Principles of UV Laser Marking

The ultraviolet laser marking machine operates based on several key principles:

Laser Generation and Focusing: The laser generator produces ultraviolet light, which is then adjusted and focused by the beam expander and optical system. This process reduces the laser beam‘s diameter, thus increasing its energy density and strengthening its impact on the material.

Material Interactions: The interaction between the laser beam and materials occurs through three main mechanisms: photothermal, photochemical, and mechanical effects. Photothermal effects involve heating materials to create markings; photochemical effects trigger chemical reactions in materials by exciting electronic energy levels; and mechanical effects achieve markings through vaporization or ablation of the material.

Control System: The control system is crucial for the ultraviolet laser marking process. It manages parameters such as laser power, beam position, size, and shape, enabling precise control over the markings. The stability and accuracy of the control system directly impact the marking results.

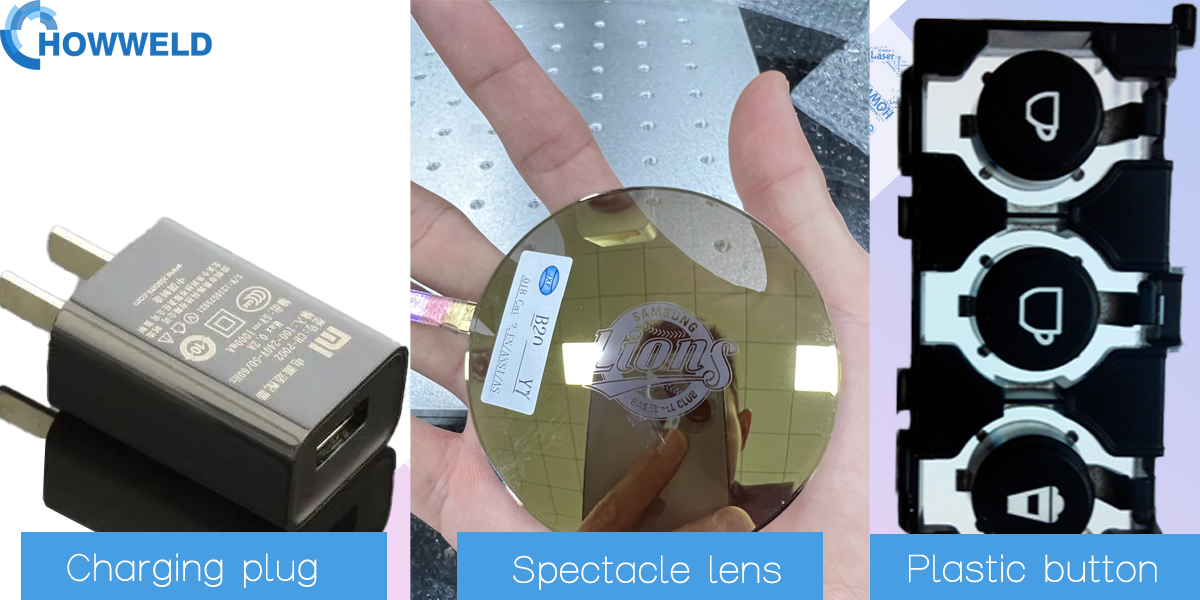

Applications: UV laser marking machines are extensively used for surface marking on packaging bottles made of cosmetics, pharmaceuticals, food, and other polymer materials; on flexible PCB boards for marking and cutting; in silicon wafer micro- and blind-hole drilling; and on LCD glass, glassware surfaces, metal coatings, plastic buttons, electronic components, communication devices, and building materials.

Characteristics

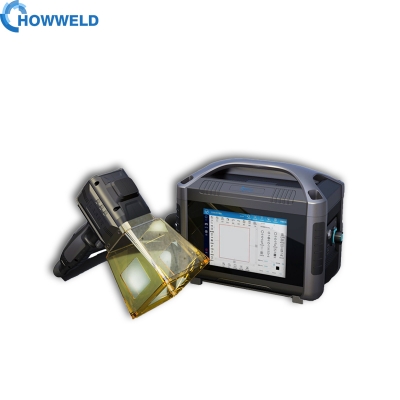

1. High efficiency in electrical / optical conversion, air cooling ;

2. Small in size, with high beam output quality, high reliability;

3. The marking speed is 3~12 times of first and second generation of laser markers;

4. No consumable ,10 years service life of the laser source,energy saving;

5. Low power consumption.

Applicable materials and industries

1. Used for fields with higher requirements in depth, smoothness and precision;

2. Used to engrave metallic and non-metallic materials, for example, stainless steel decorating parts for handsets, clocks, watches, moulds, ICs, handset buttons, bitmap marking etc.

Technical specifications

|

Model |

HW-UV-A3 |

|

Laser wavelength |

355nm |

|

Laser power |

3W |

|

Repeating Frequency |

8-100 KHz |

|

Beam Quality |

M<1.4 |

|

Marking Range |

100mm x 100mm |

|

Marking Speed |

7000mm/s |

|

Min.line Width |

0.01mm |

|

Min.Character |

0.1mm |

|

Repeatability Accuracy |

±0.002mm |

|

Power Supply |

220V±10% / 50-60Hz / 10A |

|

Power Consumption |

200W |

|

Weight |

40kg |

|

Operating System |

Industrial computer, Win 10 |

|

Cooling Way |

Air cooling |

Laser marking machine configuration:

|

Laser source 3W.5W.10W |

Ultraviolet laser source made in China |

|

Scanning head |

Scanquick Ⅲ pure digital high speed galvanometer |

|

Focal lens |

Wavelength |

|

Software |

EZCAD |

|

Computer |

Standard computer, win 10 |

|

Control card |

JCZ card/USC-1 |

Sample display