine that is used for separating materials. Thereby a variety of materials, such as aluminium, tin, steel (even hardened steel), titanium, wood, ceramics or plastics, can be separated or cut in certain forms.

In cutting systems, one can distinguish between two different procedures: Abrasive cutting machines working with physico-chemical separation processes (laser, plasma and flame cutting) and metal-cutting machines that cut through the workpiece by means of a high pressure jet (water jet cutting).

A five-axis laser cutting machine is an advanced cutting tool used to precisely process three-dimensional (3D) components. Unlike traditional two-dimensional (2D) laser cutting machines, which operate on flat planes, a five-axis machine adds rotational and tilting axes, enabling cutting in complex geometries. This capability makes it indispensable in industries that require intricate designs and tight tolerances.

Features of Five-Axis Laser Cutting Machines

Axes of Motion:

X, Y, Z axes: Standard linear movements for positioning.

A-axis: Rotational movement around the X-axis.

B-axis: Tilting movement around the Y-axis. This combination allows for multi-directional cutting, essential for 3D structures.

Precision Cutting:

Extremely high accuracy, typically in micrometers, suitable for parts with intricate details or critical tolerances.

Capable of maintaining consistent performance across complex contours and angles.

Versatility:

Works with a wide range of materials, including metals (steel, aluminum, titanium), plastics, and composites.

Can handle flat sheets, tubular materials, and preformed 3D parts.

Programming and Control:

Powered by advanced CNC (Computer Numerical Control) systems.

Utilizes CAD/CAM software for creating precise cutting paths.

High-Speed Processing:

Integrates advanced lasers, such as fiber or CO₂ lasers, offering fast material removal rates and clean finishes.

Applications

Laser cutting machines are mainly used for interior plastic parts in the automotive industry, plastic parts in the home appliance industry, cutting and digging holes in bicycle helmets, heels of shoes, blister toys, masks, automotive molds, trimming of automotive interiors, trimming of aluminum-plastic parts, trimming of plastic parts, trimming of blister parts, trimming of blister plexiglass (acrylic), PP, PA, PUR, PBT, PET, PE, TPU, ABS, PVC, PC, etc., as well as cutting of non-metallic materials for special-shaped parts.

Main configuration

|

Fiber laser |

Carbon fiber cutting special laser MAX-2KW |

One set |

|

Software and the control system |

3 D laser map cutting control system (hand wheel, keyboard and mouse) |

One set |

|

XY Axis |

Precision wire rod, tooth rack electric sliding table |

Two sets |

|

Z Axis |

Precision wire rod module |

One set |

|

C Axis |

Precision-level hollow rotary table |

One set |

|

B Axis |

Precision rotating table |

One set |

|

Motor drive |

The Panasonic servo motor |

Five sets |

|

Chiller |

6000W power chiller |

One set |

|

High pressure air compressor |

Without oil/water, 0-16 KG pressure |

One set |

|

Cutting head |

Special 3 D cutting head for carbon fiber cutting |

One set |

|

Fan |

750W |

Three sets |

|

Working station |

Aluminum profiles (customer-provided smelting) |

One set |

Automotive interior plastic parts

Plastic parts for the home appliance industry, cutting and digging holes for bicycle helmets, shoe heels, vacuum formed toys, masks, and automotive molds

laser cutting aramid helmets #lasercutting #lasercuttingmachine