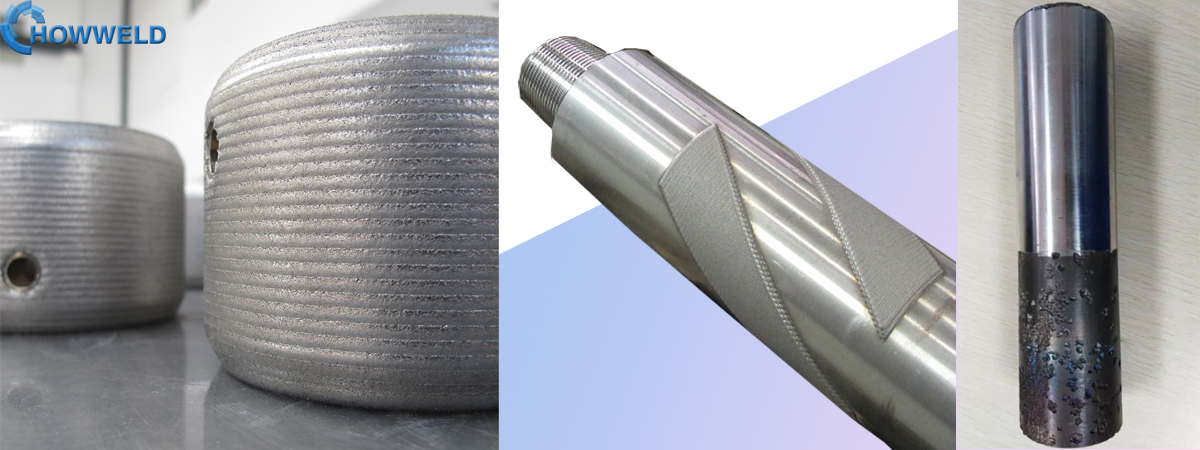

Application:

1. Metal surface repair

2. Automobile manufacturing

3. Mould industry

4. Petroleum equipment

5. Aviation manufacturing

6. Railway equipment

7. Spray barrel repairing

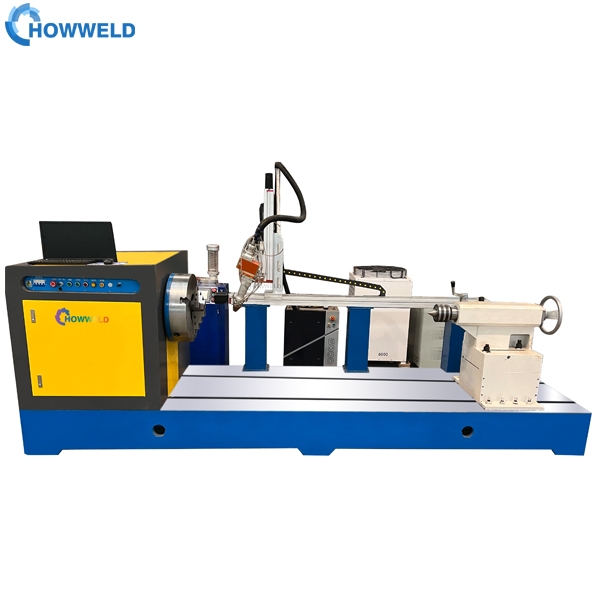

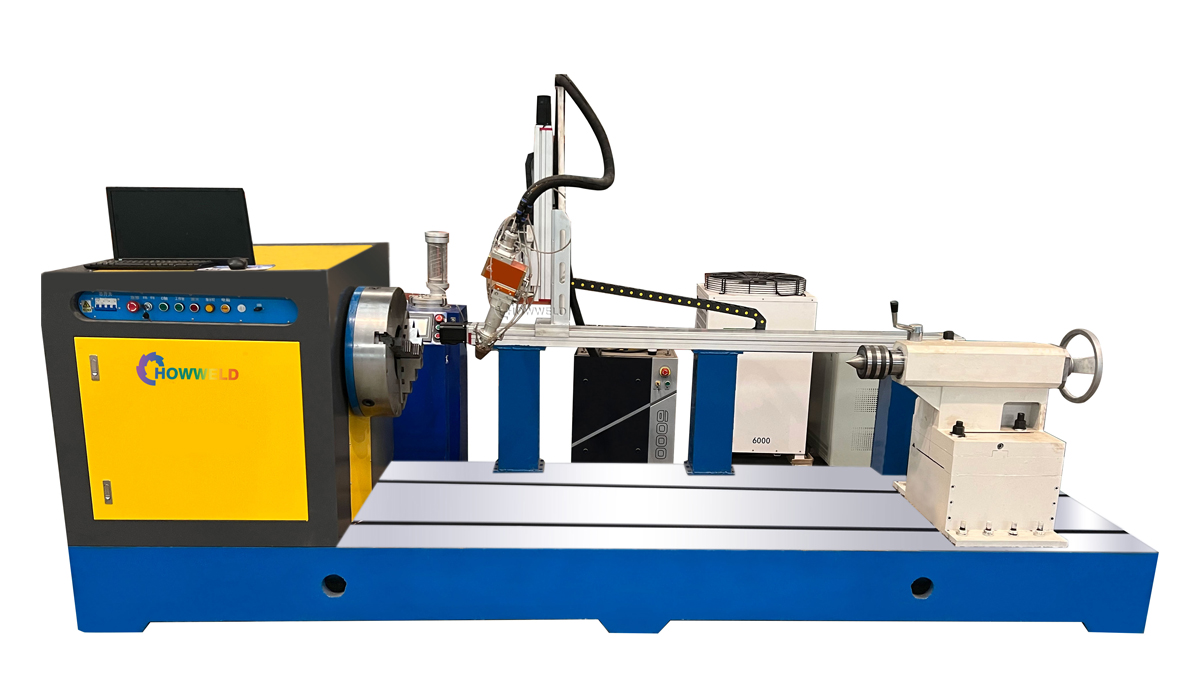

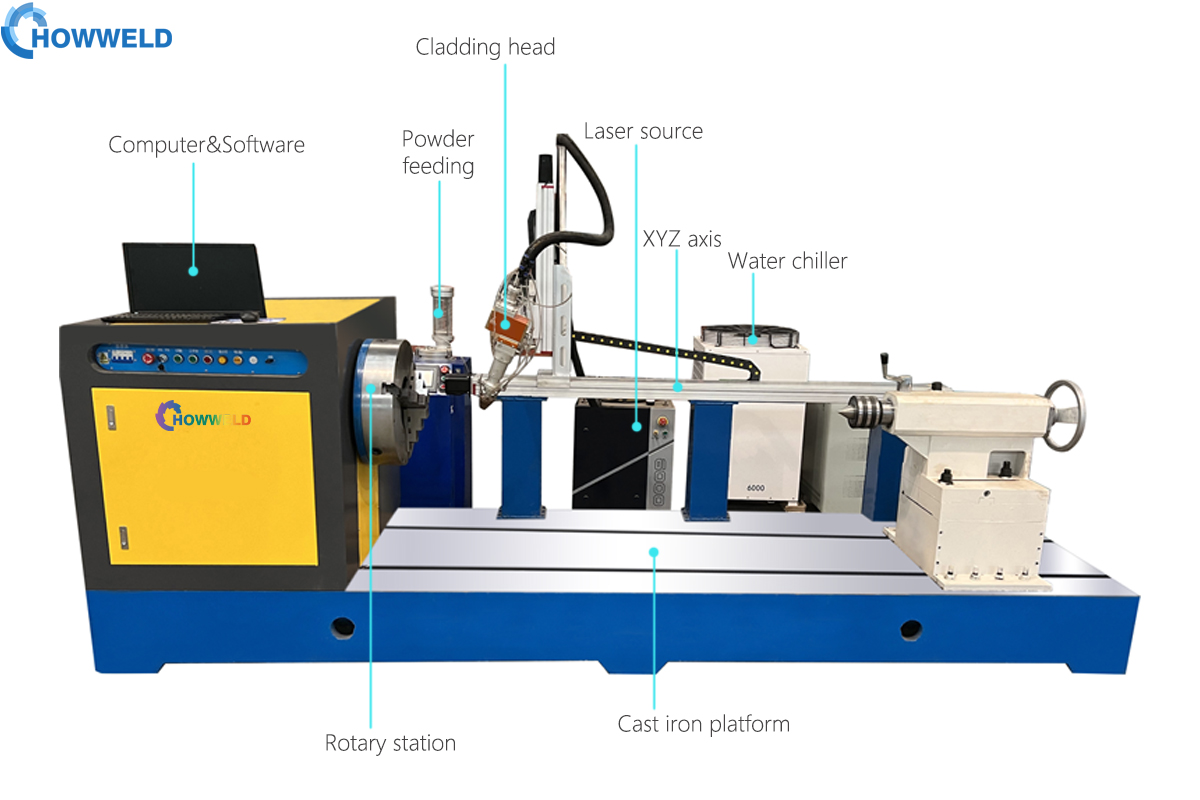

Main configurations:

| Description | Model |

| Fiber laser source | Continuous type 3000W 6000W 8000W |

| Laser cladding head | Circular spot 3mm 4mm 6mm |

| Water cooling system | Capacity 12KW |

| Rotating platform | Motor 9kw, X Y Z Axis 4.5*0.5*0.5 meter |

| Control system | CNC2000 |

| Powder feeder system | Single barrel powder feeder optional double barrel |

| Power supply | 380V, 50Hz/60Hz |

| X Y Z Rail | Hiwin brand |

| Voltage pressure regulator | Match for 6KW machine |

Powder feeder:

We have developed the third generation scraper type accurate powder feeder.

The powder feeder has the advantages of excellent manufacture, good powder feeding continuity, high precision, simple structure (only one independent moving part) and long service life.

It is especially suitable for laser cladding equipment.

| Description | Parameters |

| Powder feeding (g/min) | 1~40 |

| Powder feeding accuracy (%) | 1% |

| Capacity of powder storage tank (kg) | 10~20 |

| Particle size (mesh) | 80~550 |

| Powder gas flow (m3/h) | 0.1~0.4 |

Samples:

.jpg)