CNC Fiber Laser Welding Machine | Automatic Laser Welding Machine

Brief introduction:

Fiber CNC laser welding machine with mid size table or large X,Y,Z,A,B axis moving,can weld 180°angle of products.It is a kind of laser welding equipment that couples a high-energy laser beam into an optical fiber, transmits the laser through the optical fiber, and focuses on the workpiece to perform welding. For parts that are difficult to be welded, the simple universal instrument can be used to dock large molds and difficult-to-access precision parts, and implement flexible transmission non-contact welding, which has greater flexibility. The laser beam can split the light in time and energy, and can process multiple beams at the same time, which provides conditions for more precise welding.

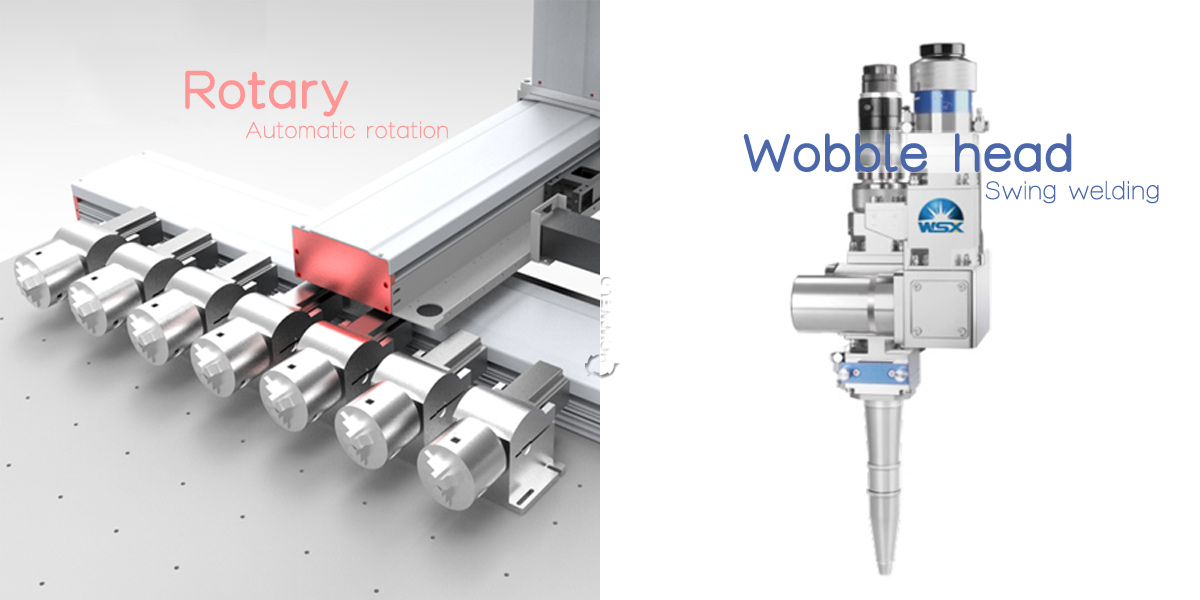

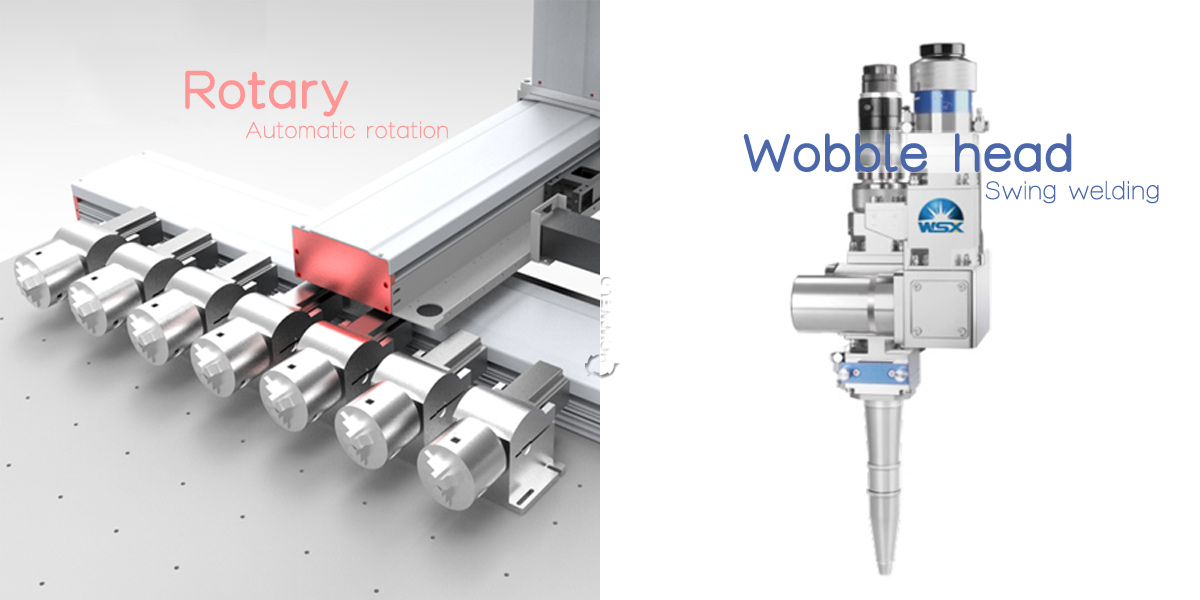

The fiber laser welding system can install with X,Y,Z axis moving table,and intall with robot arm too.

Working table range can matching 800*500mm,or 1000*500mm etc.

Technical specification:

Which power machine should choose:

The fiber laser welding system can install with X,Y,Z axis moving table,and intall with robot arm too.

Working table range can matching 800*500mm,or 1000*500mm etc.

Automatic laser welding machine configuration:

| Laser source | Fiber laser source |

| Wobble Laser head | Made in China |

| Cooling water chiller | S&A |

| Welding software | Matching with laser head |

| Safety system | Closed circuit system |

| Observing system | CCD Visual |

| Rotary | Optional |

Technical specification:

| Model/Power | 1000W | 1500W | 2000W |

| Max energy of single pulse | 75J | 110J | 120J |

| Laser type | CW Contunuous laser |

||

| Laser wavelength | 1064nm |

||

| Laser frequency | 1~5000Hz |

||

| Laser spot diameter | 0.4~2mm |

||

| Welding penetration | 0.1~3mm |

||

| Power adjust range | 5%~100% |

||

| Pulse width | 1ms |

||

| Power supply | 220V/50-60Hz | 220V/50-60Hz | 380V/50-60Hz |

| Power consumption | 5KW | 7KW | 11KW |

| Cooling way | Water cooling |

||

| Weight | 350KG | 390KG | 425KG |

| Chiller‘s water type | Deionized water |

||

| Protective gas | Nitrogen gas | Nitrogen gas | Nitrogen gas |

| Protective gas pressure | 12~14 MPa | ||

Which power machine should choose:

| Thickness/Materials | Stainless steel | Carbon steel | Aluminium |

| 0.4~1.9mm thickness | 1KW | 1KW | 1KW |

| 2~4mm thickness | 1KW | 1.5KW | 2KW |

Advantages:

1.Russian laser source,high photoelectric conversion efficiency;

2.The life of the device is prolonged and the daily maintenance is more convenient;

3.The processing is non-pollution,the heat affected zone is small, and the deformation is small;

4.The welding seam is thin,large depth,the taper is small,the precision is high,and the appearance is smooth,flat surface and beautiful;

5.It is controlled by a PC and assisted by special software,which is simple and easy to learn;it can cut or weld any graphic characters or punch holes;

6.No consumables, small size,flexible processing, low operating cost;

7.Optical fiber output,can be equipped with manipulator or assembly line;

8.CCD monitoring and observation system which can clearly observe the product positioning and welding effect according to the red light indication.

9.Can be equipped with assembly line or robotic arm.

Applicable materials and industries:

Widely used in welding optical communication devices, smart watch metal connectors, mobile phone accessories (medium plates, nuts), batteries, optical fiber coupling devices, kinescope electron guns, connectors, microelectronic components, medical equipment, precision parts, etc. Mainly used for continuous welding of various metal plates (copper, aluminum, titanium, stainless steel, low carbon steel, etc.).

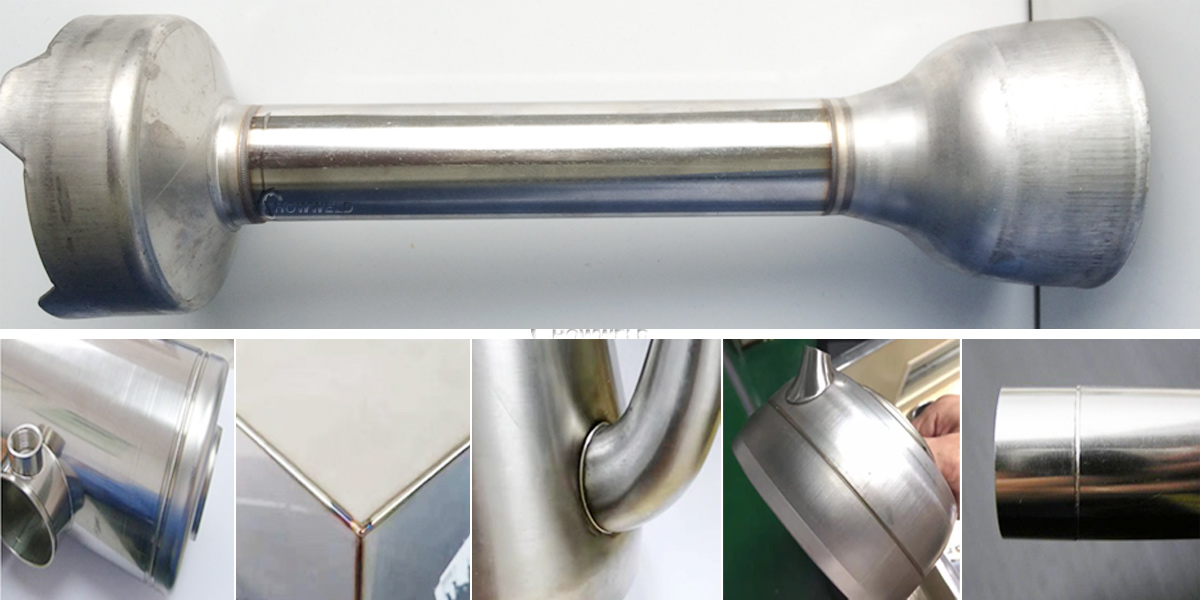

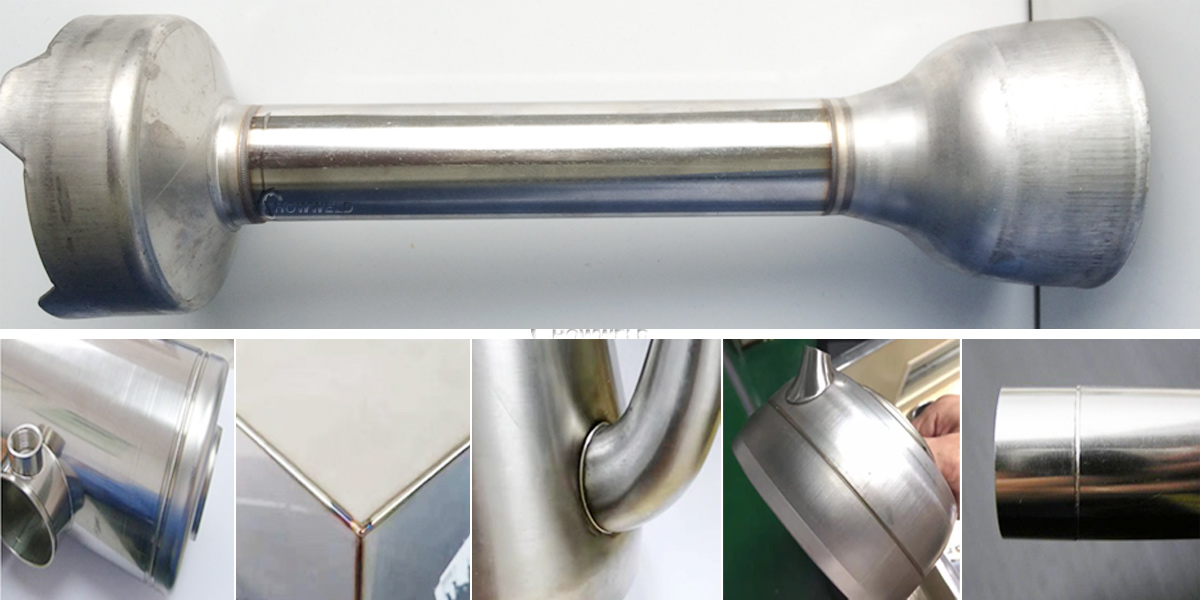

Samples display:

Samples display: