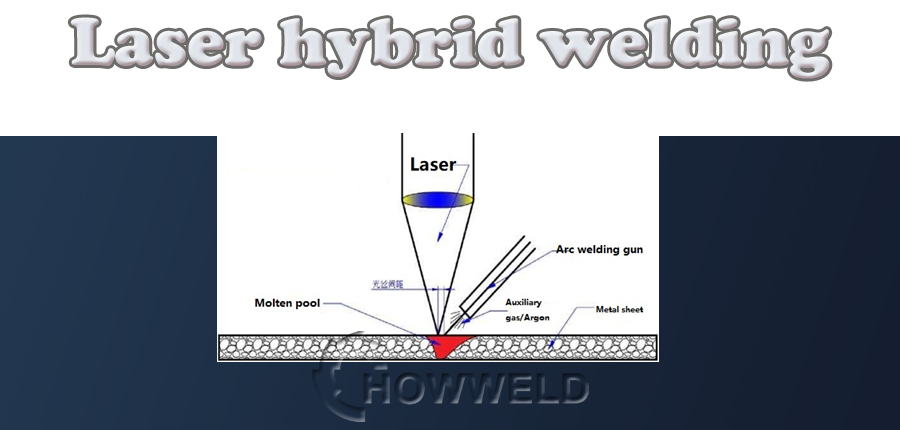

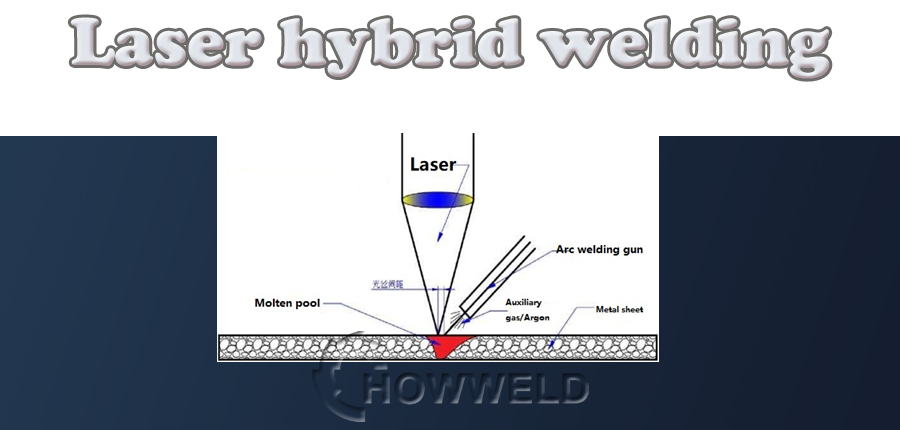

Howweld great design fiber laser hybrid welding technology combines the deep weld penetration and low heat input associated with laser welding with the excellent weld properties and superior gap tolerance of gas metal arc welding.

Laser hybrid welding system configuration

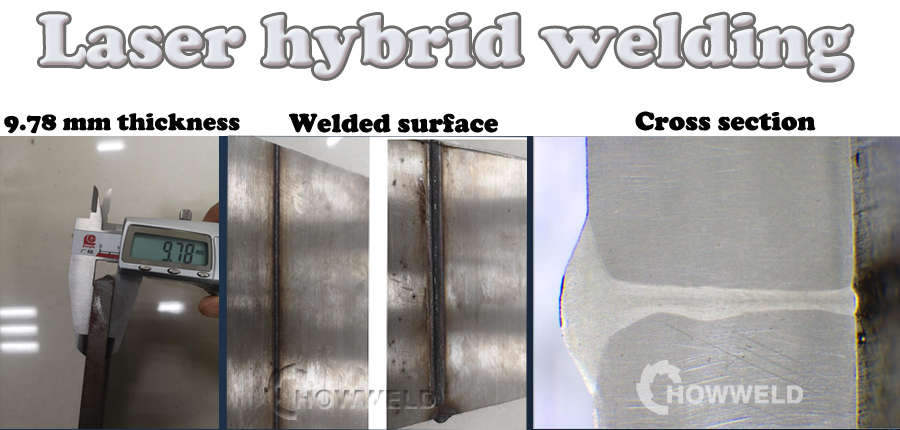

A radically new welding alternative, it produces extremely narrow and deep welds at very high travel speeds. In a single pass, the process can often achieve what might require multiple weld passes using a conventional fusion welding process.

Heat input to the part is reduced, as is the associated weld shrinkage and distortion that can make postwelding geometry unpredictable - and costly to repair.

Using gas metal arc welding in combination with a laser, the process overcomes the limitations of laser-only welding with its ability to produce quality welds in joints with less-than-perfect fitup between parts.

This enables a widened, more robust process envelope by a factor of three compared to a conventional laser-only process.

This enables a widened, more robust process envelope by a factor of three compared to a conventional laser-only process.

ARC welding also allows users to add filler metal to adjust the welds metallurgical properties and create beads and fillets, while the slower cooling rate reduces hardness. These features are especially beneficial when joining high performance carbon and stainless steels.

Howweld team exclusive adaptive closed-loop control system detects joint fit-up conditions and changes the process parameters in real-time to achieve a constant weld profile. This broadens the process window by a further 5 times over non-adaptive control.

Features

The Advantage:

Operating costs reduced by 50-80%.

Productivity improved by 300-1000%.

Heat input and distortion reduced by 80-90%.

Reduced weld repair rates.

[We "Howweld team""www.howweld.com" are trying many new technology during 2021,2022, promote new technology to Asia countries first,then European countries]

Reduced labour content through fully automated operation.

Reduced operator skill requirement due to simple, PC-machine controller.

Lower downstream assembly, welding and finishing costs, through reduced part distortion.

Higher overall plant throughput and revenue generation.

Feasibility of new, lighter, stiffer and simpler product design and construction methods.

Full backing and support of howweld team process experts and service professionals, with extended warranty and service agreements.

Laser hybrid head conbine laser welding head with MIG lincoln head

Laser hybrid head conbine laser welding head with MIG lincoln head

Connect together laser hybrid head

Samples testing: