Fiber laser marking machine,also called fiber laser engraving machine,fiber laser output the laser, and then optical fiber transmission to scanning galvanometer system,focused laser acts on the product material,realizes the marking function.

The fiber laser marking equipment has high electro-optical conversion efficiency, air-cooling way,small size, and the output beam quality is good. High reliability,long operating lifetime, energy saving, can engrave metal materials and some non-metal materials.

Laser engraving for production molds,PC boards,LED light bulbs, pistons, piston rings, valves, valve seats, hardware tools, sanitary ware, electronic components, plastic and other surfaces.

Laser marking machine configuration:

| Laser source | 20w,30w,50w,100w;Max or JPT,or IPG made in Germany |

| Scanning head | HY head,or Scanlab head |

| Focal lens | Wavelength |

| Software | EZCAD |

| Computer | Standard computer,win 10 |

| Control card | JC card/USC-1 |

| Plug | USA Standard |

| Foot pedal | One pedal |

| Body bracket | Metal bracket |

Technical specification:

| Model | HW-MK-AT01 |

| Laser Power | 20W |

| Laser wavelength | 1064nm |

| Repeating Frequency | 20~120 KHz |

| Beam Quality | M<1.8 |

| Marking Range | 100*100mm/200*200/300*300mm |

| Marking Depth | 0.1~1.5 mm(depend on material) |

| Marking Speed | 10,000mm/s |

| Min.line Width | 0.01mm |

| Min.Character | 0.15mm |

| Repeatability Accuracy | ±0.002 |

| Power Supply | 220V±10% / 50Hz |

| Power Consumption | 800W |

| Machine Weight | 120KGS |

| Operating System | Win 10 |

| Cooling Way | Air cooling |

| Control Interface | Standard USB |

| Laser Type | Pulse |

| Laser source | MAX/JPT/RAYCUS/IPG |

| Laser head | High precision galvanometer |

Characteristics:

1. High efficiency in electrical / optical conversion, wind cooling ;

2. Small size, with high beam output quality, high reliability;

3. The marking speed is 3~12 times of first and second generation of laser markers;

4. No consumable,long term service life of the laser source,energy saving;

5. Low power consumption(800W).Applicable materials and industries:

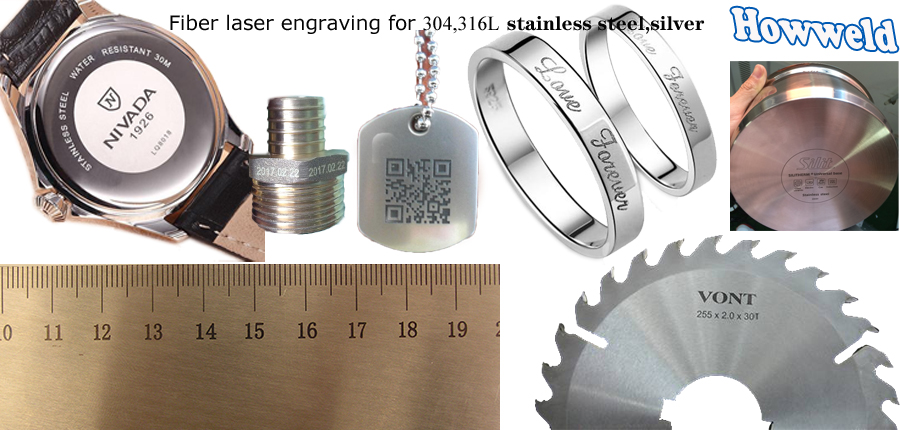

1.Marking for metallic and non-metallic materials,such as stainless steel,aluminum,brass,decorating parts,handsets, clocks, watches, moulds, ICs, handset buttons, bitmap marking etc.

2.Engraving for eyewear frames,metal sheets,TR,rubber,optic lens.

Samples display: