Main parts

|

Main parts: |

Brand Details: |

|

Laser source |

Max,Raycus or KWT |

|

Handheld gun/Laser head |

Made in China |

|

Cooling chiller |

Made in China |

|

Welding software |

Made in China |

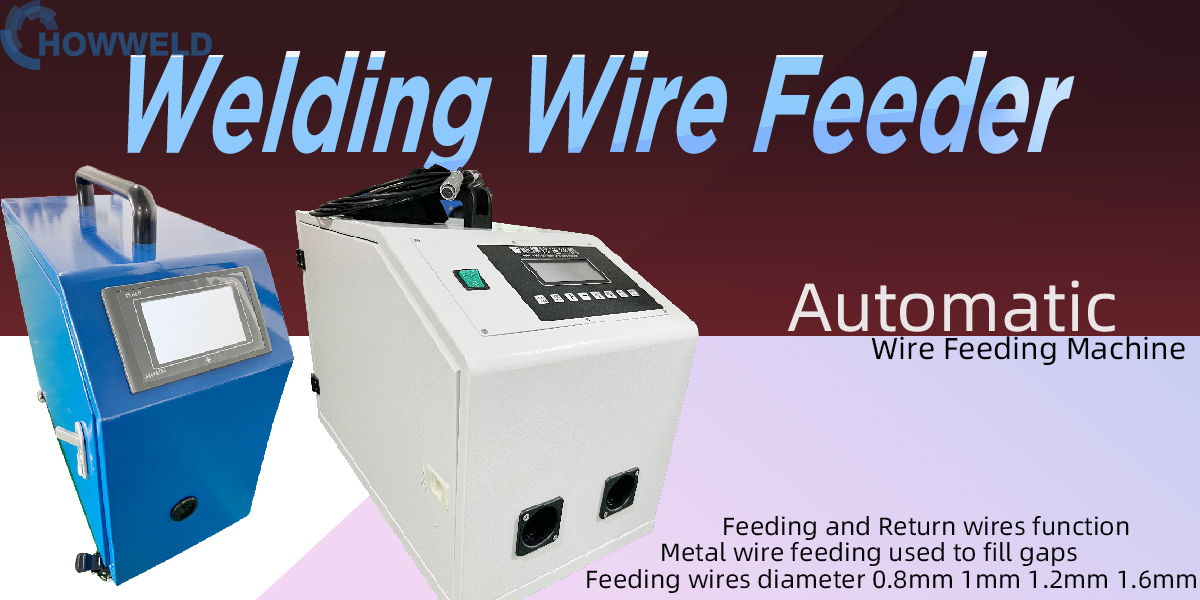

Single wire feeder:

|

2000W |

|

||||||

|

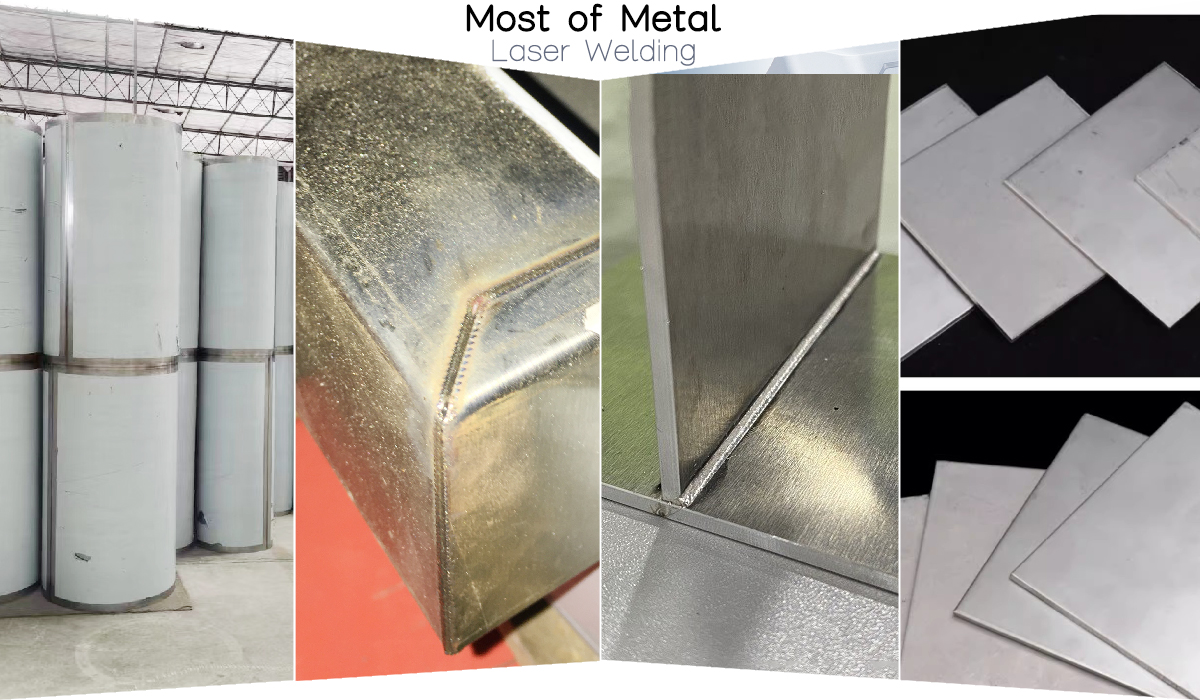

Materials |

Stainless steel |

Carbon steel |

Aluminium |

Brass |

Red copper |

||

|

Thickness-mm |

|||||||

|

0.5 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

||

|

0.8 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

||

|

1 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

||

|

1.5 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

|

||

|

2 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

|

||

|

2.5 |

Weld OK |

Weld OK |

Weld OK |

|

|

||

|

3 |

Weld OK |

Weld OK |

Weld OK |

|

|

||

|

3.5 |

Weld OK |

Weld OK |

|

|

|

||

|

4 |

Weld OK |

Weld OK |

|

|

|

||

|

6 |

Weld OK |

Weld OK |

|

|

|

||

|

HOWWELD_2024 |

|||||||

|

3000W |

|

||||||

|

Materials |

Stainless steel |

Carbon steel |

Aluminium |

Brass |

Red copper |

||

|

Thickness-mm |

|||||||

|

0.5~2 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

||

|

3 |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

Weld OK |

||

|

4 |

Weld OK |

Weld OK |

Weld OK |

||||

|

5 |

Weld OK |

Weld OK |

Weld OK |

|

|||

|

6 |

Weld OK |

Weld OK |

Weld OK |

|

|||

|

7 |

Weld OK |

Weld OK |

|

|

|

||

|

8 |

Weld OK |

Weld OK |

|

|

|

||