Technical of laser cladding system

Laser cladding refers to placing the selected coating material on the surface of the cladding substrate in different feeding methods, and irradiating it with a laser to melt it and a thin layer on the surface of the substrate at the same time, and rapidly solidify to form a very low dilution.

The surface coating, which is metallurgically combined with the substrate, significantly improves the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the substrate surface, to achieve the purpose of surface modification or repair, which not only satisfies the specific requirements of the material surface Performance requirements, and save a lot of valuable elements.

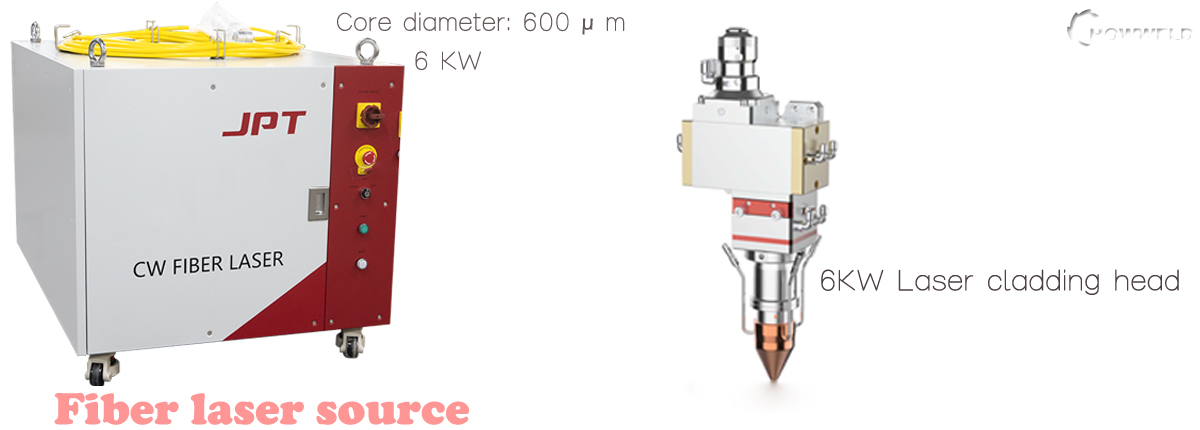

The 6000W optical fiber cladding system complete set is large-scale integrated equipment integrating optical, mechanical, electrical, refrigeration and material processing technologies. The equipment has functions such as laser cladding, laser cladding, and laser alloying. Among them, the 6000W fiber laser cladding system has the ability to be moved to the site for laser processing.

Laser cladding is the main alloy of the alloy powder that needs to be melted into the cladding layer without laser. The cladding layer and the base metal are melted in a thin layer to form a metallurgical combination of laser surface repair treatment technology.

The high energy density and high directionality of the laser can be used to treat the inner surface of the tubular material, so that the performance of the inner surface of the tubular workpiece can be improved, especially the hardness, strength, wear resistance, corrosion resistance and high temperature resistance of the inner surface. Thereby increasing the service life of the tubular material.

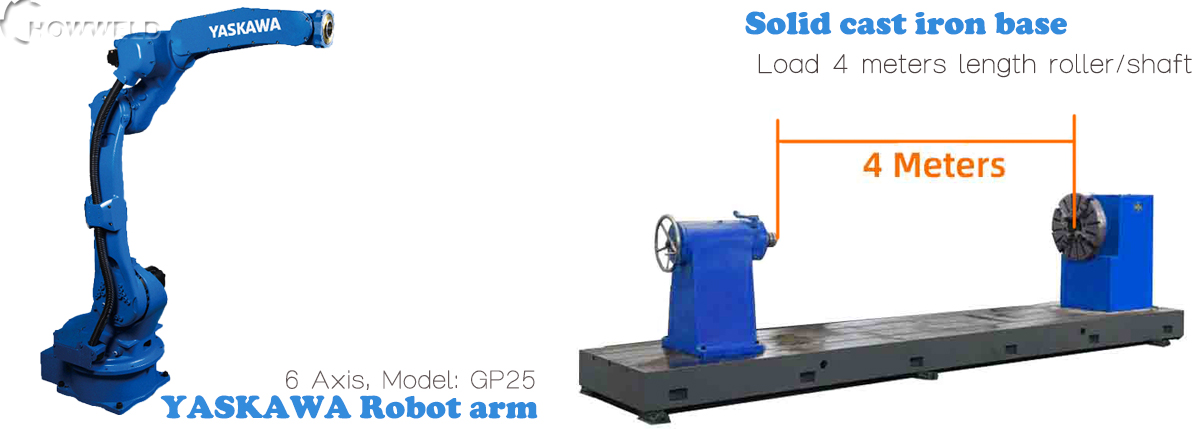

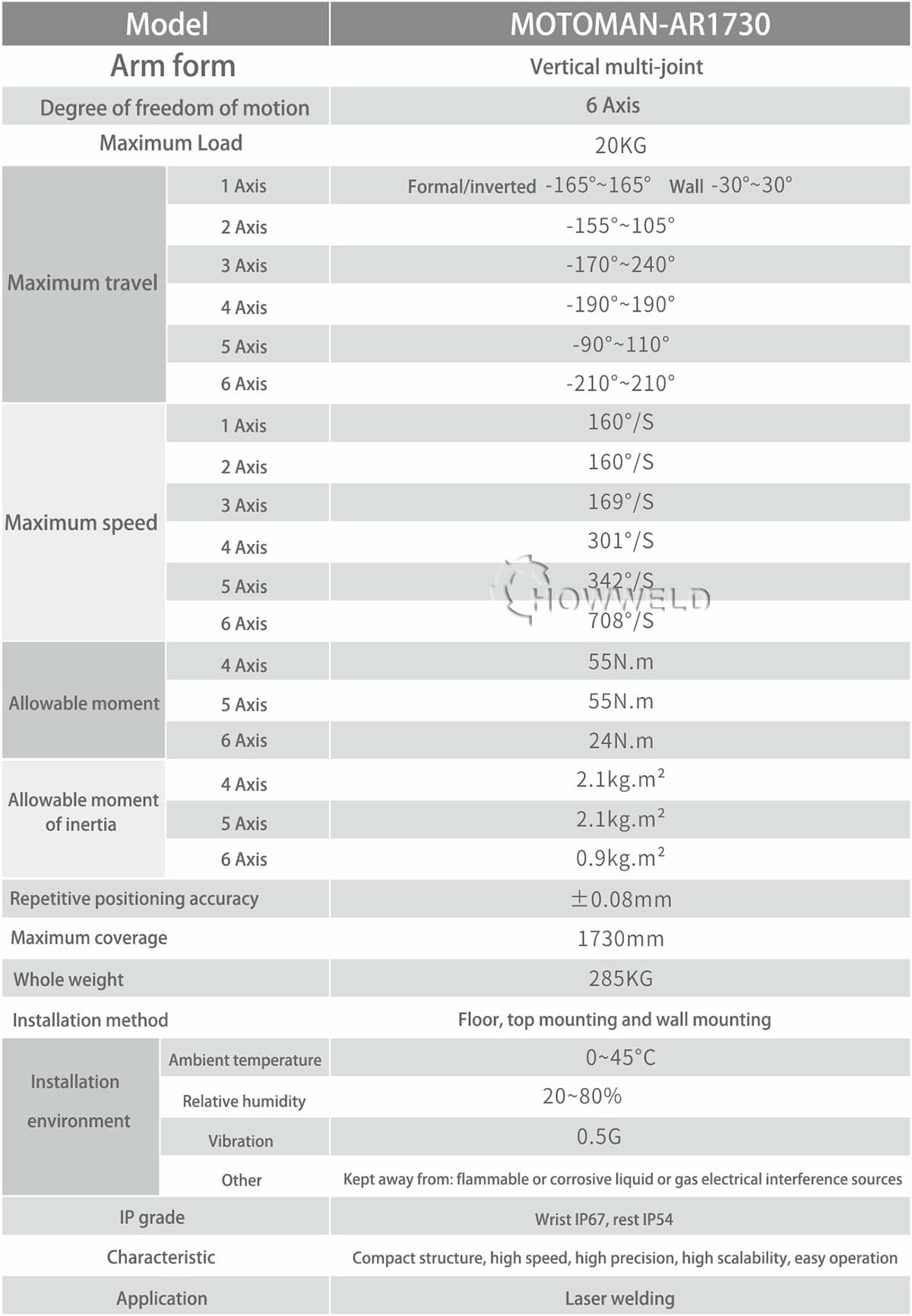

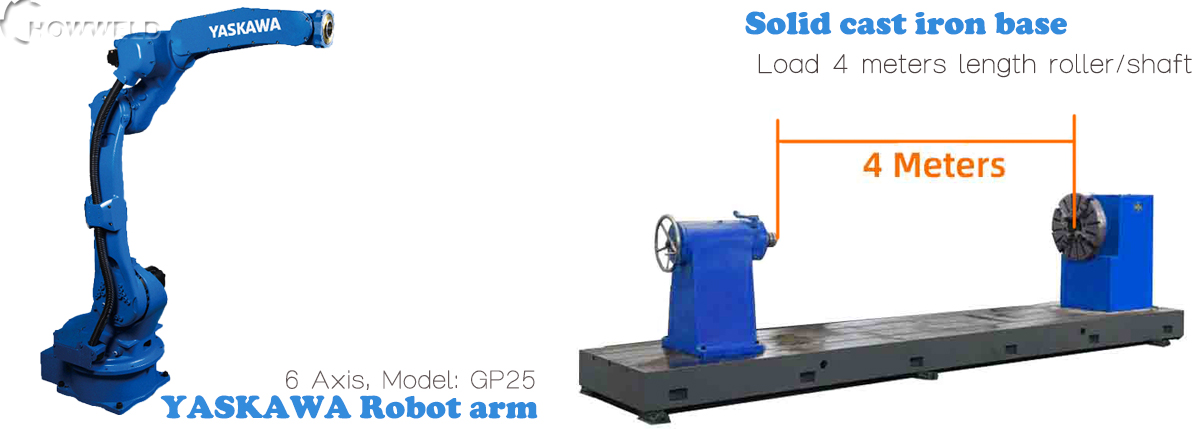

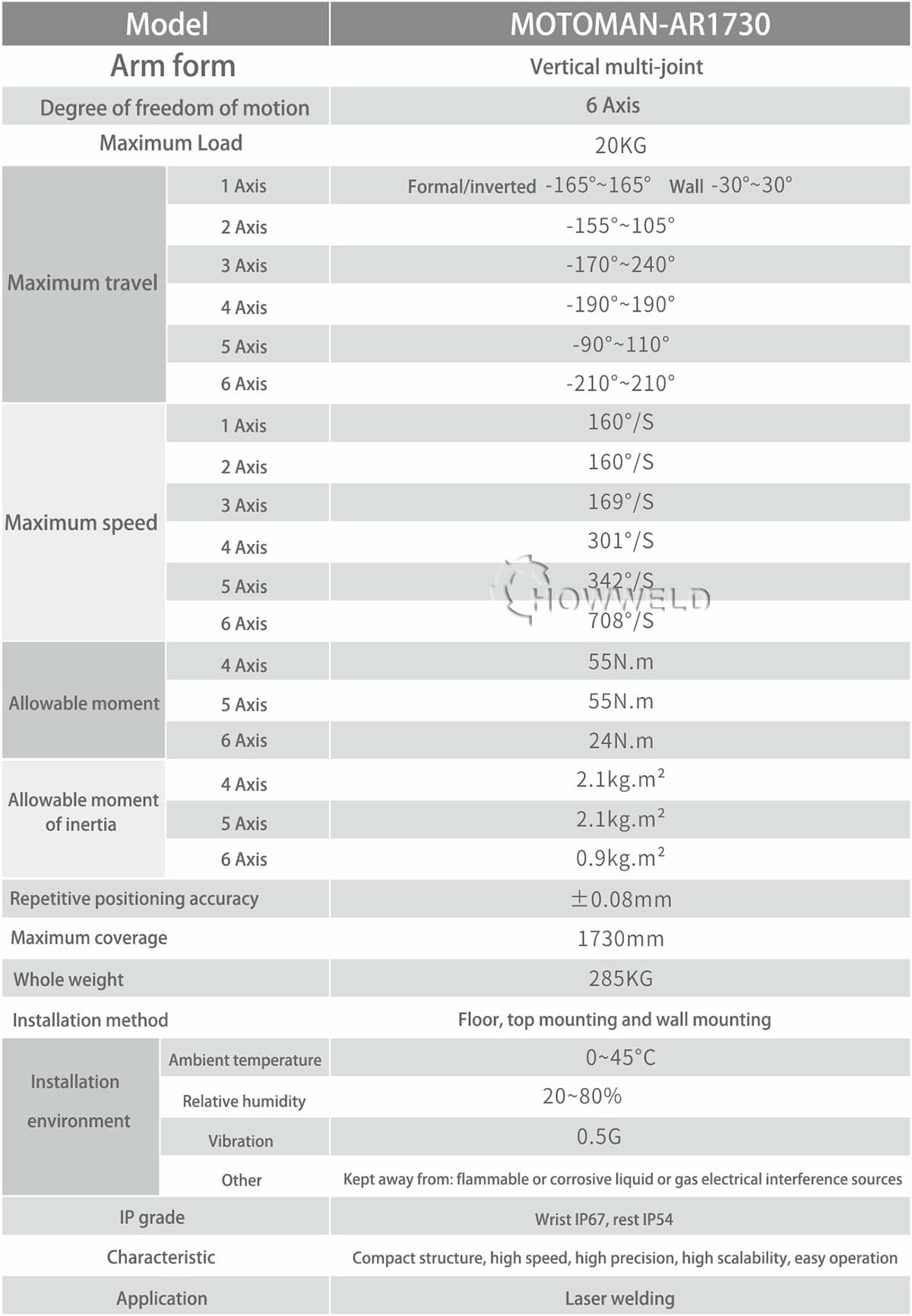

Robot arm data

Main configurations:

Powder feeder:

We have developed the third generation scraper type accurate powder feeder.

The powder feeder has the advantages of excellent manufacture, good powder feeding continuity, high precision, simple structure (only one independent moving part) and long service life.

It is especially suitable for laser cladding equipment.

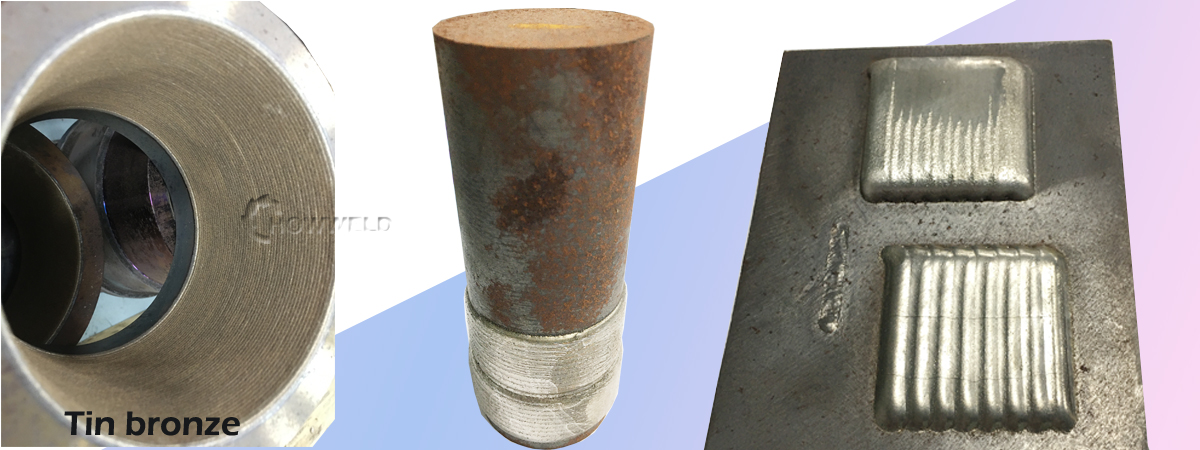

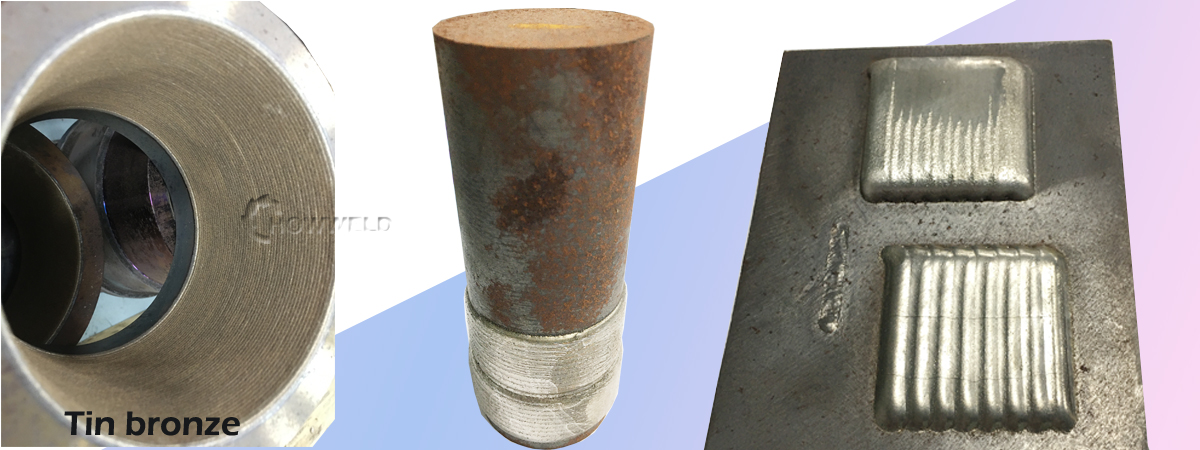

Samples:

Robot arm data

Main configurations:

| Description | Model |

| Fiber laser source | Continuous type 6000W |

| Laser cladding head | Circular spot 4mm 6mm |

| Water cooling system | Capacity 12KW |

| Rotating platform | X Y Z Axis 2*0.5*0.5 meter |

| Control system | CNC3000 |

| Powder feeder system | Single barrel powder feeder |

| Power supply | 380V, 50Hz |

| X Y Z Rail | Hiwin brand |

| Voltage pressure regulator | 6KW power machine match |

Powder feeder:

We have developed the third generation scraper type accurate powder feeder.

The powder feeder has the advantages of excellent manufacture, good powder feeding continuity, high precision, simple structure (only one independent moving part) and long service life.

It is especially suitable for laser cladding equipment.

| Description | Parameters |

| Powder feeding abount (g/min) | 1~40 |

| Powder feeding accuracy (%) | 1% |

| Capacity of powder storage tank (kg) | 5~50 |

| Particle size (mesh) | 80~350 |

| Powder gas flow (m3/h) | 0.1~0.4 |

Samples: