Machine introduction:

Circuit board laser cutting machine: it adopts high-performance UV / green laser, with good beam quality, small focusing spot and uniform power distribution. It can process all kinds of high complexity circuit boards, flexible circuit boards and soft and hard combination boards. Meet the high-yield and high-efficiency demand of cutting and processing mass production in circuit board industry.

Basic functions:

1.Laser drilling through holes and blind holes.

2. Laser processing large positioning holes.

3. Laser cutting any irregular contour.

Technical specifications

|

Model

|

HW-UV-15W

|

|

Laser Power

|

15 W

|

|

Laser wavelength

|

355 nm

|

|

Repeating Frequency

|

15-100K HZ

|

|

Beam Quality

|

M<1.1

|

|

Cutting Range

|

500*600mm Customized

|

|

Marking Speed

|

10mm/s

|

|

Min.line Width

|

0.01mm

|

|

Min.Character

|

0.15mm

|

|

Repeatability Accuracy

|

±0.02

|

|

Power Supply

|

220V±10% / 50-60Hz / 10A

|

|

Power Consumption

|

3000W

|

|

Weight

|

≤250kg

|

|

Operating System

|

Win 7

|

|

Cooling Way

|

Water cooling

|

|

File Format

|

DXF,PLT

|

Laser cutting machine can process a variety of materials, metal copper, resin coated copper sheet, FR4, FR5, PI, etc.

High quality UV laser to minimize the thermal effect during cutting and drilling,

High processing precision, neat edge, no burr, no residue, and no separation from the substrate.

The laser circuit board laser cutting machine adopts high-performance ultraviolet or green laser, with good beam quality, small focusing spot, uniform power distribution, fast cutting speed and stable performance, which can meet the high-yield and high-efficiency requirements of cutting and processing in the circuit board industry.

Advantage:

The UV laser cutting machine has high machining accuracy, the minimum focusing spot can be less than 10 microns, high machining position accuracy and small cutting gap;

The heat effect is small, the carbonization degree of processed materials is low, there is no visible carbonization with the naked eye, and some materials are completely carbonized;

It can process any graphics, import graphics by software, and grab rake processing at camera point without mold opening operation. It is very simple and the method is simple and easy to understand;

The cutting edge shall be smooth and neat without burr;

Easy automation, high flexibility, one machine with multiple functions;

High flexibility and wide application range;

The equipment has no consumables and special fixtures, which is conducive to improving the competitiveness of products.

Shortcoming:

In addition, the investment cost is higher. Compared with the traditional mold processing method, the efficiency in the process of mass processing is lower, and only thinner materials can be processed.

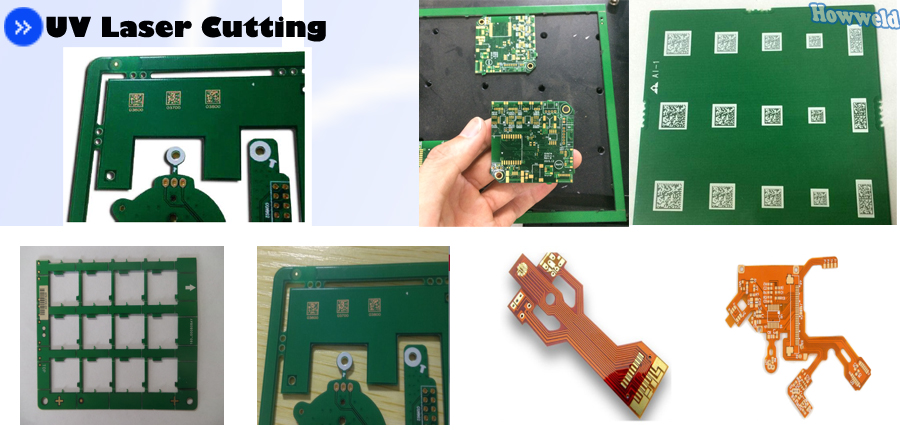

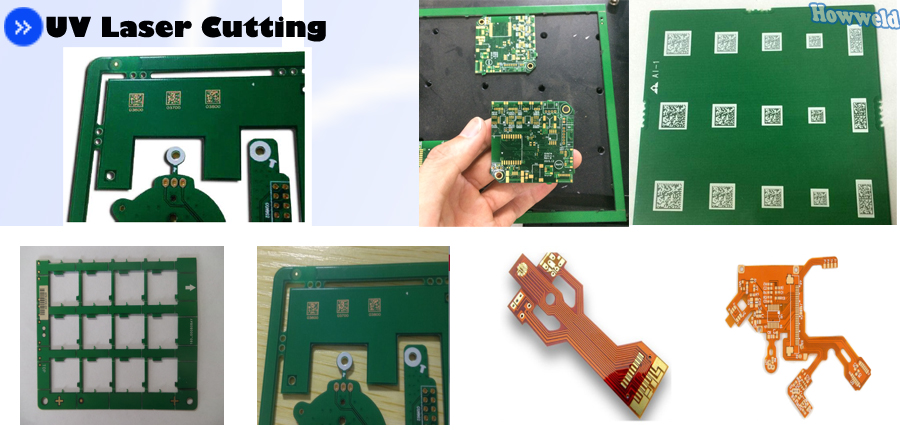

Sample display:

Sample display: