Laser hardening metal surface strengthening technology

Mold surface laser quenching is a new type of metal surface strengthening technology. It can overcome the shortcomings of traditional metal surface strengthening processes, such as carburizing and quenching, induction hardening, etc., such as uneven distribution of hardened layers and large deformation. Technology is a high-tech with great development prospects.

In order to improve the bearing capacity of the metal surface, the metal needs to be surface-hardened.

The traditional surface hardening treatment processes such as carburizing, nitriding and other surface chemical treatments, induction surface quenching, flame surface quenching, etc., all have problems such as large deformation after heat treatment. Thus affecting the accuracy and service life. Using laser quenching, its heating and cooling speed is very high, no external quenching medium is required, the workpiece deformation is small, the working environment is clean, and the finishing process is not required after treatment.

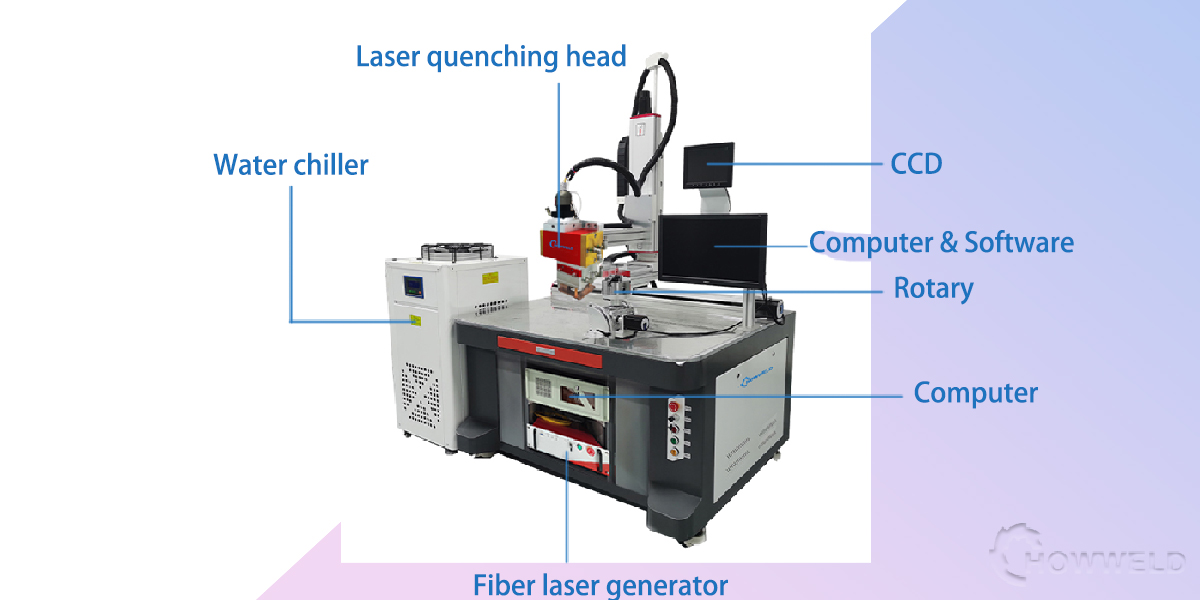

Main configurations:

Main configurations:

| Description | Model |

| Fiber laser source | Continuous type 3KW/6KW |

| Laser quenching head | Scanning lenth 18mm |

| Rotary moving table | X Y Z Axis 2*0.5*0.5 meter |

| Water cooling system | Capacity 12KW |

| Control system | CNC 3000 |

Parameters:

| Laser power | 3000W 6000W |

| Laser wavelength | 1080 nm |

| Working model | CW continuous |

| Machine power | 9KW 18KW |

| Scanning positioning | Cross red light |

| Optional platform | Robot arm, XYZ moving table, Rotary axis |

6000W machine quenching capacity:

| Machine power | 6000W |

| Scanning width | 20mm |

| Materials | Die Steel, Cast Iron, Chrome Steel |

| Quenching depth | 1mm |

| HRC | 80 |

Application:

1. Large workpieces that are difficult to enter the heat treatment furnace.

2. Workpieces that only need to be heat treated on local surfaces such as grooves, grooves, holes, edges, and cutting edges.

3. The parts that are difficult to be treated by conventional heat treatment process.

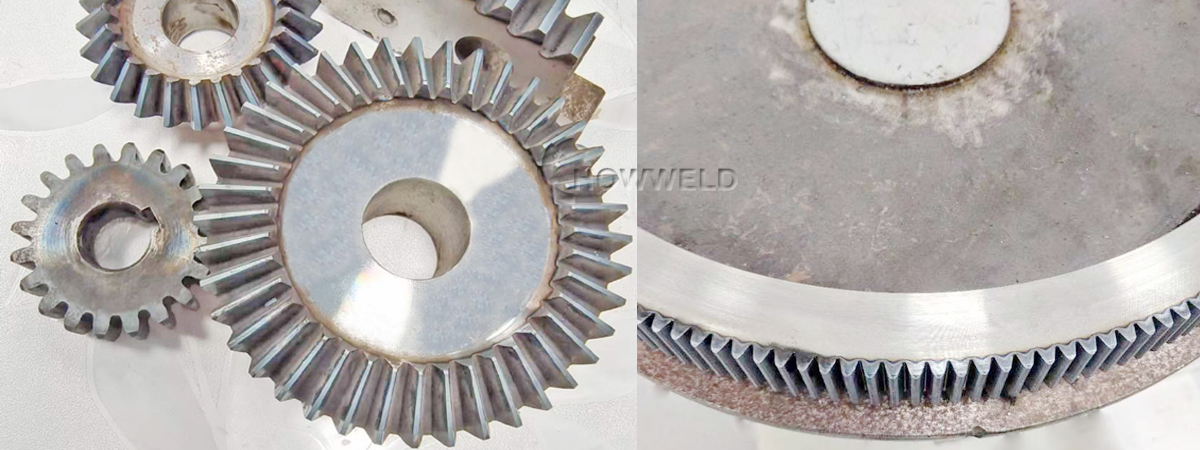

Sample display: